DMM TOC > 300 Discount Flats301 Physical Standards1.0 Physical Standards for Flats1.1 General Definition of Flat Size MailFlat-size mail other than that in 3.0, Physical Standards for Automation Flats, is: a. More than 11-1/2 inches long, or more than 6-1/8 inches high, or more than 1/4 inch thick. b. Not more than 15 inches long, or more than 12 inches high, or greater than 3/4 inch thick. c. Unwrapped, sleeved, wrapped, or enveloped. d. Pieces are subject to the minimum standards in 601.1.2 and may be subject to other minimum dimensions, based on the standards for specific rates. 1.2 Length and Height of FlatsThe location and orientation of the delivery address on a mailpiece generally establish which dimensions of the piece are the length and the height. The length is the dimension parallel to the address as read; the height is the dimension perpendicular to the length; the top and bottom of the piece are the upper and lower edges, respectively, when the address is positioned for normal reading. This general rule does not apply to: b. Standard Mail Enhanced Carrier Route flats. c. Standard Mail Customized MarketMail. d. Pieces thicker than 1/4 inch that are not prepared and mailed as a flat. 2.0 Physical Standards for Presorted (Nonautomation) Flats2.1 First-Class Mail2.1.1 Maximum WeightMatter at First-Class Mail rates cannot exceed 13 ounces. First-Class Mail weighing more than 13 ounces is Priority Mail. (Lower size or weight standards apply to mail claimed at certain rates or addressed to certain APOs and FPOs.) 2.1.2 Nonmachinable SurchargeFirst-Class Mail flats that weigh 1 ounce or less are subject to the nonmachinable surcharge if any one of the following applies (see 1.2 for how to determine the length and height of a mailpiece): a. The piece is greater than 1/4-inch thick. b. The length is more than 11-1/2 inches or the height is more than 6-1/8 inches. c. The aspect ratio (length divided by height) is less than 1.3 or more than 2.5. 2.2 Standard Mail2.2.1 Basic Physical StandardsThese standards apply to Standard Mail: a. Each piece must weigh less than 16 ounces. b. Except for automation basic carrier route rate pieces and merchandise samples mailed with detached address labels (DALs), the maximum size for Enhanced Carrier Route Standard Mail is 14 inches long, 11-3/4 inches high, and 3/4 inch thick (see Exhibit 2.2.1b). Merchandise samples whose dimensions exceed these maximums may be sent at the Enhanced Carrier Route rates if mailed using DALs, provided that the samples meet all other applicable standards and the DALs meet the standards in 602.4.0.

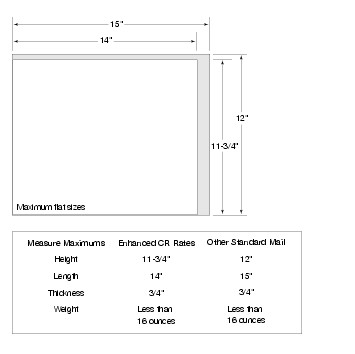

Exhibit 2.2.1b Maximum Dimensions for Standard Mail Flats

|

|

Affixing address labels to outside of polywrap is an alternative to meeting this requirement. |

|||

3.5.2 Wrap Direction and Seam Placement

Wrap direction, seam direction, and seam placement must follow these standards:

a. Wrap direction and seam direction:

1. For an AFSM 100 mailpiece, the wrap direction must be around the longer axis of the mailpiece, with the seam parallel to that axis. The longer axis is always parallel to the longer edge (the length) of the mailpiece.

2. For a UFSM 1000 mailpiece, the wrap direction may be around either the longer axis or the shorter axis of the mailpiece, with the seam parallel to that axis. The longer axis is always parallel to the longer edge (the length) of the mailpiece, and the shorter axis is always parallel to the shorter edge (the height) of the mailpiece.

b. For either an AFSM 100 or a UFSM 1000 mailpiece, the preferred seam placement is on the nonaddressed side of the mailpiece. If the seam is placed on the addressed side, the seam must not cover any part of the delivery address and barcode, postage area, or any required markings or endorsements. Regardless of seam placement, the polywrap over the address area must be a smooth surface to avoid interference with address and barcode readability.

3.5.3 Overhang

For purposes only of the polywrap standards for overhang (selvage) in 3.5, the edge of the mailpiece designated as top must be one of the two physically longer edges of the piece, regardless of address orientation and whether bound or unbound. Any polywrap overhang (selvage) around the four edges of the mailpiece (top, bottom, and left and right sides) must meet these standards:

1. When the mailpiece contents are totally positioned at the bottom of the polywrap, the overhang must not be more than 0.5 inch at the top of the mailpiece.

2. When the mailpiece contents are totally positioned to the left or to the right side of the polywrap, the overhang must not be more than 1.5 inches on the opposite side.

3. The polywrap covering must not be so tight that it bends the mailpiece.

1. When the mailpiece contents are totally positioned at the bottom of the polywrap, the overhang must not be more than 1.5 inches at the top of the mailpiece.

2. When the mailpiece contents are totally positioned to the left or to the right side of the polywrap, the overhang must not be more than 1.5 inches on the opposite side.

3. The polywrap covering must not be so tight that it bends the mailpiece.

3.5.4 Polywrap on Mailpieces

[2-4-07] Effective March 4, 2007, mailers claiming automation flat rates for polywrapped pieces must use polywrap that meets the new specifications in 3.5.1. Only products listed on the USPS RIBBS Web site (http://ribbs.usps.gov) may be used on automation-rate flats.

3.5.5 Polywrap Certification Process for Manufacturers

[2-4-07] To ensure that all polywrap manufacturers use the same criteria in meeting the new specifications, the Postal Service developed specification USPS-T-3204, Test Procedures for Automatable Polywrap Films. This specification describes exact test procedures and acceptable values for polywrap film characteristics. Independent testing laboratories may certify products for manufacturers who do not have the facilities or experience to conduct each of the test procedures in specification USPS-T-3204. The specification includes a list of laboratories experienced in conducting these tests. Customers may obtain the new test procedures by contacting USPS Engineering (see 608.8.1 for address) or on the USPS RIBBS Web site (http://ribbs.usps.gov). Effective February 4, 2007, manufacturers must submit a letter, on their letterhead, indicating the value for each of the specifications in 3.5.1 for each polywrap film, to USPS Mailing Standards (see 608.8.1 for address). Manufacturers are encouraged to submit the certificate of conformance before February 4, 2007. When USPS receives the certificate of conformance, films with values meeting the standards will be listed on http://ribbs.usps.gov. Manufacturers should follow this process before submitting the letter certifying compliance with the specifications:

a. Test each film according to procedures listed in USPS-T-3204, Test Procedures for Automatable Polywrap Films.

b. Test each surface treatment separately. Manufacturers may test the thinnest film of one product with identical surface treatment and characteristics. If the thinnest film satisfactorily meets the characteristics after being tested, USPS will list the product as approved for all gauges of that product that also meet the gauge test.

3.6 Prohibitions

3.6.1 Protrusions

Clasps, strings, buttons, or like materials, or other protrusions that impede or damage mail processing equipment are prohibited.

3.6.2 Staples

Staples must not be substituted for tabs or wafer seals on pieces in automation rate mailings. As a binding method, staples may be placed in the fold or spine of a magazine or booklet-type or similar mailpiece if parallel with the bound edge, tightly and securely inserted, and not protruding to damage or interfere with mail processing equipment.

3.7 Tabs, Wafer Seals, Tape, and Glue

3.7.1 General

Although not required, mailpieces may be prepared with tabs, wafer seals, cellophane tape, or permanent glue (continuous or spot) if these sealing devices do not interfere with the recognition of the barcode, rate marking, postage information, and delivery and return addresses. Cellophane tape may not be placed over the barcode or where any part of the barcode will be printed. Tabs or seals placed in the area on which any part of the barcode is printed must contain a paper face meeting the standards for background reflectance. Tabs, wafer seals, and tape must have a peel adhesion (shear strength) value of at least 15 ounces/inch at a speed of 12 inches/minute after application to a stainless steel plate; the test is to be conducted 10 minutes after the material is applied to the plate.

3.7.2 Short Covers

Flats may be prepared with a cover page or protective cover that is more than 3/4 inch from each edge if the cover page is secured with at least two tabs, wafer seals, or glue spots placed within 1 inch of the top and bottom edges of the cover page or protective cover.

3.8 Uniformity and Exterior Format

3.8.1 General Requirements

A flat-size mailpiece prepared and claimed at automation rates must be uniformly thick. Each flat-size mailpiece must have a smooth and regular shape and be free of creases, folds, tears, or other irregularities not compatible with automation equipment. The exterior surface must not have protuberances caused by prohibited closures; attachments (except as provided below); irregularly shaped or distributed contents; or untrimmed excess material from the envelope, wrapper, or sleeve.

3.8.2 Outside Attachment

An attachment to a flat-size mailpiece must be a single sheet, the same size as the cover. The attachment must be permanently, securely, and uniformly affixed to the front or back cover along a bound, folded, or otherwise closed edge. Pieces claimed at a Periodicals rate may bear attachments only if permitted by the applicable standards.

3.8.3 Contents

The contents of a flat-size mailpiece must remain uniformly thick so that the dimensions of the envelope, wrapper, or sleeve remain constant. If the contents are of irregular thickness or significantly smaller than the envelope, wrapper, or sleeve, those contents must be secured in place to prevent shifting within the wrapping during processing and surrounded with loose packing material or padding to ensure that the mailpiece remains uniformly thick.

3.8.4 Booklet-Type Piece or Magazine

The contents of flat-size mailpieces prepared in sleeves or other wrappers must be sufficiently secure in the sleeve or wrapper to stay in place during processing. If material bearing the delivery address or barcode for the mailpiece is enclosed in a partial wrapper, that wrapper must be sufficiently secure to prevent the contents from shifting and obscuring the delivery address or barcode.

3.9 Outside Labels and Stickers

3.9.1 Use

Permanent labels and stickers (those designed not to be removed or relocated) must be affixed directly to the outside of the mailpiece with permanent adhesive. A mailer may provide recipients with relocatable labels to place on the outside of response pieces sent back to the mailer. On pieces mailed at Periodicals rates, labels and stickers may be used only if permitted by the applicable standards.

3.9.2 Pressure-Sensitive Label

Any pressure-sensitive label or sticker affixed directly to a mailpiece before mailing must have a minimum peel adhesion to stainless steel of 8 ounces/inch. This standard does not apply to pressure-sensitive labels provided by the USPS to label bundles to sortation levels.

3.9.3 "Sandwich" Label

A face stock/liner label ("sandwich" label) is a two-part unit with a face stock (top label) attached to a liner (bottom label) affixed to the mailpiece. The face stock must have a peel adhesion value of at least 2 ounces/inch with respect to the liner label and at least 8 ounces/inch when reapplied to stainless steel.