|

|

M000 General Preparation Standards

M030 Containers

M032 Barcoded Labels

Summary

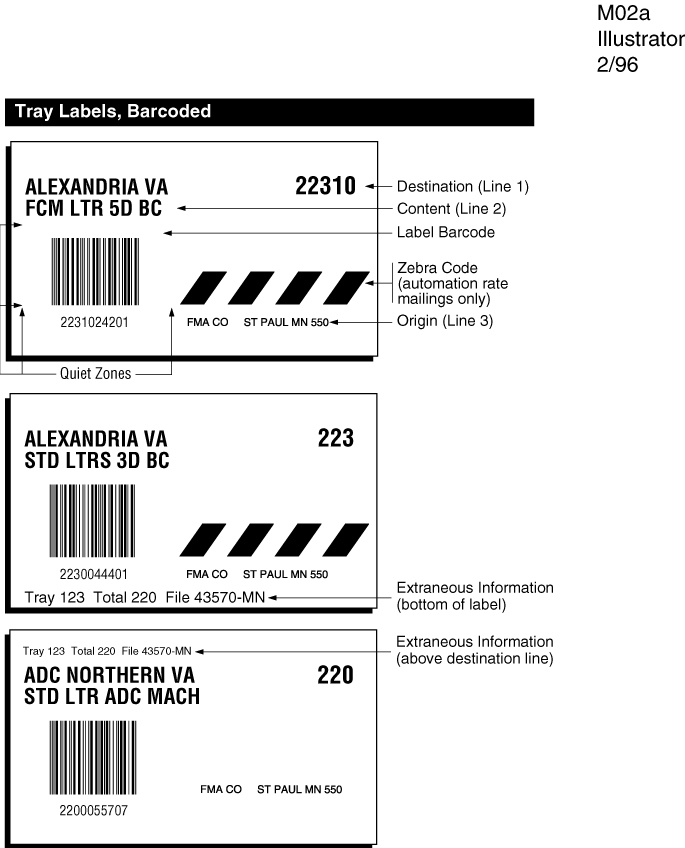

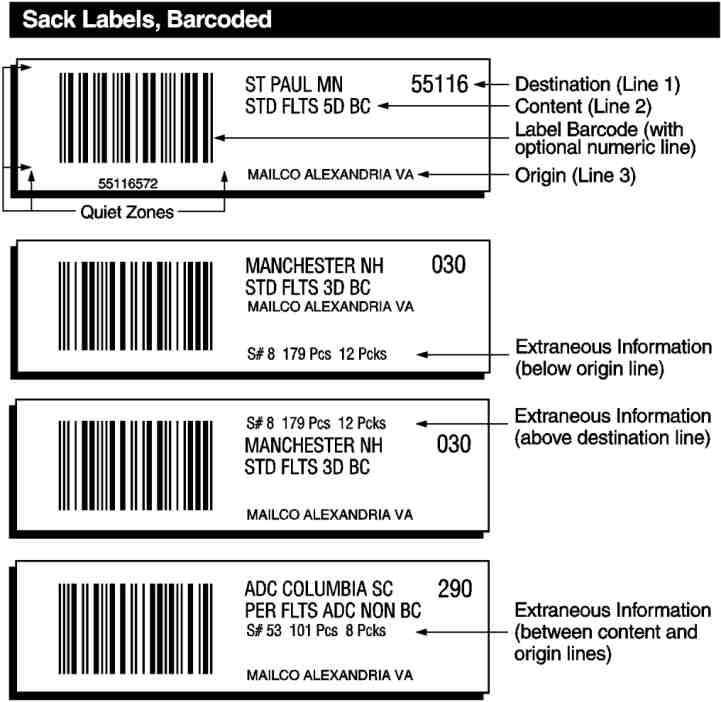

M032 describes the basic standards for barcoded labels on trays and sacks including the destination line (Line 1), content line (Line 2), and origin line (Line 3) for tray and sack labels. It lists the 3-digit content identifier number (CIN) that must be used. It also covers the specifications for barcoded tray and sack labels.

1.0 Basic Standards—Tray and Sack Labels

1.1Use

Exhibit 1.1 shows the types of mail requiring barcoded tray or sack labels. Barcoded labels must meet these general standards:

a. Barcoded tray labels and sack labels must not be interchanged. Tray labels must be used only for trays, and sack labels must be used only for sacks.

b. Mailer-produced barcoded labels must meet the standards in M032.

c. All information on barcoded labels must be machine-printed. Alterations to preprinted barcoded labels (e.g., handwritten changes) may not be made.

d. Barcoded labels must be inserted completely into the label holder on the tray or sack to prevent their loss during transport and processing.

Exhibit 1.1Required Barcoded Container Labels

| Class of Mail | Rate or Type | Processing Category |

| First-Class Mail | Automation rate | Letter-size, flat-size |

| Cobundled and cotrayed under M900 | Flat-size | |

| Periodicals | Automation rate | Letter-size, flat-size |

| Cobundled and cosacked under M900 | Flat-size | |

| Standard Mail | Automation rate | Letter-size, flat-size |

| Enhanced Carrier Route high-density and saturation letter rates | Letter-size (barcoded labels not required for letter-size pieces at nonletter rates) | |

| Cobundled and cosacked under M900 | Flat-size | |

| Automation, Presorted, and Enhanced Carrier Route in letter trays under M033 | Flat-size | |

| Automation and Presorted in letter trays cotrayed under M910 using M033 option | Flat-size | |

| Bound Printed Matter | Barcoded | Flat-size |

1.2Line 1 (Destination Line)

[10-30-03] The destination line must meet these standards:

a. Placement. The destination line must be the top line of the label, placed in the position shown in Exhibit 1.2a or Exhibit 1.2b (above the barcode on tray labels and to the right of the barcode on sack labels). An exception is that one line of extraneous information may appear above the destination line on tray and sack labels as provided in 2.2f and 3.2f. The destination line must be completely visible when placed in the label holder. This visibility is ensured if the destination line is no less than 1/8 (0.125) inch below the top of the label when the label is cut and prepared.

|

|

|

|

b. Information. The destination line must contain only the information required by the applicable standards for the class, processing category, sortation level of the tray or sack, and the rates claimed. This information is contained in module L labeling lists for all sortation and rate levels except trays and sacks to carrier route, 5-digit carrier routes, merged 5-digit, and 5-digit destinations, and except for automation letter trays to 5-digit scheme destinations. For the destination line of carrier route, 5-digit carrier routes, merged 5-digit, and 5-digit trays and sacks, the city, two-letter state abbreviation, and 5-digit ZIP Code of the destination 5-digit ZIP Code area must be shown. For 5-digit scheme trays, the city, two-letter state abbreviation, and ZIP Code for the destination scheme must be obtained from the City State Product. The destination line may contain abbreviated city and state information if such abbreviations are those in the City State Product or in Publication 65, National Five-Digit ZIP Code and Post Office Directory.

c. Overseas Military Mail. On 5-digit sacks and trays for overseas military destinations, Line 1 shows, from left to right, “APO” or “FPO,” followed by “AE” (for ZIP Codes within the ZIP Code prefix range 090-098), “AA” (for ZIP Codes within the 3-digit ZIP Code prefix 340), or “AP” (for ZIP Codes within the ZIP Code prefix range 962-966), followed by the destination 5-digit ZIP Code of the mail in the sack or tray.

1.3Line 2 (Content Line)

[10-30-03] The content line must meet these standards:

a. General. The content line must appear directly below the destination line as shown in Exhibit 1.2a or Exhibit 1.2b. This line must show the class, processing category, and the sortation level of the tray or sack as required by the applicable standards for the mailing in module M. The appropriate content identifier number (CIN) in Exhibit 1.3 that corresponds to that content line must be used in the barcode.

b. Periodicals. Except as provided in M045.8.0 for copalletized mailings and in M230.2.0 for combined mailings, Periodicals publications must use one of the following for Line 2 class information:

(1) “PER.”

(2) “NEWS” if published weekly or more often or if authorized newspaper treatment as of March 1, 1984.

c. Additional Information. For 3-digit scheme trays as specified by the labeling list, the content line for some destinations must be followed by the letter “A,” “B,” or “C,” which is not required to be right-justified. For carrier route trays and sacks, the content information must be followed by a one-letter carrier route type description followed by a space and a 3-digit route number for the route to which the tray is destined.

1.4Line 3 (Origin Line)

The origin line must appear below the content line in a location appropriate for a tray or sack as shown in Exhibit 1.2a or Exhibit 1.2b. This line must show the city and state of the entry post office or the mailer’s name and the city and state of the mailer’s location. It is recommended that the mailer’s name also appear with the city and state of the entry post office. The origin line may contain abbreviated city and state information if such abbreviations are those in the USPS City State Product or in Publication 65, National Five-Digit ZIP Code and Post Office Directory. A mailer code assigned by the USPS or such words as “Mailer,” “From” (or “FR”), or “Entered at” may appear before the required information on this line.

2.0 Additional Standards—Barcoded Tray Labels

2.1Paper Stock, Size, and Color

A barcoded tray label must meet these specifications:

a. Color: white or manila for First-Class Mail and Standard Mail; pink for Periodicals.

b. Reflectance: minimum reflectance requirements in 2.4i.

c. Perforations: perforations are not permitted through the barcode and barcode quiet zone on labels.

d. Weight: minimum 70-pound paper stock (500 sheets, 24 by 36 inches).

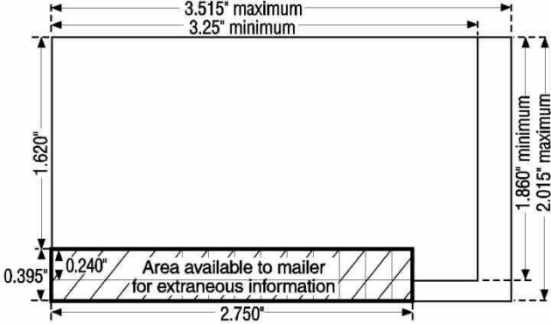

e. Height: 1.860 inches minimum; 2.015 inches maximum.

f. Length: 3.250 inches minimum; 3.515 inches maximum.

g. Thickness: 0.005 inch minimum.

2.2Printed Human-Readable Lines

The printed human-readable text lines must meet these specifications:

a. General. The human-readable lines must be printed in uppercase letters, with no run-on letters or numerals. The letters and numerals in the destination, content, and origin lines must be easy to read. The character spacing can be proportional with respect to the type font used.

b. Destination Line (Line 1). The printed destination line must have a minimum character height of 0.120 inch and a maximum character density of 17 characters per inch. The corresponding ZIP Code must have a minimum character height of 0.190 inch and a maximum character density of 10 characters per inch. The destination line must accommodate at least 21 characters for the destination city and state and any required prefixes, and 5 characters for the ZIP Code. Only the correct 3-digit ZIP Code prefix is to be printed when the required labeling for a tray includes only a 3-digit ZIP Code prefix for Line 1 (i.e., trailing zeros are not permitted).

c. Content Line (Line 2). The printed content line must have a minimum character height of 0.120 inch. The content line must accommodate at least 21 characters and have an effective font density of no greater than 17 characters per inch.

d. Origin Line (Line 3). The printed origin line must have a maximum character height of 0.085 inch and must accommodate at least 21 characters.

e. Barcode Numeric Line. The barcode numeric line must consist of a numeric representation of the information contained in the barcode as required by 2.4b (5-digit ZIP Code, CIN, processing code). The printed numeric barcode line must have a maximum character height of 0.085 inch, must accommodate 10 characters, and must be placed below the barcode and lower barcode quiet zone as shown in Exhibit 1.2a.

f. Extraneous Information Lines. Extraneous information may be printed only at the top of the label and/or at the bottom of the label. The preferred location is the bottom of the label. If placed at the bottom of the label, the information must appear only in a rectangular area that begins 1.620 inches from the top of the label and extends to the bottom of the label. Within this lower area, the information may extend 2.75 inches to the right from the left edge of the label. See Exhibit 2.2f. Extraneous information at the bottom of the label must appear below the barcode numeric and origin lines. There are no font restrictions for information printed in this area at the bottom of the label with one exception: if information in this area resembles a day of the week or a USPS air stop code it must be in 10-point or smaller type. Extraneous information printed at the top of the label must have a maximum character height of 0.083 inch. Barcodes for a mailer’s internal use may not be placed in extraneous information areas or anywhere else on the label, unless approved on a case-by-case test basis by USPS Engineering (see G043 for address).

2.3Zebra Code

The zebra code is a series of diagonal or vertical marks to the right of the barcode that serves as a visual indication that a tray contains automation rate mail. The diagonal or vertical marks must each be from 0.25 to 0.375 inch high, and from 0.125 to 0.25 inch wide, separated by blank spaces equal in size to the diagonal or vertical marks. The zebra code is required on tray labels in automation rate mailings; it is not required on cotrayed automation and Presorted rate mailings. The zebra code must not appear on tray labels for nonautomation rate mail.

Exhibit 2.2fExtraneous Information Area at Bottom

of Label

2.4Barcode

The label barcode must meet these specifications:

a. Type of Barcode. The barcode must be an interleaved 2-of-5 code according to the Automatic Identification Manufacturers’ Uniform Symbology Specification (AIM/USS-I 2/5) with the exceptions noted below.

b. Information. The barcode must represent three numeric elements:

(1) The 5-digit ZIP Code destination of the tray. For a 3-digit tray destination, the 3-digit ZIP Code prefix is followed by two zeros.

(2) The applicable 3-digit content identifier number (CIN) for the tray as shown in Exhibit 1.3.

(3) The applicable 2-digit USPS processing code:

(a) Code “01” is used for all automation rate and machinable

letter-size pieces, for First-Class Mail automation rate flat-size pieces,

and for First-Class Mail cotrayed automation rate and Presorted rate

flat-size pieces. Code “01” is used also for certain Standard

Mail flat-size pieces prepared in letter trays under M033: Standard Mail automation rate flat-size

pieces and Standard Mail cotrayed automation rate and Presorted rate

flat-size pieces. (b) Code “07” is used for all other mail

(e.g., manual and nonmachinable letter-size pieces). Code “07”

is also used for certain Standard Mail flat-size pieces prepared in

letter trays under M033: Enhanced Carrier Route Standard

Mail nonautomation rate and Standard Mail Presorted rate.

c. Placement. The barcode must be on the left side of the tray label, below the destination and content lines. The top of the barcode must be not less than 0.6 inch from the top of the label. The bottom of the barcode must be no more than 1.5 inches from the top of the label. The barcode must not extend more than 2.0 inches to the right from the left edge of the label.

d. Quiet Zones. Two quiet zones (clear areas) must be maintained, one to the left and one to the right of the barcode, each measuring at least 10 times the X dimension (see 2.4f) and extending the full height of the barcode. Two additional quiet zones must be maintained, one above and one below the barcode for its full width, each measuring at least 0.070 inch. The quiet zones must meet the space reflectance specification in 2.4i.

e. Height. The height of the barcode must be from 0.65 to 0.75 inch.

f. X Dimension. The width of the narrow bar element and narrow space element is defined as the X dimension. It must be selected as a single dimension and it must be uniform within the barcode. The minimum X dimension or narrow element width is 0.012 inch and the maximum is 0.016 inch. The optimum X dimension or narrow bar/space width is 0.015 inch.

g. Wide-to-Narrow Bar Ratio. The wide-to-narrow ratio for bars and spaces within the barcode must be between 3 to 1 and 2.3 to 1 and uniform within the barcode. The optimum ratio is 3 to 1.

h. Printing Tolerances. The maximum irregularity in the edge straightness of any bar element is 0.3 times the X dimension. The printing tolerance for any (narrow or wide) bar or space is +0.004 inch and is not cumulative. Example 1: If an X dimension of 0.015 inch is selected, each individual narrow bar or narrow space element on the printing of the barcode must not be less than 0.011 inch or more than 0.019 inch. Example 2: If the wide bar/space dimension of 0.045 inch is selected, each individual wide bar or space must not be less than 0.041 inch or more than 0.049 inch.

i. Reflectance. When measured at 633 nanometers, bar reflectance must be less than 30% and space reflectance must be more than 40%. The bar-to-space reflectance difference must be more than 40%.

3.0 Additional Standards—Barcoded Sack Labels

3.1Paper Stock, Size, and Color

A barcoded sack label must meet these specifications:

a. Color: white or manila for First-Class Mail and Standard Mail and Package Services; pink for Periodicals.

b. Reflectance: minimum reflectance requirements in 3.3i.

c. Weight: minimum 70-pound paper stock (500 sheets, 24 by 36 inches).

d. Height: 0.937 inch minimum; 0.980 inch maximum.

e. Length: 3.250 inches minimum; 3.375 inches maximum.

3.2Printed Human-Readable Lines

The printed human-readable text lines must meet these specifications:

a. General. The human-readable lines must be printed in uppercase letters, with no run-on letters or numerals. The letters and numerals in the destination, content, and origin lines must be easy to read. The character spacing can be proportional with respect to the type font used, and should not exceed 17 characters per inch. When the information cannot be shortened by acceptable postal abbreviations, it may be printed in a compressed font. The information must appear to the right of the right barcode quiet zone.

b. Destination Line (Line 1). The printed destination line must have a minimum character height of 0.083 inch. The corresponding ZIP Code must have a minimum character height of 0.111 inch. The destination line must accommodate at least 22 characters.

c. Content Line (Line 2). The printed content line must have a minimum character height of 0.083 inch. The content line must accommodate at least 21 characters.

d. Origin Line (Line 3). The printed origin line must have a minimum character height of 0.083 inch.

e. Barcode Numeric Line. A barcode numeric line is optional. If used, the numeric line must consist of a numeric representation of the eight digits of information contained in the barcode as required by 3.3b (5-digit ZIP Code and CIN). The printed numeric barcode line must have a maximum character height of 0.085 inch. It must be placed a minimum of 0.070 inch below the barcode (see Exhibit 1.2b).

f. Extraneous Information Lines. Extraneous information may be printed only to the right of the right quiet zone if it does not interfere with scanning and sorting by automated equipment. Extraneous information may be placed (1) below the origin line; (2) above the destination line; or (3) either between the content and origin lines or to the right of required information on the origin line, provided that the information does not consist of numerals that resemble a ZIP Code or 3-digit ZIP Code prefix. It is recommended that this information be placed below the origin line. If placed above the destination line, the maximum height of the type is 0.083 inch, and it is further recommended that the information be printed in a size of type much smaller than the size used on the destination line. Extraneous information must not be placed between the destination and content lines.

3.3Barcode

The label barcode must meet these specifications:

a. Type of Barcode. The barcode must be an interleaved 2-of-5 code according to the Automatic Identification Manufacturers’ Uniform Symbology Specification (AIM/USS-I 2/5) with the exceptions noted below.

b. Information. The barcode must represent the following information: the 5-digit ZIP Code destination of the sack (for sacks with a 3-digit destination, this is the 3-digit ZIP Code prefix followed by two zeros); and the 3-digit content identifier number (CIN) applicable to the content of the sack in Exhibit 1.3.

c. Placement. The barcode must be on the left side of the sack label.

d. Quiet Zones. Two quiet zones (clear areas) must be maintained, one to the left and one to the right of the barcode, each measuring at least 10 times the X dimension (see 3.3f) and extending the full height of the barcode. The quiet zones must meet the space reflectance specification in 3.3i.

e. Height. The height of the barcode must be at least 0.700 inch.

f. X Dimension. The width of the narrow bar element and narrow space element is defined as the X dimension. It must be selected as a single dimension and it must be uniform within the barcode. The minimum X dimension or narrow element width is 0.012 inch and the maximum is 0.016 inch. The optimum X dimension or narrow bar/space width is 0.015 inch.

g. Wide-to-Narrow Bar Ratio. The wide-to-narrow ratio for bars and spaces within the barcode must be between 3 to 1 and 2.3 to 1 and be uniform within the barcode. The optimum ratio is 3 to 1.

h. Printing Tolerances. The maximum irregularity in the edge straightness of any bar element is 0.3 times the X dimension. The printing tolerance for any (narrow or wide) bar or space is +0.004 inch and is not cumulative. Example 1: If an X dimension of 0.015 inch is selected, each individual narrow bar or narrow space element on the printing of the barcode must not be less than 0.011 inch or more than 0.019 inch. Example 2: If the wide bar/space dimension of 0.045 inch is selected, each individual wide bar or space must not be less than 0.041 inch or more than 0.049 inch.

i. Reflectance. When measured at 633 nanometers, bar reflectance must be less than 30% and space reflectance must be more than 40%. The bar-to-space reflectance difference must be more than 40%.

Exhibit 1.3 3-Digit Content Identifier Numbers

[10-6-04] [10-30-03] The exact content identifier number (CIN) that matches the level of tray or sack must be used in the barcode and barcode numeric line on barcoded tray or sack labels. The required second line of information that corresponds to the CIN must appear on the human-readable content line of the label. The human-readable content line is automatically printed when labels are obtained through the PASSPORT system or ordered on Form 1578-B for printing at the Label Printing Center in Topeka, Kansas. A footnote at the end of the content line information means that the mailer must add appropriate information as required in modules L and M when ordering and printing tray and sack labels. Any mailer using PASSPORT to order labels must also add the appropriate additional information to the human-readable content line for those content lines marked with a footnote.

Class and Mailing |

CIN |

Human-Readable |

|---|---|---|

EXPRESS MAIL |

||

drop ship, all sack levels |

143 |

EXPRESS DROP SHIP |

PRIORITY MAIL |

||

drop ship, all sack levels |

165 |

PRIORITY DROP SHIP |

FIRST-CLASS MAIL |

||

FCM Letters — Automation |

||

carrier route trays |

263 |

FCM LTR CR BC1 |

5-digit carrier routes trays |

264 |

FCM LTR 5D CR-RT BC |

3-digit carrier routes trays |

265 |

FCM LTR 3D CR-RT BC |

5-digit scheme trays |

241 |

FCM LTR BC 5D SCHEME |

5-digit trays |

242 |

FCM LTR 5D BC |

3-digit scheme trays |

243 |

FCM LTR BC SCHEME2 |

3-digit trays |

244 |

FCM LTR 3D BC |

AADC trays |

245 |

FCM LTR AADC BC |

mixed AADC trays |

246 |

FCM LTR BC WKG |

FCM Letters — Presorted Machinable |

||

5-digit trays |

252 |

FCM LTR 5D MACH |

3-digit trays |

255 |

FCM LTR 3D MACH |

AADC trays |

258 |

FCM LTR AADC MACH |

mixed AADC trays |

260 |

FCM LTR MACH WKG |

FCM Letters — Presorted Nonmachinable |

||

5-digit trays |

267 |

FCM LTR 5D MANUAL |

3-digit trays |

269 |

FCM LTR 3D MANUAL |

ADC trays |

270 |

FCM LTR ADC MANUAL |

mixed ADC trays |

268 |

FCM LTR MANUAL WKG |

FCM Flats — Automation |

|

|

5-digit trays |

272 |

FCM FLTS 5D BC |

3-digit trays |

273 |

FCM FLTS 3D BC |

ADC trays |

274 |

FCM FLTS ADC BC |

mixed ADC trays |

275 |

FCM FLTS BC WKG |

FCM Flats — Presorted |

||

5-digit trays |

278 |

FCM FLTS 5D NON BC |

3-digit trays |

279 |

FCM FLTS 3D NON BC |

ADC trays |

280 |

FCM FLTS ADC NON BC |

mixed ADC trays |

282 |

FCM FLTS NON BC WKG |

FCM Flats — Cotrayed Automation and Presorted |

||

5-digit trays |

221 |

FCM FLTS 5D BC/NBC |

3-digit trays |

222 |

FCM FLTS 3D BC/NBC |

ADC trays |

231 |

FCM FLTS ADC BC/NBC |

mixed ADC trays |

232 |

FCM FLTS BC/NBC WKG |

FCM Parcels — Presorted |

||

5-digit sacks |

289 |

FCM PARCELS 5D |

3-digit sacks |

290 |

FCM PARCELS 3D |

ADC sacks |

291 |

FCM PARCELS ADC |

mixed ADC sacks |

292 |

FCM PARCELS WKG |

PERIODICALS (PER) |

|

|

PER Letters — Carrier Route |

||

saturation rate trays |

369 |

PER LTRS WSS1 |

high density rate trays |

370 |

PER LTRS WSH1 |

basic rate trays |

366 |

PER LTRS CR1 |

5-digit carrier routes trays |

367 |

PER LTRS CR-RTS |

3-digit carrier routes trays |

368 |

PER LTRS 3D CR-RTS |

PER Letters — Automation |

||

5-digit scheme trays |

341 |

PER LTRS BC 5D SCHEME |

5-digit trays |

342 |

PER LTRS 5D BC |

3-digit scheme trays |

343 |

PER LTRS BC SCHEME2 |

3-digit trays |

344 |

PER LTRS 3D BC |

AADC trays |

345 |

PER LTRS AADC BC |

mixed AADC trays |

346 |

PER LTRS BC WKG |

PER Letters — Nonautomation |

||

5-digit trays |

350 |

PER LTRS 5D NON BC |

3-digit trays |

353 |

PER LTRS 3D NON BC |

ADC trays |

356 |

PER LTRS ADC NON BC |

mixed ADC trays |

359 |

PER LTRS NON BC WKG |

PER Flats — Carrier Route |

||

car. rt. sacks — saturation |

387 |

PER FLTS WSS1 |

car. rt. sacks — high density |

388 |

PER FLTS WSH1 |

car. rt. sacks — basic |

385 |

PER FLTS CR1 |

5-digit carrier routes sacks |

386 |

PER FLTS CR-RTS |

5-digit scheme car. rts. sacks |

371 |

PER FLTS CR-RTS SCH |

PER Flats — Automation |

||

5-digit sacks |

372 |

PER FLTS 5D BC |

5-digit scheme sacks |

372 |

PER FLTS 5D SCH BC |

3-digit sacks |

373 |

PER FLTS 3D BC |

SCF sacks |

377 |

PER FLTS SCF BC |

ADC sacks |

374 |

PER FLTS ADC BC |

mixed ADC sacks |

375 |

PER FLTS BC WKG |

PER Flats — Nonautomation |

||

5-digit sacks |

378 |

PER FLTS 5D NON BC |

3-digit sacks |

379 |

PER FLTS 3D NON BC |

SCF sacks |

384 |

PER FLTS SCF NON BC |

ADC sacks |

380 |

PER FLTS ADC NON BC |

mixed ADC sacks |

382 |

PER FLTS NON BC WKG |

PER Flats — Cosacked Automation and Presorted |

||

5-digit sacks |

321 |

PER FLTS 5D BC/NBC |

3-digit sacks |

322 |

PER FLTS 3D BC/NBC |

SCF sacks |

329 |

PER FLTS SCF BC/NBC |

ADC sacks |

331 |

PER FLTS ADC BC/NBC |

mixed ADC sacks |

332 |

PER FLTS BC/NBC WKG |

PER Flats — Merged Carrier Route, Automation, and Presorted |

||

merged 5-digit sacks |

339 |

PER FLTS CR/5D |

merged 5-digit scheme sacks |

349 |

PER FLTS CR/5D SCH |

PER Irregular Parcels — Merged Carrier Route and Presorted |

||

merged 5-digit sacks |

340 |

PER IRREG CR/5D |

merged 5-digit scheme sacks |

365 |

PER IRREG CR/5D SCH |

|

PER Irregular Parcels — Carrier Route |

||

saturation rate sacks |

397 |

PER IRREG WSS1 |

high density rate sacks |

398 |

PER IRREG WSH1 |

basic rate sacks |

395 |

PER IRREG CR1 |

5-digit carrier routes sacks |

396 |

PER IRREG CR-RTS |

5-digit scheme car. rts. sacks |

399 |

PER IRREG CR-RTS SCH |

PER Irregular Parcels — Nonautomation |

||

5-digit sacks |

389 |

PER IRREG 5D |

3-digit sacks |

390 |

PER IRREG 3D |

SCF sacks |

394 |

PER IRREG SCF |

ADC sacks |

391 |

PER IRREG ADC |

mixed ADC sacks |

392 |

PER IRREG WKG |

PERIODICALS (NEWS) |

||

NEWS Letters — Carrier Route |

||

saturation rate trays |

469 |

NEWS LTRS WSS1 |

high density rate trays |

470 |

NEWS LTRS WSH1 |

basic rate trays |

466 |

NEWS LTRS CR1 |

5-digit carrier routes trays |

467 |

NEWS LTRS CR-RTS |

3-digit carrier routes trays |

468 |

NEWS LTRS 3D CR-RTS |

NEWS Letters — Automation |

||

5-digit scheme trays |

441 |

NEWS LTR BC 5D SCHEME |

5-digit trays |

442 |

NEWS LTRS 5D BC |

3-digit scheme trays |

443 |

NEWS LTRS BC SCHEME2 |

3-digit trays |

444 |

NEWS LTRS 3D BC |

AADC trays |

445 |

NEWS LTRS AADC BC |

mixed AADC trays |

446 |

NEWS LTRS BC WKG |

NEWS Letters — Nonautomation |

||

5-digit trays |

450 |

NEWS LTRS 5D NON BC |

3-digit trays |

453 |

NEWS LTRS 3D NON BC |

ADC trays |

456 |

NEWS LTRS ADC NON BC |

mixed ADC trays |

459 |

NEWS LTRS NON BC WKG |

NEWS Flats — Carrier Route |

||

car. rt. sacks — saturation |

487 |

NEWS FLTS WSS1 |

car. rt. sacks — high density |

488 |

NEWS FLTS WSH1 |

car. rt. sacks — basic |

485 |

NEWS FLTS CR1 |

5-digit carrier routes sacks |

486 |

NEWS FLTS CR-RTS |

5-digit scheme car. rts. sacks |

471 |

NEWS FLTS CR-RTS SCH |

NEWS Flats — Automation |

||

5-digit sacks |

472 |

NEWS FLTS 5D BC |

5-digit scheme sacks |

472 |

NEWS FLTS 5D SCH BC |

3-digit sacks |

473 |

NEWS FLTS 3D BC |

SCF sacks |

477 |

NEWS FLTS SCF BC |

ADC sacks |

474 |

NEWS FLTS ADC BC |

mixed ADC sacks |

475 |

NEWS FLTS BC WKG |

NEWS Flats — Nonautomation |

||

5-digit sacks |

478 |

NEWS FLTS 5D NON BC |

3-digit sacks |

479 |

NEWS FLTS 3D NON BC |

SCF sacks |

484 |

NEWS FLTS SCF NON BC |

ADC sacks |

480 |

NEWS FLTS ADC NON BC |

mixed ADC sacks |

482 |

NEWS FLTS NON BC WKG |

NEWS Flats — Cosacked Automation and Presorted |

||

5-digit sacks |

421 |

NEWS FLTS 5D BC/NBC |

3-digit sacks |

422 |

NEWS FLTS 3D BC/NBC |

SCF and origin/entry SCF sacks |

429 |

NEWS FLTS SCF BC/NBC |

ADC sacks |

431 |

NEWS FLTS ADC BC/NBC |

mixed ADC sacks |

432 |

NEWS FLTS BC/NBC WKG |

NEWS Flats — Merged Carrier Route, Automation, and Presorted |

||

merged 5-digit |

439 |

NEWS FLTS CR/5D |

merged 5-digit scheme |

449 |

NEWS FLTS CR/5D SCH |

NEWS Irregular Parcels — Merged Carrier Route and Presorted |

||

merged 5-digit |

440 |

NEWS IRREG CR/5D |

merged 5-digit scheme |

465 |

NEWS IRREG CR/5D SCH |

NEWS Irregular Parcels — Carrier Route |

||

saturation rate sacks |

497 |

NEWS IRREG WSS1 |

high density rate sacks |

498 |

NEWS IRREG WSH1 |

basic rate sacks |

495 |

NEWS IRREG CR1 |

5-digit carrier routes sacks |

496 |

NEWS IRREG CR-RTS |

5-digit scheme car. rts. sacks |

499 |

NEWS IRREG CR-RTS SCH |

NEWS Irregular Parcels — Nonautomation |

||

5-digit sacks |

489 |

NEWS IRREG 5D |

3-digit sacks |

490 |

NEWS IRREG 3D |

SCF sacks |

494 |

NEWS IRREG SCF |

ADC sacks |

491 |

NEWS IRREG ADC |

mixed ADC sacks |

492 |

NEWS IRREG WKG |

|

||

STANDARD MAIL |

|

|

ECR Letters — Automation |

||

carrier route trays |

563 |

STD LTR CR BC1 |

5-digit carrier routes trays |

564 |

STD LTR 5D CR-RT BC |

3-digit carrier routes trays |

565 |

STD LTR 3D CR-RT BC |

ECR Letters — Barcoded |

||

saturation rate |

557 |

STD LTR BC WSS1 |

high density rate |

557 |

STD LTR BC WSH1 |

basic rate |

557 |

STD LTR BC LOT1 |

5-digit carrier routes trays |

564 |

STD LTR 5D CR-RT BC |

3-digit carrier routes trays |

565 |

STD LTR 3D CR-RT BC |

ECR Letters — Nonautomation (Machinable) |

||

saturation rate |

569 |

STD LTR MACH WSS1 |

high density rate |

569 |

STD LTR MACH WSH1 |

basic rate |

569 |

STD LTR MACH LOT1 |

5-digit carrier routes trays |

567 |

STD LTR 5D CR-RT MACH |

3-digit carrier routes trays |

568 |

STD LTR 3D CR-RT MACH |

ECR Letters — Nonautomation (Nonmachinable) |

||

saturation rate |

608 |

STD LTR MAN WSS1 |

high density rate |

608 |

STD LTR MAN WSH1 |

basic rate |

608 |

STD LTR MAN LOT1 |

5-digit carrier routes trays |

609 |

STD LTR 5D CR-RT MAN |

3-digit carrier routes trays |

611 |

STD LTR 3D CR-RT MAN |

STD Letters — Automation |

||

5-digit scheme trays |

541 |

STD LTR BC 5D SCHEME |

5-digit trays |

542 |

STD LTR 5D BC |

3-digit scheme trays |

543 |

STD LTR BC SCHEME2 |

3-digit trays |

544 |

STD LTR 3D BC |

AADC trays |

545 |

STD LTR AADC BC |

mixed AADC trays |

546 |

STD LTR BC WKG |

STD Letters — Presorted Machinable |

||

5-digit trays |

552 |

STD LTR 5D MACH |

3-digit trays |

555 |

STD LTR 3D MACH |

AADC trays |

558 |

STD LTR AADC MACH |

mixed AADC trays |

560 |

STD LTR MACH WKG |

STD Letters — Presorted Nonmachinable |

||

5-digit trays |

604 |

STD LTR 5D MANUAL |

3-digit trays |

606 |

STD LTR 3D MANUAL |

ADC trays |

607 |

STD LTR ADC MANUAL |

mixed ADC trays |

605 |

STD LTR MANUAL WKG |

Enhanced Carrier Route Flats — Nonautomation |

||

saturation rate sacks |

587 |

STD FLTS ECRWSS1 |

high density rate sacks |

588 |

STD FLTS ECRWSH1 |

basic rate sacks |

589 |

STD FLTS ECRLOT1 |

5-digit carrier routes sacks |

586 |

STD FLTS CR-RTS |

5-digit scheme car. rts. sacks |

529 |

STD FLTS CR-RTS SCH |

STD Flats — Cosacked Automation and Presorted |

||

5-digit sacks |

521 |

STD FLTS 5D BC/NBC |

3-digit and origin/entry 3-digit sacks |

522 |

STD FLTS 3D BC/NBC |

ADC sacks |

531 |

STD FLTS ADC BC/NBC |

mixed ADC sacks |

532 |

STD FLTS BC/NBC WKG |

STD Flats — Merged Carrier Route, Automation, and Presorted |

||

merged 5-digit |

539 |

STD FLTS CR/5D |

merged 5-digit scheme |

549 |

STD FLTS CR/5D SCH |

STD Flats — Automation |

||

5-digit sacks |

572 |

STD FLTS 5D BC |

5-digit scheme sacks |

572 |

STD FLTS 5D SCH BC |

3-digit sacks |

573 |

STD FLTS 3D BC |

ADC sacks |

574 |

STD FLTS ADC BC |

mixed ADC sacks |

575 |

STD FLTS BC WKG |

STD Flats — Presorted |

||

5-digit sacks |

578 |

STD FLTS 5D NON BC |

3-digit sacks |

579 |

STD FLTS 3D NON BC |

ADC sacks |

580 |

STD FLTS ADC NON BC |

mixed ADC sacks |

582 |

STD FLTS NON BC WKG |

Customized MarketMail (CMM) |

||

CMM letter trays |

206 |

DEL LTR STD CMM MAN |

CMM flat trays |

207 |

DEL FLTS STD CMM MAN |

CMM sacks |

205 |

DEL STD CMM MAN |

ECR Irregular Parcels — Nonautomation |

||

saturation rate sacks |

599 |

STD IRREG WSS1 |

high density rate sacks |

600 |

STD IRREG WSH1 |

basic rate sacks |

601 |

STD IRREG LOT1 |

5-digit carrier routes sacks |

598 |

STD IRREG CR-RTS |

STD Irregular Parcels — Presorted |

||

5-digit sacks |

590 |

STD IRREG 5D |

5-digit scheme sacks |

590 |

STD IRREG 5D SCH |

3-digit sacks |

591 |

STD IRREG 3D |

ADC sacks |

592 |

STD IRREG ADC |

mixed ADC sacks |

594 |

STD IRREG WKG |

STD Machinable Parcels — Presorted |

||

5-digit sacks |

670 |

STD MACH 5D |

5-digit scheme sacks |

670 |

STD MACH 5D SCH |

ASF sacks |

672 |

STD MACH ASF |

BMC sacks |

673 |

STD MACH BMC |

mixed BMC sacks |

674 |

STD MACH WKG |

STD Machinable and Irregular Parcels — Presorted |

||

5-digit sacks |

603 |

STD MACH-IRREG 5D |

5-digit scheme sacks |

603 |

STD MACH-IRREG 5D SCH |

|

||

PACKAGE SERVICES |

||

Carrier Route BPM — Flats |

||

carrier route sacks |

657 |

PSVC FLTS CR1 |

5-digit scheme car. rts. sacks |

659 |

PSVC FLTS CR-RTS SCH |

5-digit carrier routes sacks |

658 |

PSVC FLTS CR-RTS |

Presorted BPM — Flats |

||

5-digit sacks |

649 |

PSVC FLTS 5D NON BC |

3-digit sacks |

650 |

PSVC FLTS 3D NON BC |

SCF sacks |

654 |

PSVC FLTS SCF NON BC |

ADC sacks |

651 |

PSVC FLTS ADC NON BC |

mixed ADC sacks |

653 |

PSVC FLTS NON BC WKG |

Presorted BPM — Automation Flats |

||

5-digit sacks |

635 |

PSVC FLTS 5D BC |

5-digit scheme sacks |

635 |

PSVC FLTS 5D SCH BC |

3-digit sacks |

636 |

PSVC FLTS 3D BC |

SCF sacks |

637 |

PSVC FLTS SCF BC |

ADC sacks |

638 |

PSVC FLTS ADC BC |

mixed ADC sacks |

639 |

PSVC FLTS BC WKG |

BPM Flats — Cosacked Barcoded and Presorted |

||

5-digit sacks |

648 |

PSVC FLTS 5D BC/NBC |

3-digit sacks |

661 |

PSVC FLTS 3D BC/NBC |

SCF sacks |

667 |

PSVC FLTS SCF BC/NBC |

ADC sacks |

668 |

PSVC FLTS ADC BC/NBC |

mixed ADC sacks |

669 |

PSVC FLTS BC/NBC WKG |

Carrier Route BPM — Irregular Parcels |

||

carrier route sacks |

697 |

PSVC IRREG CR1 |

5-digit carrier routes sacks |

698 |

PSVC IRREG CR-RTS |

5-digit scheme car. rt. sacks |

698 |

PSVC IRREG CR-RTS SCH |

Presorted BPM — Irregular Parcels |

||

5-digit sacks |

690 |

PSVC IRREG 5D |

5-digit scheme sacks |

690 |

PSVC IRREG 5D SCH |

3-digit sacks |

691 |

PSVC IRREG 3D |

SCF sacks |

696 |

PSVC IRREG SCF |

ADC sacks |

692 |

PSVC IRREG ADC |

mixed ADC sacks |

694 |

PSVC IRREG WKG |

Carrier Route BPM — Machinable Parcels |

||

carrier route sacks |

687 |

PSVC MACH CR1 |

Presorted BPM — Machinable Parcels |

||

5-digit sacks |

680 |

PSVC MACH 5D |

5-digit scheme sacks |

680 |

PSVC MACH 5D SCH |

ASF sacks |

682 |

PSVC MACH ASF |

BMC sacks |

683 |

PSVC MACH BMC |

mixed BMC sacks |

684 |

PSVC MACH WKG |

Media Mail and Library Mail Flats — Presorted |

||

5-digit sacks |

649 |

PSVC FLTS 5D NON BC |

3-digit sacks |

650 |

PSVC FLTS 3D NON BC |

ADC sacks |

651 |

PSVC FLTS ADC NON BC |

mixed ADC sacks |

653 |

PSVC FLTS NON BC WKG |

Media Mail and Library Mail Irregular Parcels — Presorted |

||

5-digit scheme sacks |

690 |

PSVC IRREG 5D SCH |

5-digit sacks |

690 |

PSVC IRREG 5D |

3-digit sacks |

691 |

PSVC IRREG 3D |

ADC sacks |

692 |

PSVC IRREG ADC |

mixed ADC sacks |

694 |

PSVC IRREG WKG |

Media Mail and Library Mail Machinable Parcels — Presorted |

||

5-digit scheme sacks |

680 |

PSVC MACH 5D SCH |

5-digit sacks |

680 |

PSVC MACH 5D |

3-digit sacks |

682 |

PSVC MACH ASF |

ADC sacks |

683 |

PSVC MACH BMC |

mixed ADC sacks |

684 |

PSVC MACH WKG |

Parcel Post Machinable Parcels |

||

5-digit sacks |

680 |

PSVC MACH 5D |

5-digit scheme sacks |

680 |

PSVC MACH 5D SCH |

ASF sacks |

682 |

PSVC MACH ASF |

BMC sacks |

683 |

PSVC MACH BMC |

mixed BMC sacks |

684 |

PSVC MACH WKG |

Parcel Post DSCF and DDU Rates |

||

5-digit sacks |

688 |

PSVC PARCELS 5D |

5-digit scheme sacks |

688 |

PSVC PARCELS 5D SCH |

Parcel Post—Irregular (Nonmachinable) Parcels |

||

3-digit sacks |

691 |

PSVC IRREG 3D |

Combined PSVC Parcels |

||

5-digit sacks |

688 |

PSVC PARCELS 5D |

5-digit scheme sacks |

688 |

PSVC PARCELS 5D SCH |

Combined STD & PSVC Machinable Parcels |

||

5-digit sacks |

660 |

STD/PSVC MACH 5D |

5-digit scheme sacks |

660 |

STD/PSVC MACH 5D SCH |

ASF sacks |

662 |

STD/PSVC MACH ASF |

BMC sacks |

663 |

STD/PSVC MACH BMC |

mixed BMC sacks |

664 |

STD/PSVC MACH WKG |

DMM Issue 58 Updated 12-9-04