|

|

C000 General Information

C010 General Mailability Standards

Summary

C010 describes the minimum and maximum dimensions for a mailpiece. It details the kind of container to use for a parcel and proper ways to seal and reinforce your mailpieces. The proper packaging of books, high-density items, magnetic tapes, and other odd-size mail is also described.

1.0 Minimum and Maximum Dimensions

1.1Minimum

[8-10-03] For mailability, the following standards apply:

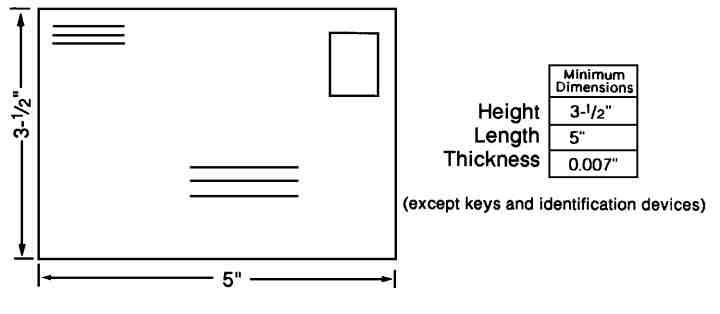

a. All mailpieces (except Customized MarketMail pieces mailed under E660 and keys and identification devices mailed under E130) that are 1/4 inch thick or less must be rectangular, with four square corners and parallel opposite sides.

b. All mailpieces must be at least 3-1/2 inches high and at least 5 inches long (see Exhibit 1.1).

c. All mailpieces must be at least 0.007 inch thick.

1.2Maximum

No mailpiece may weigh more than 70 pounds. Except for Parcel Post (see C700), no mailpiece may measure more than 108 inches in length and girth combined. Length is the distance of the longest dimension as determined by 1.3, and girth is the distance around the thickest part.

1.3Length and Height

The location and orientation of the delivery address on a mailpiece generally establish which dimensions of the piece are the length and the height. The length is the dimension parallel to the address as read; the height is the dimension perpendicular to the length; the top and bottom of the piece are the upper and lower edges, respectively, when the address is positioned for normal reading. This general rule does not apply to:

a. Automation rate flats.

b. Standard Mail Enhanced Carrier Route flats.

c. [8-10-03] Standard Mail Customized MarketMail.

d. Pieces thicker than 1/4” that are not prepared and mailed as a flat.

1.4Other Limits

Mail of some classes or at certain rates may be subject to higher minimum and/or lower maximum limits on size and/or weight as described in this part.

1.5Nonmailable

Except for keys and identification devices, all pieces not meeting the minimum size standards above are nonmailable.

Exhibit 1.1Minimum Dimensions, Pieces 1/4"

Thick or Less

2.0 Packaging

2.1Adequacy

Articles presented for mailing must be prepared under the general and specific standards in this document. The USPS accepts properly packaged and marked parcels but reserves the right to refuse nonmailable or improperly packaged articles or substances. Additional or other standards can apply to overseas military post offices and international mail.

2.2Acceptability

No item may be packaged so that its contents could harm employees, equipment, or other mail. Fragile items must be packaged to withstand mail processing and transportation. Heavy items must be braced and cushioned to prevent damage to other mail.

2.3Stationery

Stationery-type items thicker than 1 inch or heavier than 1 pound are not accepted in letter-style envelopes. The contents of these packages must be unitized by tying, banding, or using partitions on close-fitting interior containers to prevent shifting.

2.4Liquids

Containers of liquid with only friction-top closures are generally not acceptable; screw caps, soldering, clips, or other means must be used for closure. Glass and other breakable containers of liquid with a capacity of more than 4 fluid ounces must be cushioned, with material sufficient to absorb all leakage in case of breakage, inside a sealed, waterproof container. Containers of liquid with a capacity of more than 32 fluid ounces are acceptable for mailing if cushioned as above and packaged within another sealed, waterproof container such as a can or plastic bag. The outer shipping container must be strong enough to protect the contents and must be marked to show the liquid nature of the contents. Steel pails and drums with carrying handles and positive closures, such as locking rings or recessed spouts under screw-cap closures, may be accepted without additional packing.

2.5Aerosols

Aerosols (i.e., containers under pressure) are hazardous materials (see C023) and must be constructed to prevent accidental discharge of the contents during postal handling. Mailable aerosol containers must be packaged under C023.

2.6High-Density Items

High-density items are defined as packages of solid objects other than books whose weight is comparatively high for their volume (e.g., hardware, machine and auto parts, tools). Such items weighing more than 15 pounds and packaged so that they exert no more than 60 pounds per square foot (0.4167 pound per square inch) pressure on the smallest side of the container are machinable.

2.7Infectious Substances

Infectious substances (etiologic agents), clinical specimens, and biological products must be packaged and marked as specified in C023 and C050, as applicable.

2.8Load Type

The following three terms describe types of loads, based on the content, degree of protection, and strength of the package used:

a. An easy load is one that contains items of moderate density that either completely fill the container or are packaged in interior containers that completely fill the outer mailing container. This load type is not readily damaged by puncture or shock and does not move within the package or present a hazard to other parcels.

b. An average load is one that contains moderately concentrated items packed directly into a shipping container or that are subjected to an intermediate stage of packing and providing partial support to all surfaces of the container. This load type can be prepackaged by nesting items within partitions or in separate paperboard boxes to stabilize items and prevent shifting and damage.

c. A difficult load is one that contains items that require a high degree of protection to prevent puncture, shock, or distortion to the items or the package. Fragile items, delicate instruments, and high-density, small-bulk items that do not support the mailing container are not acceptable in paperboard boxes, bags, or wraps.

2.9Preservation

The mailer must package the contents of a shipment to prevent deterioration or degradation.

3.0 Acceptable Containers

3.1Boxes

Boxes are acceptable, subject to these standards:

a. Paperboard boxes may be used for easy and average loads to 10 pounds.

b. Metal-stayed paperboard boxes may be used for easy and average loads to 20 pounds.

c. Solid and corrugated fiberboard boxes may be used according to the limits in the following chart, unless otherwise specified. The first maximum reached governs the grade of the box used.

| Maximum Weight of Box and Content (pounds) |

|||

|---|---|---|---|

| Easy or Average Load |

Difficult Load |

Maximum Length and Girth (inches) |

Box Grade |

| 20 | — | 67 | 125 |

| 40 | 20 | 100 | 175 |

| 65 | 45 | 108 | 200 |

| 70 | 65 | 108 | 275 |

| — | 70 | 108 | 350 |

d. Wood, metal, or plastic boxes may be used for all types of loads, assuming adequate construction.

e. The size of the box must be adequate to contain the items and provide enough space for cushioning material.

f. Good, rigid, used boxes with all flaps intact are acceptable.

g. Boxes with difficult loads to out-of-town destinations must be reinforced with banding about every 8 inches in each direction around the package.

3.2Difficult Load

The USPS does not accept bags, bales, or wraps with difficult loads. The contents in bags, bales, and wraps must be compressed when possible.

3.3Paper Bags and Wraps

For easy loads of up to 5 pounds, paper bags and wraps are acceptable when at least of a 50-pound basis weight (the strength of an average large grocery bag) and the items are immune from impact or pressure damage. A combination of plies adding up to or exceeding 50-pound basis weight is not acceptable. For easy and average loads of up to 20 pounds, reinforced bags or bags with a minimum of 70-pound basis weight are acceptable. Nonreinforced loose-fill padded bags are not acceptable as exterior containers, unless the exterior ply is at least 60-pound basis weight.

3.4Plastic Bags

Plastic bags must be at least 2 mil thick polyethylene or equivalent for easy loads up to 5 pounds; 4 mil thick for easy loads up to 10 pounds.

3.5Plastic Film

Heat-shrinkable plastic film—either irradiated polyethylene, linear low-density polyolefin, or copolymer—must be at least 3/4 mil thick for an easy load up to 5 pounds, and 1-1/4 mil thick for an average load up to 5 pounds. When requested, mailers must provide documentation that these types of film are being used for mailing.

3.6Cloth Bags

Cloth bags are acceptable for easy and average loads of up to 10 pounds, if the seams of the bags equal the strength of the basic material.

3.7Bales

Bales are acceptable within postal weight limits, if adequately compressed and reinforced to contain the material.

3.8Envelopes

Envelopes may be used as containers for articles if the package can reasonably be expected to be processed and delivered without damage to the contents or other mail. Letter-style (nongusseted flat) envelopes are acceptable as containers for nonrigid stationery and similar material, up to 1 pound and 1 inch thick. Larger or heavier envelopes are acceptable for easy loads up to 5 pounds if made from envelope paper equivalent to 28 substance weight or greater, or made from extra-strength materials with a Mullen strength of more than 90 pounds per square inch. Envelopes for photographic film mailers or gusseted (three dimensional) envelopes are acceptable if made from envelope paper equivalent to 24 substance weight or greater. Envelopes may be used as containers for odd-shaped items mailed at nonautomation Standard Mail rates, if the piece meets the standards for that class of mail.

3.9Fiberboard Tubes and Similar Long Packages

Fiberboard tubes and similar long packages are acceptable if their length does not exceed 10 times their girth. The strength of the tube ends must be at least equal to the tube sidewall strength, unless the contents are lightweight, rolled items. Sidewall strength is always equal to solid fiberboard 1/16 inch thick for tubes less than 18 inches long, 3/32 inch thick for tubes 18 to 32 inches long, and 5/32 inch thick for tubes more than 32 inches long. Crimped or taped end closures are not acceptable for other than lightweight rolled items. Tape must completely encircle the seams on friction slide closures of mailing tubes.

3.10Cans and Drums

Cans and drums with positive closures are acceptable. Generally, friction closures alone are not acceptable. Protruding devices, such as locking rings, must be shielded by padding to prevent injury to USPS employees, equipment, or other mail.

4.0 Cushioning

4.1Volume

Loose-fill cushioning must overfill the container before closure to hold the item and prevent its movement to an outside surface of the container or to other items in the package. Shock and pressure forces must be dissipated over as much of the surface of the item as possible.

4.2Several Items Within Container

When several items are inside a package, they must be protected from each other as well as from external forces. Concentrated heavy items must not be packaged with fragile items unless extreme care is exercised to separate them from each other. Heavy items must be adequately stabilized.

5.0 Closure, Sealing, and Reinforcement

5.1Tape

Cellophane and masking tape may not be used for closure or reinforcement of packages but may be used to augment adhesive closures on envelopes or to cover staples on bags.

5.2Paper Tape

Paper tape must be at least 60-pound basis weight kraft. The adhesives on gummed tapes must be adequately activated before application and firmly applied with the tape extending at least 3 inches over the adjoining side of the box.

5.3Tape Size

Except for pressure-sensitive filament tape, tapes used for closure and reinforcement may not be less than 2 inches (or 48 mm metric) wide. Nonreinforced plastic tapes must be at least as strong in the cross direction as in the machine (long) direction.

5.4Adhesive

Adhesives for closure on box flaps or on tapes must remain serviceable from -20 degrees to +160 degrees Fahrenheit. Hot-melt adhesive may be used if at least four strips are applied on each part of the box flap where the outer flap overlays the inner flap; each strip is 3/16 inch wide after compression; the strips are not more than 1-1/2 inches apart, with the first strip no more than 1/2 inch from the center seam; and all strips are the full width of the inner flap, unless hot-melt adhesive is applied to 25% of the area where the outer flap lies over the inner flap.

5.5Banding

When banding is used for closure and reinforcement, it must encircle the length and girth of the package at least once. If twine or cord is used for closure and reinforcement, it must be at least 20-pound tensile strength and secured at an intersection at least once on each side. Loose strapping and metal strapping are not acceptable.

5.6Staples and Steel Stitching

Staples and steel stitching are acceptable if spaced not more than 5 inches apart for easy and average loads (or 2-1/2 inches apart for difficult loads) and not more than 1-1/4 inches from the ends of the box. Boxes not meeting these requirements may be made acceptable by applying a strip of 3-inch-wide reinforced tape in the gap between the staples or by strapping to compensate for the gap in the staple closure. Improperly clinched staples in flats, envelopes, and cards are not acceptable.

6.0 Special Mailing Envelopes

6.1Window Envelope

[6-12-03] Any window envelope used for letter-size or flat-size mail claimed at any automation rate or for letter-size mail claimed at any Enhanced Carrier Route high density or saturation rate must meet the applicable standards for address and barcode placement in C840. Any window envelope used for letter-size or flat-size mail claimed at any other rate must meet the following standards:

a. The address and any barcode visible through the window must be printed on white paper or paper of a very light color.

b. A clear space of at least 1/8 inch is required between the address block and the top, bottom, and left and right edges of the address window, and must remain when the insert is moved to its full limits in each direction within the envelope to ensure efficient processing and delivery. For nonautomation rate mail, the bottom edge of the address window must not extend more than 1/8 inch into the barcode clear zone as defined in C840. All characters in the address, any optional endorsement line, and any barcode must be completely visible throughout the full range of the movement of the insert within the envelope. Any letter-size envelope containing a window that intrudes into the barcode clear zone is not eligible for MLOCR or RVE FASTforward processing options for the move update standard in A030.

c. Window cover material, if used over the address window, must be made of a nontinted clear or transparent material (e.g., cellophane or polystyrene) and must permit the address, as viewed through the window material, to meet the print-contrast ratio standards in C840 to ensure efficient processing and delivery. Glassine may be used for window cover material. All edges of the window cover material must be glued securely to the envelope. The bottom edge of an address window must be at least 1/2 inch from the bottom edge of the envelope.

d. For letter-size mail, the delivery address window must be parallel with the longest edge of the envelope. For flat-size mail, the address window may be parallel with any edge of the envelope.

e. For registered mail, the opening on a window envelope must be covered as described in S911.

6.2Express Mail and Priority Mail Packaging

Express Mail and Priority Mail packaging provided by the USPS must be used only for Express Mail or Priority Mail, as applicable. Regardless of how the packaging is reconfigured or how markings may be obliterated, any matter mailed in USPS-provided Express Mail or Priority Mail packaging is charged the appropriate Express Mail or Priority Mail rate.

6.3Green Diamond Border Envelope

An envelope or card bearing a green diamond border must be used only for First-Class Mail. Any envelope or card bearing a green diamond border is charged the appropriate First-Class Mail rate, regardless of mail content or of requested class or service. When printed on letter-size mail, the border must not enter the OCR read area or barcode clear zone unless a delivery point barcode appears in the address block as described in C840.

6.4Reusable Mailpiece

A reusable mailpiece is an envelope, self-mailer, or similar mailpiece designed for two-way mailing. The recipient removes part of the original mailpiece or refolds the piece to cover the delivery address of the recipient and reveal the delivery address of the originator (sender) for return. Except for reusable mailpieces that originate as permit imprint mailings, the piece must meet these standards:

a. Basic Design. The piece must be designed and constructed to allow the recipient to reconfigure or modify the piece to remove or obscure the address, POSTNET barcode, postage, and any marking or endorsement that applied to the piece when it was originally mailed so that these elements are not mistaken by USPS employees or mail processing equipment as applying to the returned piece. The instructions on the piece must ensure that the recipient can prepare the piece correctly for remailing. If a reusable mailpiece does not meet the applicable standards, the piece must be reenveloped and new postage affixed before distribution by the originator.

b. Distribution. When the piece is mailed by the originator, the piece must show only one complete delivery address and, if used, the corresponding barcode; the appropriate postage; and any required marking or endorsement. The originator’s address and barcode for returning the piece and any postage, marking, endorsement, and facing identification mark (FIM) provided for that purpose must be obscured so that they are not mistaken by USPS employees or postal mail processing equipment as applying to the originating piece.

c. Return. When the piece is reconfigured for return from the recipient to the originator, the piece must show only one complete delivery address and, if used, the corresponding barcode; the appropriate postage; and any required marking, endorsement, and FIM. If a reusable mailpiece does not meet the applicable standards, the piece must be reenveloped and new postage affixed before return by the recipient.

6.5Reusable Mailpieces That Originate

as Permit Imprint Mailings

As an alternative to the standards in 6.4, reusable mailpieces that originate as permit imprint mailings may meet these standards:

a. Basic Design. The piece must be designed and constructed so that the recipient may reconfigure or modify it to remove or obscure the address that applied to the piece when it was originally mailed. The instructions on the piece must ensure that the recipient can prepare the piece correctly for remailing. If a reusable piece does not meet the applicable standards, the piece must be reenveloped and new postage affixed before distribution by the originator.

b. Distribution. When reusable mailpieces are originally mailed, postage must be paid with permit imprint and a complete address and corresponding barcode must be located in the address block. Reusable pieces must be entered at a postal facility as part of a permit imprint mailing. On mailpieces other than window envelopes, the address block for return of the piece (including the delivery address and a corresponding barcode) and FIM A will be located on the reverse side. If included, prepaid reply postage must be located or obscured so that it is not mistaken by postal mail processing equipment or employees as applying to the originating piece.

c. Return. When the piece is reconfigured for return from the recipient to the originator, only one complete address with a corresponding barcode located in the address block and a FIM must be visible on the piece. If a reusable mailpiece does not meet the applicable standards, the piece must be reenveloped and new postage affixed before return by the recipient.

7.0 Mailing Test Packages

Packaging not meeting the minimum standards described above may be allowed in a “test” status by the originating BMC manager. If the test packaging achieves acceptable performance levels, the mailer may continue to use the packaging. This decision is subject to appeal as detailed in G020. Test status is also available for any provision under the bulk mail system standards in 8.0.

8.0 Bulk Mail System Standards

8.1Books

Books with 24 pages or more, fastened together along one edge between hardback, paperback, or self-covers, and more than 1 inch thick or 1 pound must not be accepted in letter-style nongusseted, flat envelopes. Other envelopes meeting the standards above must be used. Void spaces within multiple book containers must be filled with dunnage or otherwise stabilized to prevent shifting or damage to the contents or container. Shipments of books are packaged according to these weight categories:

a. Up to 5 pounds, closure must be by multiple friction closures, completely clinched staples, heat-sealing, adhesives, tape, or nonmetallic banding. Although shrinkwrap is not acceptable as the only packaging for hardback books exceeding 1 pound or 1 inch thick, it may be used on the exterior of otherwise acceptable containers. Shrinkwrap may be used as the only method of packaging for paperback books up to 3 pounds.

b. From 5 to 10 pounds, closure must be by tape, nonmetallic banding, or adhesives. Reinforced tape or nonmetallic banding is adequate for both closure and reinforcement. Nonmetallic banding must be firmly applied to the point that the straps must be tightened until they depress the carton at the edges.

c. From 10 to 25 pounds, reinforced tape or nonmetallic banding is adequate for closure and reinforcement. Nonmetallic banding must be firmly applied to the point that the straps tighten until they depress the carton at the edges.

d. From 25 to 50 pounds, hardbound books must be packaged in 275-pound test fiberboard boxes and paperback books must be packaged in 200-pound test fiberboard boxes.

e. From 50 to 70 pounds, hardbound books must be packaged in 350-pound test fiberboard boxes and paperback books must be packaged in 275-pound test fiberboard boxes.

8.2High-Density Items

High-density items (see 2.6) weighing from 20 to 45 pounds must be packaged in fiberboard boxes constructed of a minimum 200-pound test board or equivalent wood, metal, or plastic containers. Plastic, metal, and similar hard containers must be packaged, treated, or otherwise prepared so that their coefficient of friction or ability to slide on a smooth, hard surface is similar to that of a domestic-class fiberboard box of the same approximate size and weight. Closure must be done by staples, heat-shrinking, adhesives, or tape. Boxes without inner packing or containing loose material must be reinforced or banded with reinforced paper or plastic tape, pressure-sensitive filament tape, or firmly applied nonmetallic banding. Internal blocking and bracing, including the use of interior containers, cut forms, partitions, dunnage, and liners, must be used as required so that packages are capable of maintaining their integrity without damage to the contents if dropped once on one of their smallest sides on a solid surface from a height of 3 feet. These items from 45 to 70 pounds must be similarly packaged, closed, and reinforced, except that exterior containers must be a minimum of 275-pound test fiberboard or equivalent.

8.3Soft Goods

Boxes containing soft goods (e.g., textiles, clothing, sheets, blankets, pillows and pillowcases, draperies, cloth, and any wearing apparel) weighing up to 5 pounds must be filled to capacity. Soft goods between the weight range of 5 to 20 pounds must be packaged in material with a minimum 70-pound outer ply basis weight. Closure of bags must be by completely clinched staples, heat-sealing, adhesives, sewing, or tape. Improperly clinched staples must be removed. Shrinkwrapping is not acceptable as the only packaging. Fiberboard containers must be made of at least 200-pound test board for soft goods weighing from 20 to 45 pounds and at least 275-pound test board for soft goods weighing from 45 to 70 pounds.

8.4Sound Recordings

Shipments of recordings (e.g., records and cassette tapes in paper sleeves, paperboard, or chipboard shells) weighing up to 10 pounds must be packed in 70-pound basis weight envelopes for weights up to 3 pounds, or outer corrugated, fiberboard containers for weights up to 10 pounds. When shipments weigh from 20 to 40 pounds, multiple shell containers must be packaged in 175-pound test fiberboard containers or equivalent and closed and reinforced by adhesives, kraft paper tape, equivalent plastic tape, or staples. When shipments weigh from 40 to 65 pounds, multiple shell containers up to 65 pounds must be packaged in 200-pound test fiberboard containers or equivalent and closed and reinforced as described for 20- to 40-pound containers, except that containers must be reinforced about every 8 inches around the package. Shipments weighing more than 65 pounds must be packaged in 275-pound test fiberboard containers or equivalent.

8.5Magnetic Tapes

Shipments of multiple magnetic tapes and cartridges up to 5 pounds must be packed in outer fiberboard containers or chipboard containers (minimum 0.022 mil). Closure must be by multiple friction closures, completely clinched staples, heat-shrinking or adhesives, or by tape. Paper tape must be a minimum of 60-pound basis weight kraft. Shrinkwrapping is acceptable on the exterior of otherwise acceptable boxes of multiple tape shipments. Standards for shipments weighing from 5 to 20 pounds are similar, except that closure must be only by the use of adhesives, tape, or staples. Standards are also similar for shipments weighing from 20 to 40 pounds, except that the contents must be placed in 175-pound test containers that are banded or reinforced at two points with reinforced paper or plastic tape, pressure-sensitive filament tape, or firmly applied nonmetallic banding. Shipments from 40 to 65 pounds must be similarly packaged, except that fiberboard containers of at least 200-pound test board or equivalent must be used. Shipments weighing more than 65 pounds must be packaged in 275-pound test fiberboard containers or equivalent.

9.0 Marking

9.1Method

The mailer must mark the package using material that is not readily water soluble or easily smeared or rubbed off. The marking must be readable at a distance of 30 inches. Marking methods or surfaces must permit application and retention of adhesive stamps, postage meter impressions, and postal endorsements made with hand stamp, ballpoint pen, or Number 2 pencil. Any address label or envelope must be firmly affixed to the mailing container, with no more than an 1/8-inch separation between the ends of the label or envelope and the container.

9.2Handling, Content, and Special Service

Certain markings may be used to identify handling, content, and special service. Unauthorized markings not designating rate, class, address, handling, content, or special service are not permitted. Extraneous information, which can be confused with ZIP Codes, may not be placed next to or directly under the last line of the delivery address. Any obsolete marking on a container to be reused for mailing must be obliterated. The following markings must be placed in an area below the postage and above the addressee’s name in the delivery address and to the right of the return address:

a. Handling markings such as “Fragile” must be applied only to packages containing delicate items such as glass and electrical appliances. Markings such as “Do Not Bend” must be used only when the content is protected with stiffeners.

b. Content markings such as “Perishable” must be applied to any package containing items or substances that can degrade or decompose rapidly such as meat, produce, plants, or certain chemical and hazardous materials samples. Restricted and hazardous articles must be marked and labeled under applicable standards. A container improperly identified by content is not acceptable for mailing (e.g., a box marked “Art Supplies” that contains flammable liquid or a box marked “Bleach” that contains clothing).

c. Special service markings such as “Return Receipt Requested” must use the wording or label required by the applicable special service standards.

10.0 Nonmailable Matter

10.1Scope

Certain potentially undesirable, harmful, or dangerous matter is nonmailable by statute or regulation. The standards for nonmailable articles and substances and the special conditions under which certain of these articles and substances may be mailed are in C020. The standards in C030 apply to nonmailable matter in written, printed, or graphic form and contain the rules on advising mailers of matter covered in C020 and C030. The standards in C030 apply to the military postal system, its employees, and undelivered mail that is or has been in the official custody of this system and its employees. References to Inspection Service apply to the Postal Inspection Service and authorized employees, not military investigative services.

10.2Other Nonmailable Matter

Matter is also nonmailable when it cannot be forwarded to its destination because of illegible, incorrect, or insufficient address, or when it does not meet USPS standards for mail preparation, classification, postage rates, size, or weight.

10.3Mailer’s Responsibility

It is the mailer’s responsibility to refrain from depositing nonmailable matter in the mail. The mailer must comply with applicable postal laws and regulations governing mailability and preparation for mailing, as well as nonpostal laws and regulations on the possession, treatment, transmission, or transfer of particular matter. Information about USPS standards is available from postmasters, business mail entry managers, and RCSC managers (see G042).

10.4Unauthorized Decisions

Postmasters are not authorized to decide whether written, printed, or graphic matter is nonmailable based on its content or to deny entry to such matter or exclude it from the mail.

10.5Refusal

Written, printed, or graphic matter not properly prepared for mailing can be refused.

DMM Issue 58 (8-10-03)