201 Physical Standards

1.0 Physical Standards for Machinable Letters and Cards

1.1 Physical Standards for Machinable Letters

1.1.1 Dimensional Standards for Letters

[5-11-09] Machinable letter-size mail is:

a. Not less than 5 inches long, 3-1/2 inches high, and 0.007-inch thick.

b. Not more than 11-1/2 inches long, or more than 6-1/8 inches high, or greater than 1/4-inch thick.

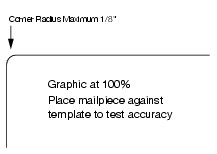

c. Rectangular, with four square corners and parallel opposite sides. Letter-size, card-type mailpieces made of cardstock may have finished corners that do not exceed a radius of 0.125 inch (1/8 inch). See Exhibit 1.1.1d.

d. Within an aspect ratio (length divided by height) of 1.3 to 2.5, inclusive. See 601.1.4.

Exhibit 1.1.1d Maximum Corner Radius for Letter-Size, Card-Type Mailpieces

1.1.2 Weight Standards for Machinable Letters

The maximum weight for Presorted First-Class Mail machinable letters is 3.3 ounces (0.2063 pound). The maximum weight for Standard Mail machinable letters is 3.3 ounces (0.2063 pound).

1.1.3 All Machinable Letters

5-11-09] All pieces of First-Class Mail and Standard Mail machinable letters must meet the standards for automation-compatible letters in 3.0.

1.2 Physical Standards for Cards Claimed at Card Prices

1.2.1 Dimensional Standards for Cards

Each card (each stamped card or postcard or each half of a double stamped card or postcard) claimed at a card price must be:

a. Not less than 3-1/2 inches high, 5 inches long, and 0.007 inch thick.

b. Not more than 4-1/4 inches high, or more than 6 inches long, or greater than 0.016 inch thick.

c. Rectangular, with four square corners and parallel opposite sides. Card-size pieces meeting the standards in 1.2.1 may have finished corners that do not exceed a radius of 0.125 inch (1/8 inch). See Exhibit 1.1.1d.

1.2.2 Other Cards

A card that does not meet the applicable standards in 1.2 must not bear the words "Postcard" or "Double Postcard."

1.2.3 Paper or Cardstock

A card must be of uniform thickness and made of unfolded and uncreased paper or cardstock of approximately the quality and weight of a stamped card (i.e., a card available from the USPS). A card must be formed either of one piece of paper or cardstock or of two pieces of paper permanently and uniformly bonded together. The stock used for a card may be of any color or surface that permits the legible printing of the address, postmark, and any required markings.

1.2.4 Acceptable Attachments

A card may bear an attachment that is:

a. A paper label, such as a wafer seal or decal affixed with permanent adhesive to the back side of the card, or within the message area on the address side (see 1.2.6), or to the left of the address block.

b. A label affixed with permanent adhesive for showing the delivery or return address.

c. A small reusable seal or decal prepared with pressure-sensitive and nonremovable adhesive that is intended to be removed from the first half of a double card and applied to the reply half.

1.2.5 Unacceptable Attachment

A card may not bear an attachment that is:

a. Other than paper.

b. Not totally adhered to the card surface.

c. An encumbrance to postal processing.

1.2.6 Address Side of Cards

The address side of a card is the side bearing the delivery address and postage. The address side may be formatted to contain a message area. Cards that do not contain a message area on the address side are subject to the applicable standards for the price claimed. For the purposes of 1.2, miscellaneous graphics or printing, such as symbols, logos, or characters, that appear on the address side of cards not containing a message area are generally acceptable provided the items are not intended to convey a message. Cards claimed at the Presorted or automation card prices that contain a message area on the address side must be divided vertically or horizontally and meet the following additional standards, as applicable:

a. Vertically divided cards.

1. The address side of the card must be divided into a right portion and a left portion, with or without a vertical rule. The left portion is the message area.

2. The delivery address, postage, and any USPS marking or endorsement must appear in the right portion. The right portion must be at least 2-1/8 inches wide (measured from the right edge of the card, top to bottom inclusive).

3. For cards claimed at the Presorted price, nondelivery address information may extend into the right portion only above the address block and if the information is shaded or surrounded by a border that has at least 1/8 inch clearance between the delivery address block and the border. Mailers may choose not to shade or border the nondelivery address information if there is at least 1/8 inch of clear space around the delivery address block.

4. For cards claimed at the automation price, the standards for automation-compatible mail in 3.0, Physical Standards for Machinable and Automation Letters and Cards, and 202.5.0, Barcode Placement, must be met.

b. Horizontally divided cards.

1. The address side of the card must be divided into an upper portion and a lower portion, with or without a horizontal rule. The portion of the address side that does not contain the delivery address is the message area.

2. The delivery address, postage, and any USPS marking or endorsement must appear within the portion containing the delivery address. As an alternative, when the delivery address appears within the lower portion, it is permissible for the postage, return address, and any USPS marking or endorsement to appear in the upper portion. The portion bearing the delivery address must be at least 1-1/2 inches high (measured from the top or bottom edge of the card, as applicable, right edge to left edge inclusive).

3. For cards claimed at the Presorted price, nondelivery address information may extend into the portion containing the delivery address only if it appears above the address block and if the information is shaded or surrounded by a border that has at least 1/8 inch clearance between the delivery address block and the border. Mailers may choose not to shade or border the nondelivery address information if there is at least 1/8 inch of clear space around the delivery address block.

4. For cards claimed at the automation price, the standards for automation-compatible mail in 3.0, Physical Standards for Machinable and Automation Letters and Cards, and 202.5.0, Barcode Placement, must be met.

1.2.7 Tearing Guides

A card may have perforations or tearing guides if they do not eliminate or interfere with any address element, postage, marking, or endorsement and do not impair the physical integrity of the card.

1.2.8 Double Cards

A double card (a double stamped card or double postcard) consists of two attached cards, one of which is designed to be detached by the recipient and returned by mail as a single card. Double cards are subject to these standards:

a. The reply half of a double card must be used for reply only and may not be used to convey a message to the original addressee or to send statements of account. The reply half may be formatted for response purposes (e.g., contain blocks for completion by the addressee).

b. A double card must be folded before mailing and prepared so that the address on the reply half is on the inside when the double card is originally mailed. The address side of the reply half may be prepared as business reply mail, courtesy reply mail, meter reply mail, or as a merchandise return service label.

c. Plain stickers, seals, or a single wire stitch (staple) may be used to fasten the open edge at the top or bottom once the card is folded if affixed so that the inner surfaces of the cards can be readily examined. Fasteners must be affixed according to the applicable preparation requirements for the price claimed. Any sealing on the left and right sides of the cards, no matter the sealing process used, is not permitted.

d. The first half of a double card must be detached when the reply half is mailed for return.

1.2.9 Enclosures in Double Cards

Enclosures in double postcards are prohibited at card prices.

Back to Top

2.0 Physical Standards for Nonmachinable Letters

2.1 Criteria for Nonmachinable Letters

[5-11-09] A letter-size piece is nonmachinable if it has an exterior surface that is not made of paper or if it does not meet the standards in 3.0. Windows in envelopes made of paper do not make mailpieces nonmachinable. Attachments do not render mailpieces nonmachinable if allowed by eligibility standards according to the class of mail and if not prohibited in 3.0. In addition, a letter-size piece is nonmachinable if it weighs more than 3.3 ounces (up to 3.5 ounces) unless it has a barcode and is eligible for and claims automation letter prices or Standard Mail Carrier Route letter prices.

2.2 Additional Criteria for First-Class Mail Nonmachinable Letters

Letter-price pieces (except card-price pieces) that meet one or more of the nonmachinable characteristics in 2.1 are subject to the nonmachinable surcharge (see 133.1.10). All letter-size pieces over 3.5 ounces are prepared as letters and charged the flat-size prices.

2.3 Additional Criteria for Standard Mail Nonmachinable Letters

The nonmachinable prices in 243.1.5 apply to Standard Mail letter-size pieces that weigh 3.3 ounces or less and have one or more of the nonmachinable characteristics in 2.1. Mailers must prepare nonmachinable letters over 3.3 ounces as described in 245.5.0, mark each piece "Not Flat-Machinable" or "NFM" as described in 402.2.0, and pay the Not Flat-Machinable prices.

2.4 Additional Criteria for Periodicals Nonmachinable Letters

The nonbarcoded letter prices in 707. apply to Periodicals letter-size pieces that have one or more of the nonmachinable characteristics in 2.1.

Back to Top

3.0 Physical Standards for Machinable and Automation Letters and Cards

3.1 Basic Standards for Automation Letters and Cards

[8-14-08] Letters and cards claimed at automation letter prices and at Standard Mail Enhanced Carrier Route prices must meet the standards in 3.0. Unless prepared as a self-mailer, booklet, or postcard under 3.14.1 through 3.14.3, each mailpiece must be a sealed envelope (the preferred method) or, if unenveloped, must be sealed or glued along all four sides. All references in 3.0 to paper basis weight are based on measured weight for 500 17-inch by 22-inch sheets. Envelopes, or letter-size mailpieces sealed along all four sides, must be made of paper with a minimum 16 pounds basis weight or equivalent. See 3.4 for additional standards for mailpieces with disc enclosures.

3.2 Dimension and Shape Standards for Machinable and Automation Letters

Each letter-size piece must be rectangular (see 1.1.1) and:

a. For height, no more than 6-1/8 or less than 3-1/2 inches high.

b. For length, no more than 11-1/2 or less than 5 inches long.

c. For thickness, no more than 0.25 or less than

1. 0.007 inch thick if no more than 4-1/4 inches high and 6 inches long; or

2. 0.009 inch thick if more than 4-1/4 inches high or 6 inches long, or both.

3.3 Standards for Letter-Size Pieces Containing Discs (CDs or DVDs)

3.3.1 Basic Standards for Discs in Envelopes

Letter-size mailpieces containing a single disc and meeting the standards in 3.3 are considered automation-compatible. Mailpieces with one enclosed disc not meeting these standards must be tested and approved for automation-compatibility.

3.3.2 Disc Size and Placement

Position the disc symmetrically at the vertical centerline and as near to the top edge of the mailpiece as is practical. Secure the disc to prevent it from shifting more than 1/2 inch in any direction. The maximum disc size is:

a. 120 mm (4.7 inches) in diameter.

b. 2 mm (0.08 inch) in thickness.

3.3.3 Dimensions and Shape Standards for Automation-Compatible Enveloped Letters Containing Discs

Each enveloped letter must meet the basic standards for machinable letters in 1.0 and have the following characteristics:

a. Height, not more than 6 inches or less than 5.5 inches high.

b. Length, not more than 9.75 inches or less than 7.25 inches long.

c. Thickness, not more than 0.25 inch or less than 0.009 inch thick.

d. Weight, not more than 3 ounces.

e. A piece up to 8 inches long must be made of paper with a minimum 28-pound basis weight or equivalent.

f. A piece over 8 inches long (up to 9.75 inches long) must be made of paper with a minimum 32-pound basis weight or equivalent.

g. Discs in mailpieces made of the minimum basis weight paper must be inserted into a protective sleeve.

3.3.4 Dimensions and Shape Standards for Automation-Compatible Folded Self-Mailers Containing Discs

Each folded self-mailer must meet the basic standards for machinable letters in 1.0 and have the following characteristics:

a. Height, not more than 6 inches or less than 5.5 inches high.

b. Length, not more than 9.75 inches or less than 7.25 inches long.

c. Thickness, not more than 0.25 inch or less than 0.009 inch thick.

d. Weight, not more than 3 ounces.

e. Be prepared from paper stock meeting the industry standard for a basis weight of 75 pounds or greater, with none less than 71.25 pounds (measured weight for 500 25- by 38-inch sheets). The stock must be free from groundwood unless coated with a substance adding to the stock's ability to resist an applied bending force.

f. Any folds or perforations in the mailpiece must be parallel to the address.

g. Must meet the tabbing requirements for pieces prepared with folds or perforations parallel to the address provided in 3.14.

3.3.5 Unacceptable Characteristics for Automation-Compatible Letter-Size Pieces with Discs

Discs in letter-sized envelopes and folded self-mailers may not be enclosed in:

a. Packaging such as plastic "clamshells," plastic "jewel cases," or inflexible cardboard sleeves.

b. Window envelopes.

3.4 Weight Standards for First-Class Mail Automation Letters and Cards

Maximum weight for First-Class Mail automation letters is 3.5 ounces (0.2188 pound). See 3.14.4 for pieces heavier than 3 ounces.

3.5 Weight Standards for Standard Mail Automation Letters

Maximum weight for Standard Mail mailed at automation and Enhanced Carrier Route letter prices is 3.5 ounces (0.2188 pound). See 3.14.4 for pieces heavier than 3 ounces.

3.6 Weight Standards for Periodicals Barcoded (Automation) Letters

The maximum weight for Periodicals barcoded (automation) letters is 3.5 ounces (0.2188 pound). See 3.14.4 for pieces heavier than 3 ounces.

3.7 Aspect Ratio

The aspect ratio (length of the mailpiece divided by height) must be between 1.3 and 2.5, inclusive. Length and height are defined in 601.1.4.

3.8 Wraps and Closures

An automation-compatible mailpiece may not be polywrapped, polybagged, or shrinkwrapped; have clasps, strings, buttons, or similar closure devices; or have protrusions that might impede or damage the mail or mail processing equipment.

3.9 Staples and Saddle Stitching

Staples or saddle stitching may be used only on booklet-type mailpieces to join the bound edge (spine). Inserted staples or stitching must parallel the bound edge, seat tightly and securely, and have no protrusions that might impede or damage the mail or mail processing equipment.

3.10 Rigid and Odd-Shaped Items

Rigid items (e.g., pens, pencils, keys, bottle caps) are prohibited within mailpieces. Reasonably flexible items (e.g., credit cards) are permitted. Subject to 3.12, Flexibility Standards for Automation Letters, odd-shaped items (e.g., coins and tokens) are permitted if firmly affixed to and wrapped within the contents of the mailpiece and envelope to streamline the shape of the mailpiece for automated processing.

3.11 Tabs, Wafer Seals, Tape, and Glue

Tabs, wafer seals, cellophane tape, or permanent glue (continuous or spot) may be used as applicable to the particular type of mailpiece under 3.14, Self-mailers, Booklets, Postcards, and Heavy Letter Mail, if the sealing devices do not interfere with the recognition of the barcode, price marking, postage information, or delivery or return addresses. In all cases, additional tabs or seals may be used. Cellophane tape is not acceptable within the barcode clear zone. Tabs or wafer seals placed in the barcode clear zone must contain a paper face meeting the standards for background reflectance and, if the barcode is not preprinted by the mailer, the standards for acceptance of water-based ink. Tabs, wafer seals, and tape must have a peel adhesion (shear strength) value of at least 15 ounces/inch at a speed of 12 inches/minute after application to a stainless steel plate; the test is to be conducted 10 minutes after the material is applied to the plate.

3.12 Flexibility Standards for Automation Letters

3.12.1 Machinability

To ensure transport through automated mail processing machines, a mailpiece and its contents must bend easily when subjected to a transport belt tension of 40 pounds around an 11-inch-diameter drum.

3.12.2 USPS Services for Flexibility Testing

A mailer wanting to have mailpieces tested for flexibility must submit at least 50 sample pieces and a written request to USPS Engineering at least 6 weeks before the mailing date. The request must describe mailpiece contents and construction, number of pieces being produced, and preparation level (e.g., presort). Engineering advises the mailer by letter of its findings. If the mailpiece is approved, the letter includes a unique number identifying the piece tested and serves as evidence that the piece meets the relevant standards. A copy of the letter must be attached to each postage statement submitted for mailings of the approved piece. If requested by the USPS, the mailer must show that pieces presented for mailing are the same as those tested and approved.

3.13 Standards for Labels and Stickers Affixed to the Outside of an Envelope

3.13.1 Using Labels and Stickers

Permanent labels and stickers (those designed not to be removed or relocated) must be affixed directly to the outside of the mailpiece with permanent adhesive. A mailer may provide recipients with relocatable labels to place on the outside of response pieces sent back to the mailer. On pieces mailed at First-Class Mail card prices or at Periodicals prices, labels and stickers may be used only if permitted by the applicable standards.

3.13.2 Pressure-Sensitive Label

Any pressure-sensitive label or sticker affixed directly to a mailpiece before mailing must have a minimum peel adhesion to stainless steel of 8 ounces/inch. This standard does not apply to pressure-sensitive labels provided by the USPS to label bundles to sortation levels.

3.13.3 "Sandwich" Label

A face stock/liner label ("sandwich" label) is a two-part unit with a face stock (top label) attached to a liner (bottom label) affixed to the mailpiece. The face stock must have a peel adhesion value of at least 2 ounces/inch with respect to the liner label and at least 8 ounces/inch when reapplied to stainless steel.

3.14 Self-mailers, Booklets, Postcards, and Heavy Letter Mail

3.14.1 Folded Self-Mailer

Except as noted in 3.14.1c, a folded self-mailer must be prepared with the folded edge parallel to the longest dimension and the address of the mailpiece. Based on the number of tabs used, these additional standards apply:

a. With one tab or wafer seal, the folded edge must be at the bottom of the self-mailer. The tab or wafer seal must be placed in the middle of the top edge of the piece. If formed of a single folded sheet, the self-mailer must be prepared from paper with a minimum basis weight of 28 pounds (measured weight for 500 17- by 22-inch sheets) or 70 pounds (measured weight for 500 25- by 38-inch sheets). If formed of multiple folded sheets, the self-mailer must be prepared from paper with a minimum basis weight of 24 pounds (measured weight for 500 17- by 22-inch sheets) or 60 pounds (measured weight for 500 25- by 38-inch sheets).

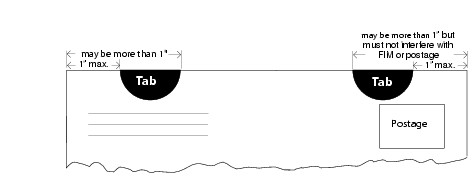

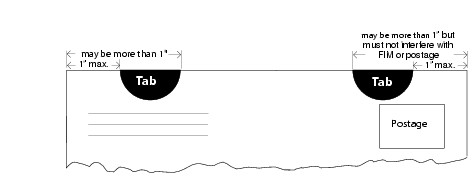

b. With two tabs or wafer seals, the folded edge may be at the top or bottom of the self-mailer. The two tabs or wafer seals must be placed on the open edge, opposite the folded edge. One tab or wafer seal must be placed within 1 inch of the left edge of the piece; the other, within 1 inch of the right edge of the piece. See Exhibit 3.14.1b. The whole tab need not be placed within 1 inch of the edge. The tabs must not obscure the FIM, postage, or required address information. The folded self-mailer must be prepared from paper with a minimum basis weight of 20 pounds (measured weight for 500 17- by 22-inch sheets).

Exhibit 3.14.1b Sealing the Top Edge With Fold at the Bottom

c. In specifically identified formats, a self-mailer may have the final fold on the right side (leading edge) of the piece. The left edge (trailing edge) and other open edges must be secured with at least one tab or a glue line. The number of tabs required is determined by the final trim size and paper basis weight of the piece. If the piece is 7 inches long or more, the piece must be sealed on the top and the bottom. In all cases, additional tabs, seals, or glue spots or glue lines may be used. Newsprint paper is acceptable if the basis weight of the paper meets the minimum standards in 3.14.1a and the piece is certified by the USPS mailpiece design analyst to be acceptable for automated processing.

3.14.2 Booklets

A booklet-type piece must meet these standards:

a. The front and back covers must be prepared from paper with a minimum basis weight of 20 pounds (measured weight for 500 17� by 22-inch sheets).

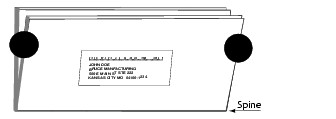

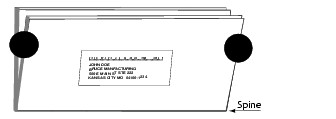

b. Except as noted in 3.14.2d, the bound edge (spine) must be the longest edge of the piece and at the bottom, parallel to the address.

c. The unbound edge (top) must be secured with at least two tabs or wafer seals. One tab or wafer seal must be placed within 1 inch of the left edge of the piece; the second tab or seal, within 1 inch of the right edge of the piece. As an alternative, one tab or wafer seal must be placed within 1 inch from the top left side (trailing edge) of the piece; the second tab or seal, within 1 inch from the top right side (leading edge) of the piece. See Exhibit 3.14.2c.

Exhibit 3.14.2c Alternative Sealing for Booklet With Spine on the Bottom

d. In specifically identified formats, prepared with a minimum paper basis weight of 24-pound bond paper, the spine may be on the shorter side (leading edge) of the piece. The address must still be parallel to the longest side of the piece. The unbound edges must be secured with at least two tabs or wafer seals. If the outside covers are prepared with a minimum paper basis weight of 20-pound bond or equivalent, the spine may be on the right side (leading edge) of the piece. The address must still be parallel to the longest side of the piece. The following restrictions apply:

1. If the final trim size of the piece is no more than 4-1/4 inches high and no more than 6 inches long, the unbound left edges must be secured with at least one tab or wafer seal placed at the vertical center of the piece.

2. If the final trim size of the piece is more than 4-1/4 inches high or more than 6 inches long, the unbound left edge must be secured with two tabs or wafer seals placed within 1 inch of the top and bottom edges.

3.14.3 Postcard

Any postcard must be prepared from paper stock meeting the industry standard for a basis weight of 75 pounds or greater, with none less than 71.25 pounds (measured weight for 500 25- by 38-inch sheets). The stock must be free from groundwood unless coated with a substance adding to the stock's ability to resist an applied bending force. A double postcard not prepared with all edges sealed must have the folded edge at the top or bottom, and the open edge parallel to the address must be secured with one tab (or other permitted closure) in the middle of the length. Pieces claimed at First-Class Mail automation card prices also must meet the standards in 1.2, Physical Standards for Cards Claimed at Card Prices.

3.14.4 Heavy Letter Mail

Heavy letter mail (barcoded letter-size mail weighing more than 3 ounces) must have a barcode in the address block (see 202.5.0, Barcode Placement) and must be prepared in a sealed envelope. Heavy letter mail may neither contain stiff enclosures nor be prepared as a self-mailer or booklet-type mailpiece.

3.15 Enclosed Reply Cards and Envelopes

3.15.1 Basic Standard

All letter-size reply cards and envelopes (business reply mail (BRM), courtesy reply mail (CRM), and meter reply mail (MRM)) provided as enclosures in automation First-Class Mail, Periodicals, and Standard Mail and addressed for return to a domestic delivery address must meet the applicable standards for automation-compatible mail in 3.0. The mailer's signature on the postage statement certifies that this standard, and the standards listed below, have been met when the corresponding mail is presented to the USPS:

a. Each reply piece must include the appropriate facing identification mark (FIM) under 708.9.0, Facing Identification Mark (FIM).

b. Each BRM piece must bear the correct BRM ZIP+4 barcode; each MRM and CRM piece must bear the correct barcode for the delivery address, subject to 202.5.0, Barcode Placement.

c. Each BRM piece must meet any applicable standard under 507.9.0; each MRM piece must meet any applicable standard under 604.4.0, Postage Meters and PC Postage Products ("Postage Evidencing Systems"); and each CRM piece as defined in 3.15.2 must meet the standards of this section.

3.15.2 Courtesy Reply Mail (CRM)

For these standards, courtesy reply mail (CRM) is reply mail other than BRM or MRM enclosed in other mail, with or without prepayment of postage, for return to the address on the reply piece. If postage is required, the customer returning the piece affixes the applicable First-Class Mail postage. Each piece must meet the physical standards in 1.0 or 2.0. CRM has no additional required design standards unless enclosed in automation mail.

Back to Top