|

|

C800 Automation-Compatible Mail

C820 Flats

Summary

C820 describes the physical criteria for automation-compatible flats, including the use of tabs, wafer seals, tape, outside labels and stickers on flats, and the uniformity of exterior surface. It also lists polywrap specifications.

1.0 Basic Standards

[10-2-03] Flat-size mail claimed at automation rates must meet the applicable standards in 1.0 through 8.0 and the general and specific mailability and eligibility standards for the class of mail and the rate claimed. The mail may qualify for automation rates either under the dimensions and characteristics for automated flat sorting machine (AFSM) 100 processing in 2.0 or under the dimensions and characteristics for upgraded flat sorting machine (UFSM) 1000 processing in 3.0, except for Bound Printed Matter (BPM), which can qualify only under AFSM 100 criteria. Additional standards apply as follows:

a. If a flat-size mailpiece meets all AFSM 100 criteria except for the turning ability or deflection standards under 2.5, the piece may be claimed at automation rates if all UFSM 1000 criteria are met.

b. If polywrap film is used, the film and preparation of the mailpiece must meet the applicable standards in 4.0.

2.0 Criteria for AFSM 100 Flats

2.1Determining Length and Height

The length and height of an automation-compatible flat-size mailpiece is not determined by the orientation of the address, but by the preparation of the piece:

a. For a piece prepared as a single sheet or in an envelope, full-length wrapper, or full-length sleeve, the length is the longest dimension. The height is the dimension perpendicular to the length.

b. For a piece prepared with a bound, folded, or closed edge (e.g., a catalog, a newspaper or tabloid, a folded envelope), the length is the dimension parallel to the bound, folded, or closed edge. The height is the dimension perpendicular to the length. If the piece is folded more than once or is bound and then folded, the length is the dimension parallel to the final fold.

2.2Final Fold

An AFSM 100 flat-size piece with a final fold must be designed so that the address is in view when the final folded edge is at the bottom of the piece and any intermediate bound or folded edge is to the right.

2.3Shape and Size

Each flat-size piece must be rectangular and:

a. For height, no more than 12 inches and no less than 5 inches high.

b. For length, no more than 15 inches and no less than 6 inches long.

c. For thickness, no more than 0.75 inch and no less than 0.009 inch thick.

2.4Maximum Weight

Maximum weight limits are as follows:

a. For First-Class Mail, 13 ounces.

b. For Periodicals, 20 ounces.

c. For Standard Mail, less than 16 ounces.

d. For Bound Printed Matter, 20 ounces.

2.5Turning Ability and Deflection

The piece must meet the following standards for turning ability and deflection:

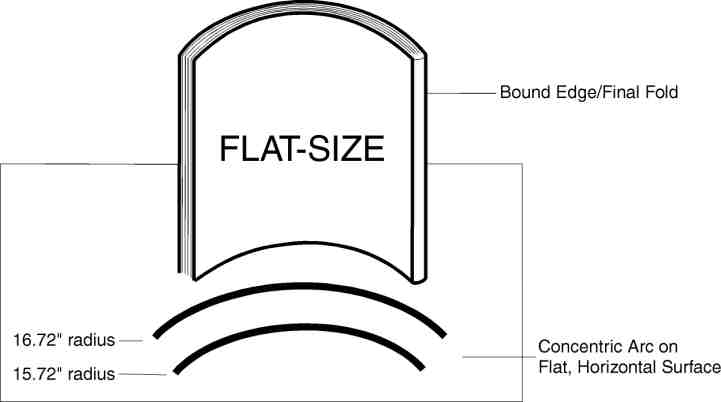

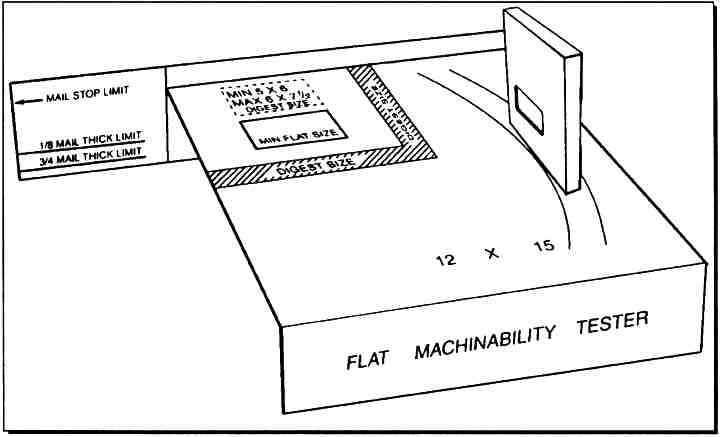

a. Turning Ability. The mailpiece must fit between two concentric arcs drawn on a horizontal flat surface, one with a radius of 15.72 inches and the other with a radius of 16.72 inches, in one of the following ways:

(1) The piece must be flexible enough to bend between the two arcs when positioned vertically, with (if applicable) the bound, folded, or final folded edge perpendicular to the surface where the arcs are drawn.

(2) If rigid (constructed of or containing inflexible materials), the piece must be small enough to allow its longest edge to be placed between the two arcs without touching the lines of the arcs.

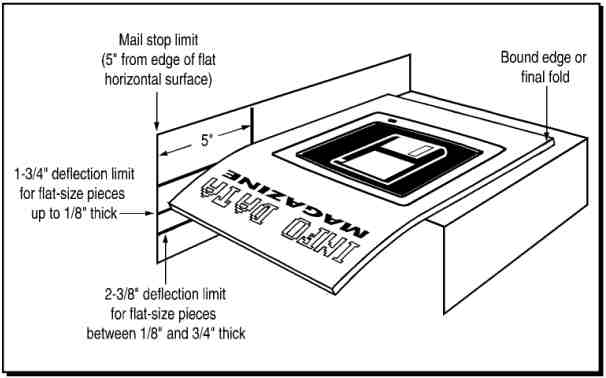

b. Deflection. A flat-size mailpiece meeting the AFSM 100 dimensions must be rigid enough so that, when placed flat on a surface to extend unsupported 5 inches off that surface, no part of the edge of the piece that is opposite the bound, folded, or final folded edge (as applicable) deflects more than 1-3/4 inches (if the piece is less than 1/8 inch thick) or more than 2-3/8 inches (if the piece is from 1/8 to 3/4 inch thick).

c. Test Device. Testing for compliance with the above standards must be done with a flat mail machinability tester constructed to USPS specification USPS-STD-28 and following the instructions for use of that device. Information about obtaining or using the tester is available from the local USPS area or district marketing office or local postmaster.

Exhibit 2.5a(1)Turning Ability Flexible Flat

Exhibit 2.5a(2)Turning Ability

Rigid Flat

Exhibit 2.5bDeflection

Flat-Size Mail

3.0 [10-2-03] Criteria for UFSM 1000 Flats

3.1Determining Length and Height

The length and height of an automation-compatible flat-size mailpiece eligible for FSM processing is not determined by the orientation of the address. It is determined by the following:

a. For a piece prepared as a single sheet or in an envelope, full-length wrapper, or full-length sleeve, the length is the longest dimension. The height is the dimension perpendicular to the length.

b. For a piece that has a bound or folded edge (e.g., a newspaper, tabloid, or catalog), the length is the dimension parallel to the bound or folded edge. The height is the dimension perpendicular to the length. If the piece is folded more than once or bound and then folded, the length of the mailpiece is based on the final fold.

3.2Address Placement and Folded Pieces

The following requirements apply to folded pieces:

a. A flat-size piece with a final fold must be designed so that the address is in view when the final folded edge is to the right and any intermediate bound or folded edge is at the bottom of the piece.

b. Unbound flat-size pieces must be at least double-folded.

3.3Shape and Size

Pieces must meet the following requirements:

a. Height: no more than 12 inches or less than 4 inches.

b. Length: no more than 15-3/4 inches or less than 4 inches.

c. Minimum thickness:

(1) For pieces at least 5 inches long: 0.009 inch.

(2) For pieces at least 4 inches long but less than 5 inches long: greater than 0.25 inch.

d. Maximum thickness:

(1) For pieces 13 inches long or less: 1.25 inches.

(2) For pieces longer than 13 inches up to and including 15-3/4 inches: 7/8 inch.

3.4Maximum Weight

Maximum weight limits are as follows:

a. For First-Class Mail, 13 ounces.

b. For Periodicals, 6 pounds.

c. For Standard Mail, less than 16 ounces.

4.0 Polywrap Coverings

4.1Polywrap Films

[10-2-03] If polywrap film is used to enclose flat-size mailpieces claimed at automation rates, the pieces must meet the applicable additional standards in 4.0. Film approved for use under 4.5 must meet the specifications in Exhibit 4.1 as follows:

a. For mailpieces meeting all the dimensions, turning ability, and deflection characteristics for AFSM 100 criteria under 2.0, the film must meet all eight properties in this exhibit. If the address label is affixed to the outside of the polywrap, the haze property (property 2) is not required.

b. For mailpieces not meeting all the dimensions and characteristics of the AFSM 100 criteria but meeting all the criteria for the UFSM 1000 under 3.0, the film must meet, at a minimum, only the haze property (property 2) in this exhibit. If the address label is affixed to the outside of the polywrap, the haze property is not required.

Exhibit 4.1AFSM 100 Polywrap

Specifications

[10-2-03] Polywrapped AFSM 100 flats (see 2.0) must be prepared with polywrap that meets all eight properties in this exhibit. Polywrapped UFSM 1000 flats (see 3.0) must be prepared with polywrap that meets, at a minimum, only property 2 (haze).

.

| Property | Requirement | Test Method | Comment |

|---|---|---|---|

| 1. Kinetic Coefficient of Friction, MD |

Stainless steel finish must be in accordance with ASTM A 480/A 480M. | ||

| a. Film on Stainless Steel with No. 8 (Mirror) Finish |

<0.28 | ASTM D1894 | |

| b. Film on Film | 0.20 to 0.40 | ASTM D1894 | |

| 2. Haze | <70 | ASTM D1003 | Affixing address labels to outside of polywrap is an alternative to meeting this requirement. |

| 3. Secant Modulus, 1% elongation | |||

| a. TD, psi | >50,000 | ASTM D882 | |

| b. MD, psi | >40,000 | ASTM D882 | |

| 4. Tensile Strength | |||

| a. TD, psi | >2,000 | ASTM D882 | |

| b. MD, psi | >3,000 | ASTM D882 | |

| 5. Density, g/cc | 0.900 to 0.950 | ASTM D1505 | |

| 6. Nominal Gauge, in | >0.001 | ASTM D374 | |

| 7. Static Charge, kV | <2.0 | ASTM D4470 | Antistatic additives can regulate this charge. |

| 8. Blocking, g | <15 | ASTM D3354-96 |

4.2Wrap Direction and Seam Placement

[10-2-03] Wrap direction, seam direction, and seam placement must follow these standards:

a. Wrap direction and seam direction:

(1) For an AFSM 100 mailpiece, the wrap direction must be around the longer axis of the mailpiece, with the seam parallel to that axis. The longer axis is always parallel to the longer edge (the length) of the mailpiece.

(2) For a UFSM 1000 mailpiece, the wrap direction may be around either the longer axis or the shorter axis of the mailpiece, with the seam parallel to that axis. The longer axis is always parallel to the longer edge (the length) of the mailpiece, and the shorter axis is always parallel to the shorter edge (the height) of the mailpiece.

b. For either an AFSM 100 or a UFSM 1000 mailpiece, the preferred seam placement is on the nonaddressed side of the mailpiece. If the seam is placed on the addressed side, the seam must not cover any part of the delivery address and barcode, postage area, or any required markings or endorsements. Regardless of seam placement, the polywrap over the address area must be a smooth surface to avoid interference with address and barcode readability.

4.3Overhang

[10-2-03] [9-4-03] For purposes only of the polywrap standards for overhang (selvage) in 4.0, the edge of the mailpiece designated as top must be one of the two physically longer edges of the piece, regardless of address orientation and whether bound or unbound. Any polywrap overhang (selvage) around the four edges of the mailpiece (top, bottom, and left and right sides) must meet these standards:

a. For an AFSM 100 mailpiece:

(1) When the mailpiece contents are totally positioned at the bottom of the polywrap, the overhang must not be more than 0.5 inch at the top of the mailpiece.

(2) When the mailpiece contents are totally positioned to the left or to the right side of the polywrap, the overhang must not be more than 1.5 inches on the opposite side.

(3) The polywrap covering must not be so tight that it bends the mailpiece.

b. For a UFSM 1000 mailpiece:

(1) When the mailpiece contents are totally positioned at the bottom of the polywrap, the overhang must not be more than 1.5 inches at the top of the mailpiece.

(2) When the mailpiece contents are totally positioned to the left or to the right side of the polywrap, the overhang must not be more than 1.5 inches on the opposite side.

(3) The polywrap covering must not be so tight that it bends the mailpiece.

4.4Mailpiece Identification

[10-2-03] Polywrapped flat-size mailpieces claimed at automation rates must be endorsed to show that the polywrap meets USPS approval as automation-compatible. This requirement is met by printing “USPS AFSM 100 Approved Polywrap” or “USPS 100 Approved Poly” or “USPS UFSM 1000 Approved Polywrap” or “USPS 1000 Approved Poly,” as applicable, directly on the address side of the pieces, preferably below the postage area or in another visible location. Alternatively, the polywrap marking may be printed directly onto the polywrap material. The polywrap marking must not interfere with delivery address or barcode recognition.

4.5Polywrap Certification

The USPS polywrap certification program requires plastic manufacturers to provide to a producer of polywrapped flat-size mailpieces a certificate of conformance from the manufacturer stating that the polywrap physical properties meet or exceed the minimum requirements specified in Exhibit 4.1. The certification program applies only to polywrap used for AFSM 100 mailpieces. A list of USPS-approved polywrap products is maintained on the USPS Web site http://ribbs.usps.gov. The first time that a specific polywrap product is to be used for an automation rate mailing of flat-size mailpieces and that product is not listed on the USPS Web site, these steps must occur:

a. The producer of the polywrapped pieces provides a USPS mailpiece design analyst (MDA) with the manufacturer’s certificate of conformance verifying that the polywrap film meets the specifications in Exhibit 4.1 for AFSM 100 mailpieces.

b. The MDA reviews the manufacturer’s certificate of conformance to confirm that the requirements listed on the certificate for the polywrap film meet the eight properties in Exhibit 4.1 for AFSM 100 mailpieces. The reviewing MDA provides written confirmation to the producer of the polywrapped pieces and sends a copy to the appropriate business mail entry unit or detached mail unit and a copy to Mailing Standards (see G043 for address).

5.0 Prohibitions

5.1Protrusions

Clasps, strings, buttons, or like materials, or other protrusions that impede or damage mail processing equipment are prohibited.

5.2Staples

Staples must not be substituted for tabs or wafer seals on pieces in automation rate mailings. As a binding method, staples may be placed in the fold or spine of a magazine or booklet-type or similar mailpiece if parallel with the bound edge, tightly and securely inserted, and not protruding to damage or interfere with mail processing equipment.

6.0 Tabs, Wafer Seals, Tape, and Glue

6.1General

Although not required, mailpieces may be prepared with tabs, wafer seals, cellophane tape, or permanent glue (continuous or spot) if these sealing devices do not interfere with the recognition of the barcode, rate marking, postage information, and delivery and return addresses. Cellophane tape may not be placed over the barcode or where any part of the barcode will be printed. Tabs or seals placed in the area on which any part of the barcode is printed must contain a paper face meeting the standards for background reflectance. Tabs, wafer seals, and tape must have a peel adhesion (shear strength) value of at least 15 ounces/inch at a speed of 12 inches/minute after application to a stainless steel plate; the test is to be conducted 10 minutes after the material is applied to the plate.

6.2Short Covers

Flats may be prepared with a cover page or protective cover that is more than 3/4 inch from each edge if the cover page is secured with at least two tabs, wafer seals, or glue spots placed within 1 inch of the top and bottom edges of the cover page or protective cover.

7.0 Uniformity AND EXTERIOR FORMAT

7.1General Requirements

A flat-size mailpiece prepared and claimed at automation rates must be uniformly thick. Each flat-size mailpiece must have a smooth and regular shape and be free of creases, folds, tears, or other irregularities not compatible with automation equipment. The exterior surface must not have protuberances caused by prohibited closures; attachments (except as provided below); irregularly shaped or distributed contents; or untrimmed excess material from the envelope, wrapper, or sleeve.

7.2Outside Attachment

An attachment to a flat-size mailpiece must be a single sheet, the same size as the cover. The attachment must be permanently, securely, and uniformly affixed to the front or back cover along a bound, folded, or otherwise closed edge. Pieces claimed at a Periodicals rate may bear attachments only if permitted by the applicable standards.

7.3Contents

The contents of a flat-size mailpiece must remain uniformly thick so that the dimensions of the envelope, wrapper, or sleeve remain constant. If the contents are of irregular thickness or significantly smaller than the envelope, wrapper, or sleeve, those contents must be secured in place to prevent shifting within the wrapping during processing and surrounded with loose packing material or padding to ensure that the mailpiece remains uniformly thick.

7.4Booklet-Type Piece or Magazine

The contents of flat-size mailpieces prepared in sleeves or other wrappers must be sufficiently secure in the sleeve or wrapper to stay in place during processing. If material bearing the delivery address or barcode for the mailpiece is enclosed in a partial wrapper, that wrapper must be sufficiently secure to prevent the contents from shifting and obscuring the delivery address or barcode.

8.0 Outside Labels and Stickers

8.1Use

Permanent labels and stickers (i.e., those designed not to be removed or relocated) must be affixed directly to the outside of the mailpiece with permanent adhesive. A mailer may provide recipients with relocatable labels to place on the outside of response pieces sent back to the mailer. On pieces mailed at Periodicals rates, labels and stickers may be used only if permitted by the applicable standards.

8.2Pressure-Sensitive Label

Any pressure-sensitive label or sticker affixed directly to a mailpiece before mailing must have a minimum peel adhesion to stainless steel of 8 ounces/inch. This standard does not apply to pressure-sensitive labels provided by the USPS to label bundles to sortation levels.

8.3“Sandwich” Label

A face stock/liner label (“sandwich” label) is a two-part unit with a face stock (top label) attached to a liner (bottom label) affixed to the mailpiece. The face stock must have a peel adhesion value of at least 2 ounces/inch with respect to the liner label and at least 8 ounces/inch when reapplied to stainless steel.

DMM Issue 58 Updated 12-9-04