|

January 2006

Related QSGs

Physical Standards (401) Standard Mail: maximum weight is less than 16 ounces. Bound Printed Matter: maximum weight is 15 pounds. Parcel Post: maximum weight is 35 pounds (25 pounds for books and other printed matter). Dimensions: 6 to 34 inches long, 3 to 17 inches high, and 1/4 to 17 inches thick. Parcels 1/4 thick must be at least 3-1/2 inches high and 6 inches long. For an overview of the physical standards for discount parcels, see Quick Service Guide 401.

Eligibility Standards Barcoded discount: Standard Mail and Package Services (Parcel Post, Bound Printed Matter, Media Mail, and Library Mail) barcoded discount pieces must meet the standards in 708.5.1. Parcel barcode may be combined with Delivery Confirmation or Signature Confirmation Service barcode. Standard Mail parcels may include only electronic Delivery Confirmation. Parcels eligible for the Standard Mail and Package Services barcoded discount must be prepared with the address and barcode placed squarely onto the largest surface area of the parcel except when the shape and contents require specific orientation for stability during processing. The barcode should be placed immediately adjacent to the delivery address and no closer than 1/2 inch from the edge of the parcel.

Acceptable Container (601.3) Size must be adequate to contain items and provide space for cushioning material:

Cushioning (601.4)

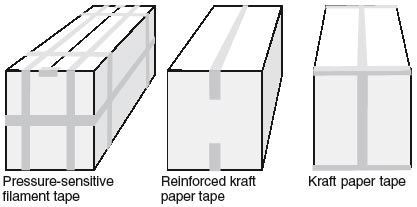

Closure and Sealing (601.4)

Mail Preparation

For pallet preparation, see 705.8. For combined mailings of Standard Mail and Package Services parcels, see 705.6. For the specific DMM standards applicable to this category of mail, consult the DMM sections referenced above and the general sections within each DMM module.

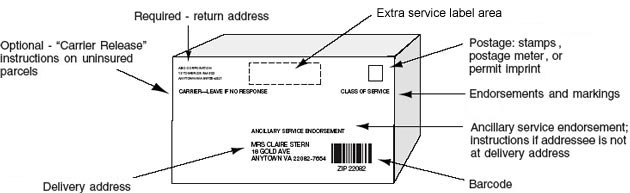

Physical Standards for Automation-Compatible Parcels Required - return address (602.1.5) Optional - "Carrier Release" instructions on uninsured parcels (508.1.2) Delivery Address (602.1.3) Extra service label area (503) Postage: stamps (604.1), postage meter (604.4), or permit imprint (604.6) Endorsements and markings (302) Ancillary service endorsement; Instructions if addressee is not at delivery address (507) Barcode (708.5.1)

UCC/EAN Code 128 Barcode If the barcode is printed on the delivery address label and in close proximity to the address, the ZIP Code or ZIP+4 code information below the barcode may be omitted. If the barcode is printed on a separate label, the ZIP Code or ZIP+4 code preceded by the word "ZIP" must be printed between 1/8 inch and 1/2 inch below the barcode.

Postal routing codes must meet the technical specifications in the UCC/EAN Code 128; see 708.5.1. Packaging and Sealing

Cushioning:

Sealing (see front for details):

|

Container (see front for details):

Container (see front for details):