DMM TOC > 700 Special Standards708 Technical Specifications1.0 Standardized Documentation for First-Class Mail, Periodicals, Standard Mail, and Flat-Size Bound Printed Matter 2.0 Presort Accuracy Validation and Evaluation (PAVE) 3.0 Coding Accuracy Support System (CASS) 4.0 Standards for POSTNET and Intelligent Mail Barcodes 5.0 Standards for Postal Routing Barcodes 6.0 Standards for Barcoded Tray Labels, Sack Labels, and Container Placards 7.0 Optional Endorsement Lines (OELs) 8.0 Carrier Route Information Lines 1.0 Standardized Documentation for First-Class Mail, Periodicals, Standard Mail, and Flat-Size Bound Printed Matter1.1 Basic StandardsFor First-Class Mail, Periodicals, Standard Mail, and Bound Printed Matter, documentation to support mail volume and preparation must be produced by standardized documentation according to this section. Standardized documentation contains the elements described in 1.2 through 1.8, as applicable. Documentation produced by Presort Accuracy Validation and Evaluation (PAVE)-certified or Manifest Analysis and Certification (MAC)-certified software is considered standardized documentation. 1.2 Format and ContentFor First-Class Mail, Periodicals, Standard Mail, and Bound Printed Matter, standardized documentation includes: a. A heading identifying the listing as a "USPS Qualification Report" appearing at the top of each page. The heading must contain these elements: 1. For First-Class Mail and Standard Mail, the name of the mailer and the mailing, a mailing identification code corresponding to the postage statement, the date when the list was processed or the documentation was produced, the class of mail, and either the DMM standard under which the mail was prepared (e.g., 245.7.0 for Standard Mail automation letters) or the type of prices claimed. 2. For Periodicals, each publication number and title corresponding to the postage statement and entry office, the date when the list was processed or the documentation was produced, the class of mail, and either the DMM standard under which the mail was prepared (e.g., 707.24.0 for letter-size barcoded Periodicals) or the type of prices claimed. For publications that are combined or copalletized and represented on the same documentation, list all publication titles and numbers in the header on the first page. c. For mail in trays or sacks, list these required elements: 1. Tray/sack sortation level. Note with an asterisk ("*") all trays containing overflow mail moved into that tray under 235.6.6, 245.5.3 or 245.7.5. 2. Tray/sack destination ZIP Code from top line of tray/sack label except that, for 3-digit carrier routes trays, list the individual 5-digit ZIP Codes in each tray. 3. The number of pieces for each 5-digit ZIP Code in 5-digit/scheme bundles or trays; for each 3-digit ZIP Code in 3-digit/scheme bundles or trays; for each 3-digit/scheme in (A)ADC bundles or trays; for each (A)ADC in mixed (A)ADC bundles or trays (or, for Periodicals, origin mixed ADC trays). Exception: documentation for 3-digit/scheme letters in AADC trays or for AADC letters in mixed AADC trays is not required unless those trays contain overflow mail. For automation letter mailings, the number of pieces in the next higher level tray in lieu of overflow trays if applicable. For ECR letters prepared under 245.6.0, the number of pieces in carrier routes within full trays. For bundled mail, the number of pieces in each bundle level and presort destination. 4. Separate columns with the number of pieces for each price reported in the mailing, and a continuous running total of pieces for each mailing (group information either in ZIP Code order and by sortation level or by sortation level and within each sortation level, by ZIP Code; report trays and sacks on pallets by pallet level and destination; include all information required in 1.2c. for mail in trays or sacks). For pieces prepared in 5-digit scheme bundles, list by 5-digit ZIP Code within each bundle. For pieces prepared in 3-digit scheme bundles, list by 3-digit ZIP Code within the bundle. Periodicals firm bundles may be listed in a separate firm bundle column or in the appropriate column based on container level. 5. The tray identification number and size (1-foot or 2-foot) if available for letter mail in trays. The tray identification number is optional for tray-based automation flats. 6. For all Periodicals mailings, include a separate "Zone" column. If all automation letters for a specific tray, group, or bundle destination are subject to the same zone price or entry discount, show the applicable zone or destination entry discount for those copies using the zone abbreviations in 1.6.3. If automation letters for a bundle or tray destination are for multiple zones, show all zones included (e.g., "3/4/6") or show "Mixed" (or the authorized abbreviation "M") in the "Zone" column. 7. For Periodicals mailings that contain both In-County and Outside-County pieces, the listing may include a separate "Container Charge" and "Bundle Charge" column. Indicate which trays, sacks, and bundles are subject to the container or bundle charges and a total or a running total. d. For bundles on pallets, list these required elements: 2. Pallet destination ZIP Code. 3. For each bundle, the sortation level and number of pieces claimed at each price. Periodicals firm bundles may be listed in a separate firm bundle column or in a column based on container level. 4. Separate columns with the number of pieces for each price reported in the mailing, and a continuous running total of pieces (group information either in ZIP Code order and by sortation level or by sortation level and within each sortation level, by ZIP Code). Document SCF, ADC, or NDC pallets created as a result of bundle reallocation under 705.8.11, 705.8.12, or 705.8.13 by designating the protected pallet with an identifier of "PSCF" (for an SCF pallet), "PADC" (for an ADC pallet), or "PBMC" (for a NDC pallet). These identifiers are required to appear only on the USPS Qualification Report; they are not required on pallet labels or on any other documentation. 5. For mailings of bundles on pallets under 705.12.0 and 705.13.0, provide a separate 5% threshold summary for each logical merged 5-digit scheme pallet and each logical merged 5-digit pallet. 6. For all Periodicals mailings, include a separate "Zone" column. If all copies for a bundle destination are subject to the same zone price or entry discount, show the zone or entry discount for those copies using the abbreviations in 707.17.6.3. If copies for a bundle destination are for multiple zones, show all zones included (e.g., "3/4/6") or show "Mixed" (or "M") in the "Zone" column. Report foreign copies separately. 7. For Periodicals mailings that contain both In-County and Outside-County pieces, the listing may include separate "Container Charge" and "Bundle Charge" columns. Indicate which pallets and bundles are subject to the container or bundle charges and a total or a running total. 8. At the end, a summary report of the number of pieces claimed at each price on each pallet by postage payment method, and the number of pieces and the weight of the mail on each pallet. e. At the end of the documentation, a summary report of the number of pieces mailed at each price for each mailing by postage payment method (and by entry point for drop shipment mailings) and the number of pieces in each mailing. This information must match the information reported on the postage statement(s). For Periodicals mailings, documentation also must provide: 1. A summary of the number of each type of bundle in the mailing and, optionally, the total bundle charge paid. Report only bundles subject to the Outside-County bundle prices under 707.1.1.3. 2. A summary of the number of each type of container in the mailing and, optionally, the total container charge paid. Report only trays, sacks, and pallets subject to the Outside-County container prices under 707.1.1.4. 3. For combined mailings, a summary by mailer of the number of each type of bundle and container in the mailing and, optionally, the bundle and container price paid. Report only bundles, trays, sacks, and pallets subject to the Outside-County bundle and container prices. 4. A summary of the number of copies for each zone, including In-County, DDU, SCF, and ADC prices. A separate summary report is not required if a PAVE-certified postage statement facsimile generated by the presort software used to prepare the documentation is presented for each mailing. 1.3 Price Level Column HeadingsThe actual name of the price level (or corresponding abbreviation) is used for column headings required by 1.2, Format and Content, and shown below: a. Automation First-Class Mail, Standard Mail, and barcoded Periodicals:

b. Presorted First-Class Mail, barcoded and nonbarcoded Periodicals flats, nonbarcoded Periodicals letters, and machinable and nonmachinable Standard Mail:

c. Carrier Route Periodicals and Enhanced Carrier Route Standard Mail:

1.4 Sortation Level[10-5-09] The actual sortation level (or corresponding abbreviation) is used for the bundle, tray, sack, or pallet levels required by 1.2 and shown below:

1.5 Combined, Copalletized, and Merged MailingsFor combined or copalletized mailings of Periodicals and Standard Mail prepared under 705.8.0, 705.10.0, 705.12.0, or 705.13.0, documentation must show this additional information: a. For mailings that require multiple postage statements: 1. A column that identifies the contents of all trays/bundles by product or edition code. 2. Prices for each product or edition shown in the correct "Price" column and summarized for each tray, sack, or pallet and for the entire mailing. b. For Periodicals, when copies of multiple editions or publications are combined in a firm bundle: report "1" in the appropriate "Piece Price" column for one edition or publication, and report "0" in the "Piece Price" and the "Product/Edition Code" columns for the other editions or publications in the firm bundle. c. For large-volume mailing jobs reported on a single listing, the mailer may provide abbreviated documentation that shows full bundle detail for the first 20 pallets/sacks and every twentieth pallet/sack after that. Mailers must maintain full bundle detail (by product or edition code and price) for the entire mailing job for 90 days and provide it to the USPS on request within 3 working days. This documentation must include the price summary by product or edition for each pallet/sack, including those for which full detail bundle listings are not reported. 1.6 Detailed Zone Listing for Periodicals1.6.1 Definition and RetentionThe publisher must be able to present documentation to support the number of copies of each edition of an issue, by entry point, mailed to each zone, and at DDU, DSCF, DADC, DNDC, and In-County prices. This listing is separate from the standardized documentation required to support presort and may be submitted with each mailing, or a publisher may keep these records for 2 months after the mailing date. A publisher must be able to submit detailed zone listings for specific mailings upon request by the USPS. 1.6.2 CharacteristicsReport the number of copies mailed to each 3-digit ZIP Code area using either one of the following formats: a. Report copies by each 3-digit ZIP Code in ascending numeric order. Include columns for: 3-digit ZIP Code, zone, and number of copies per zone. Include a summary of the number of copies at each zone price at the end of the report. A 3-digit ZIP Code may appear more than once if there are copies at different zone prices (e.g., In-County and Outside-County copies) for that 3-digit ZIP Code. b. Report copies by each zone and by 3-digit ZIP Code in ascending numeric order. For each zone, include columns for: 3-digit ZIP Code and number of copies. Include a summary of the total number of copies for each zone at the end of each zone listing. A 3-digit ZIP Code may appear under more than one zone if there are copies at different zone prices for that 3-digit ZIP Code. 1.6.3 Zone AbbreviationsUse the actual price name or the authorized zone abbreviation in the listings in 1.0 and 707.17.6.2:

1.7 Bundle and Container Reports for Outside-County Periodicals MailA mailer must present documentation to support the actual number of bundles and containers of each edition of an issue as explained in 1.7.1 and 1.7.2 below. 1.7.1 Outside-County Bundle ReportThe bundle report must contain, at a minimum, the following elements: a. Container identification number. g. Number of copies by version in the bundle. h. An indicator showing which bundles are subject to the bundle charge. 1.7.2 Outside-County Container ReportThe container report must contain, at a minimum, the following elements: a. Container identification number. d. Container entry level (origin, DDU, DSCF, DADC, or DNDC). e. An indicator showing which containers are subject to the container charge. 1.8 Optional InformationStandardized documentation may include additional information about the pieces mailed (such as individual tray or sack total piece counts, optional identification codes, bundle weights) if this information does not conflict with the information required under 1.2 through 1.7. 2.0 Presort Accuracy Validation and Evaluation (PAVE)2.1 Presort Accuracy Validation and Evaluation (PAVE)2.1.1 Basic InformationThe Presort Accuracy Validation and Evaluation (PAVE) program is a process to evaluate presort software and determine its accuracy in sorting address files under DMM standards. PAVE is available only to software and hardware manufacturers (i.e., companies that develop presort software or manufacture presorting equipment). PAVE certification does not guarantee acceptance of customer mail prepared with PAVE-validated hardware/software. 2.1.2 ProcessPAVE evaluates the accuracy of presort products by providing test address files to vendors. Vendors process the test file(s) through their presort software or hardware and return the resulting postage statement facsimile(s) and other presort documentation to the USPS National Customer Support Center (NCSC) for evaluation of the answers. Each test file is evaluated for its accuracy of presort, compliance with current DMM standards, accuracy of sack/tray/pallet tag labels, and general acceptability of computer-generated facsimiles of postage statements and other presort documentation. If the answers are accurate, the vendor's presort product is validated for a 12-month period or until the end of the current annual period. 2.1.3 ParticipationFor information on participation in PAVE, presort product developers may request the PAVE Program Technical Guide from the NCSC by calling 1-800-238-3150. Participants may use the PAVE form included in that guide to order PAVE test files. 3.0 Coding Accuracy Support System (CASS)3.1 Basic Information3.1.1 PurposeThe Coding Accuracy Support System (CASS) improves the accuracy of delivery point codes, ZIP+4 codes, 5-digit ZIP Codes, and carrier route codes on mailpieces. CASS provides a common platform to measure the quality of address matching software and to diagnose and correct software problems. 3.1.2 RequirementAny mailing claimed at an automation price must be produced from address lists properly matched and coded with CASS-certified address matching methods listed below. A mailer using multiline optical character readers (MLOCRs) to print delivery point barcodes on mailpieces must also obtain CASS certification (including Multiline Accuracy Support System (MASS)) for the address matching software used on the MLOCRs. 3.1.3 MethodsDelivery point or ZIP+4 coding may be obtained by using the CASS-certified DPC address matching software with components DPV and LACSLink; CASS-certified Z4CHANGE process; CASS-certified DirectDPV process; NCOALink; or DSF2 process. 3.2 Software Certification3.2.1 GeneralAny user of address matching software that applies ZIP+4 codes to address lists to obtain an automation price must use address matching software that is CASS-certified. Address matching software used to ZIP+4 code address records must, as part of its process, return a standardized address to ensure that the ZIP+4 code or mailer-applied barcode represents the proper depth of code available. The original input address submitted for coding may also be returned. The CASS-certified address matching software must be used according to specific parameter settings (configurations) as described below. 3.2.2 Software ConfigurationAll address lists used to produce mailings for automation prices must be matched and ZIP+4 coded with current CASS-certified software in line with the configuration standards shown below. Summary output reports or computer-generated facsimile Forms 3553 must contain information about the configuration used when processing the address list on the CASS-certified address matching software. 3.2.3 Permissible ConfigurationsThese are permissible configurations for address matching software: a. Vendor-Supplied Software With Vendor CASS-certified Software Configurations. The software vendor is CASS-certified for specific configurations. The user is using that software as prescribed by the vendor and with the CASS-certified configurations obtained by the vendor. b. Vendor-Supplied Software With User CASS-certified Software Configurations. The software user is using vendor-supplied software in a configuration not CASS-certified by the vendor but by the user. c. User-Developed Software for Which User Obtained CASS Certification. The software user obtained individual user CASS certification for self-developed software and is using it as certified. 3.2.4 UseWhen used for ZIP+4 or delivery point barcoding, the address matching software and coding methods must have a valid CASS certification and use the current USPS ZIP+4 Product updated to include all applicable change transaction files. 3.3 Date of Address Matching and Coding3.3.1 Update StandardsUnless Z4CHANGE or DirectDPV is used, all automation and carrier route mailings bearing addresses coded by any AIS product must be coded with current CASS-certified software and the current USPS database. Coding must be done within 90 days before the mailing date for all carrier route mailings and within 180 days before the mailing date for all non-carrier route automation price mailings. All AIS products may be used immediately on release. New product releases must be included in address matching systems no later than 45 days after the release date. The overlap in dates for product use allows mailers adequate time to install the new data files and test their systems. Mailers are expected to update their systems with the latest data files as soon as practicable and need not wait until the "last permissible use" date. The mailer's signature on the postage statement certifies that this standard has been met when the corresponding mail is presented to the USPS. The "current USPS database" product cycle is defined by the following table.

3.3.2 Z4CHANGE List MatchingWhen using Z4CHANGE to match and code address lists for automation price mailings: a. The entire address list must first be matched and ZIP+4 coded with current CASS-certified software and the current USPS ZIP+4 Product. b. Every 60 days after the first matching, the address list must be processed through Z4CHANGE using USPS-certified software to identify changed records since the last update. c. The changed records identified through the Z4CHANGE processing must then be matched and coded using current CASS-certified address matching software and the current ZIP+4 Product. d. The entire address list must be rematched and ZIP+4 coded every 3 years using current CASS-certified software and the current USPS ZIP+4 Product. 3.3.3 DirectDPV List MatchingWhen using DirectDPV to match and code address lists for automation price mailings: a. The entire address list must first be matched and ZIP+4 coded with Cycle L (or later) CASS-certified software and the current USPS ZIP+4 product. b. Every 180 days after the initial matching, the address list must be processed through DirectDPV using Cycle L (or later) CASS-certified address matching software to identify changed records since the last update. c. If an address record was previously ZIP+4 coded and that ZIP+4 code is not in DirectDPV, it does not need to be run through CASS-certified address matching software until the annual run. Address records identified as changed through DirectDPV that have a valid converted 11-digit record require additional processing. These records can either be reconstructed using the 11-digit code provided or reprocessed through CASS-certified software. Address records identified as changed through DirectDPV that have a zero 11-digit code must then be matched and coded using Cycle L (or later) CASS-certified address matching software and the current USPS ZIP+4 product. d. The entire address list must be processed once a year using current CASS-certified address matching software and the current USPS ZIP+4 product. 3.4 Definitions—Mailing and Address ListsFor this section, mailing list or address list is the group of names and addresses to which mailpieces in the corresponding mailing are addressed. Whether the addresses used in a mailing are obtained from a single list or from two or more lists (whole lists or extracts of those lists), each list used to produce a mailing claimed at an automation price must meet the standards in 3.0. 3.5 Documentation3.5.1 Form 3553Unless excepted by standard, the mailer must complete a Form 3553 for each mailing claimed at all automation prices and all carrier route prices. A computer-generated facsimile may be used if it contains the required data elements in a format similar to the USPS form. The data recorded on Form 3553 must refer only to the address list used to produce the mailing with which it is presented. The postage statement must be annotated in the block(s) provided to reflect the date when address matching and coding were performed. When a mailing is produced using multiple lists, the mailer must show the earliest (oldest) date of address matching and coding (shown on Form 3553, section B2). The mailer certifies compliance with this standard when signing the corresponding postage statement. 3.5.2 Retention PeriodForm 3553 and other documentation must be retained by the mailer or the mailer's agent for 1 year from the date of mailing and be made available to the USPS on 24-hour notice. 3.5.3 Using Output InformationThe data recorded on Form 3553 is taken from the summary output report generated by the computer process by which address lists are matched and ZIP+4 coded using CASS-certified software. The summary output information may also be generated as a facsimile Form 3553. Form 3553 may show summary output information for a single address list or consolidate summary output information from multiple address lists combined to produce a single mailing. Figures on Form 3553 are not required to match total mailpiece figures on the corresponding postage statement. 3.5.4 Providing Required DataSummary output reports or computer-generated Forms 3553 must contain this information: a. CASS-certified company name as it appears on the CASS certificate; name and software version that received CASS certification; and the software configuration used when processing the address list. b. Name of the list processor using the CASS-certified software to match and code the address list, the date the address list was processed, the date of the USPS database used to code the address list, the address list name or identification number, the total number of address records on the list submitted for coding, the total number of address records successfully coded to the appropriate depth of code, and the valid dates for the records successfully coded. 3.5.5 Using a Single ListWhen a mailing is produced using all or part of a single address list, the mailer must retain one Form 3553 and other required documentation reflecting the summary output information for the entire list, as obtained when the list was coded. When the same address list is used for other mailings within 180 days of the date it was matched and coded, a copy of the Form 3553 must be retained with the documentation for each mailing. 3.5.6 Using Multiple ListsWhen a mailing is produced using multiple address lists, the mailer must retain a consolidated Form 3553 summarizing the individual summary output and/or facsimile Forms 3553 for each list used (and other required documentation). As an alternative, the mailer may combine the addresses selected from the multiple lists into a single new list, reprocess the addresses using CASS-certified address matching software, and retain one Form 3553 for the summary output generated by that process. 3.5.7 Using CASS CertificateIf the name of the CASS-certified company entered on Form 3553 does not appear on the list published by the USPS, a copy of the CASS certificate for the software used also must be retained by the mailer with the documentation. 3.6 CASS Certification3.6.1 Testing ArrangementsTo obtain information on standards and arrange for testing of carrier route, ZIP+4, or delivery point address matching software, contact the National Customer Support Center by calling 1-800-238-3150, or by writing to the CASS Certification Department, National Customer Support Center (see 608.8.0 for address). 3.6.2 CASS Stage IThe CASS certification process is a two-stage procedure. Stage I is a test file with answers supplied on request to customers wanting to certify an address matching software product. The Stage I file contains fabricated sample addresses from address ranges across the country with missing or incorrect address elements. The correct answers supplied on this Stage I test file allow self-assessment of address matching software/hardware accuracy so that software/hardware vendors or users can predetermine product readiness for the actual test. 3.6.3 CASS Stage IIThe Stage II file is the actual test without answers. This test measures the accuracy of address matching software/hardware. Similar to the Stage I file, the Stage II file contains fabricated sample addresses from address ranges across the country with missing or incorrect address elements that the address matching software must correct. Software vendors or users process the Stage II file against their address matching products, appending the correct or missing information in each address record. After completing the test, the vendor or user returns the Stage II file to the USPS for analysis, scoring, and, if qualified, certification. For multiline optical character readers (MLOCRs) and encoding stations, CASS certification is obtained by barcoding sample mailpieces in a test deck. After completing the test, the vendor or user returns the test deck to the USPS for analysis, scoring, and, if qualified, certification. 3.6.4 Certification Standardsa. Delivery point code address matching software/hardware must correctly ZIP+4 code the addresses in the Stage II file or test deck with an accuracy rate determined by the CASS Certification Department and must correctly append the additional two digits of the delivery point code (plus a check digit) to the Stage II file or test deck with 100% accuracy. b. A 2-digit utility (separate or stand-alone address matching software that appends only the correct 2-digit DP9019C information) must use the standardized address information returned by DPC address matching software when determining the correct delivery point code. A 2-digit utility must assign the 2-digit delivery point code (plus a check digit) to the addresses in the Stage II file with 100% accuracy. c. Address matching software used to assign 5-digit ZIP Codes and carrier route codes must assign the appropriate codes to the Stage II file with an accuracy rate determined by the CASS Certification Department. 3.6.5 Customer NotificationThe USPS sends written notice informing the customer of the results of the analysis and the product certification status. Follow-up notification is mailed to remind previously certified vendors and users of the next certification. 4.0 Standards for POSTNET and Intelligent Mail Barcodes4.1 GeneralPOSTNET (Postal Numeric Encoding Technique) and Intelligent Mail barcodes are USPS-developed methods to encode ZIP Code information on mail that can be read for sorting by automated machines. Intelligent Mail barcodes also encode other tracking information. 4.2 POSTNET Barcode4.2.1 GeneralPOSTNET (Postal Numeric Encoding Technique) is the USPS-developed barcode method to encode ZIP Code information on mail that can be read for sorting by automated machines. A POSTNET barcode can represent a 5-digit ZIP Code (32 bars), a 9-digit ZIP+4 code (52 bars), or an 11-digit delivery point code (62 bars). The information content of the barcode is based on the combination of tall (full) bars and short (half) bars. A tall bar represents "1," and a short bar represents "0." When separated into groups of five, these bars sequentially represent each of the digits of the ZIP Code (or ZIP+4 code or delivery point code) for the delivery address, plus an additional digit designated as the correction digit. The correction digit is derived from adding the numbers in the ZIP Code (or ZIP+4 or delivery point code) and determining which single-digit number must be added to that sum to make the total a multiple of 10. The first and last bars of the barcode are frame bars and must always be full bars. 4.2.2 5-Digit BarcodeA 5-digit barcode is a single field of 32 bars consisting of a frame bar, a series of 25 bars that represent the correct 5-digit ZIP Code for the address on the piece, 5 bars that represent the correction digit, and a final frame bar. 4.2.3 ZIP+4 BarcodeA ZIP+4 barcode is a single field of 52 bars consisting of a frame bar, a series of 45 bars that represent the correct ZIP+4 code for the address on the piece, 5 bars that represent the correction digit, and a final frame bar. 4.2.4 Delivery Point BarcodeA delivery point barcode (DPBC) is formed by adding 10 bars (representing two additional digits) to the ZIP+4 barcode. The correct DPBC must be derived from a CASS-certified delivery point code address matching process. To obtain information on the rules for delivery point code calculation, contact the National Customer Support Center by calling (toll-free) 1-800-642-2914, or by writing to CASS/ZIP+4 Matching, National Customer Support Center (see 608.8.0 for address). The following unique codes are also valid DPBCs: a. For a firm (unique) 5-digit ZIP Code, the correct DPBC represents the 5-digit ZIP Code: either the USPS-assigned -0001 or (if the customer assigns four-digit add-ons to internal separations) the correct four digits applicable to the point of delivery, followed by the last two digits of the primary street number, Post Office box number, or rural/highway contract route box number derived from the standardized address returned by the CASS-certified ZIP+4 or delivery point code address matching process. b. For an individual (unique) ZIP+4 code assigned to a business customer, the correct DPBC represents the ZIP+4 code followed by the last two digits of the primary street number derived from the standardized address returned by the CASS-certified ZIP+4 or delivery point address matching process. 4.2.5 POSTNET Barcode Dimensions and SpacingPOSTNET barcodes are subject to these standards for bar dimensions and spacing. Extraneous ink or ink voids must not cause any bar to fail to meet these standards: a. A full bar must be 0.125 �0.010 inch high. b. A half bar must be 0.050 �0.010 inch high. c. All bars must be 0.020 �0.005 inch wide. d. Measured over any 1/2 inch, horizontal spacing of the bars must be 22 �2 bars per inch, and pitch (a bar and a space) must average at least 0.0416 inch but no more than 0.05 inch. The clear vertical space between bars must not be less than 0.012 inch or more than 0.04 inch. 4.3 Intelligent Mail Barcodes4.3.1 Definition[9-8-09] An Intelligent Mail barcode is the USPS-developed barcode that mailers use to encode routing and tracking information on mail that can be read by automated mail processing equipment to sort mail and to provide tracking information to the mailers. An Intelligent Mail barcode consists of 65 vertical bars, each representing one of four possible states: full bar, ascender, tracker, and descender. These 65 bars encode a string of 31 digits, divided into two parts: a 20-digit tracking code and an 11-digit routing code (when required). The 11-digit routing code may contain a ZIP Code, a ZIP+4 code, or a delivery point code, unless required to contain a certain level of code in specific applications; no correction digit is needed within an Intelligent Mail barcode. Mailers may use Intelligent Mail barcodes as follows: a. When used on letters for automation-price eligibility purposes, the routing code must contain a delivery point code that accurately matches the delivery address. b. When used on flat-size pieces for automation-price eligibility purposes, the barcode must contain a delivery point routing code that accurately matches the delivery address. When flat-size pieces bear an Intelligent Mail barcode for automation price eligibility, the barcode on a piece that contains an optional endorsement line (OEL) must contain OEL coding that includes information in Exhibit 7.1.1 corresponding to the correct sortation level of each bundle. The OEL information in the Intelligent Mail barcode is required in addition to a physical OEL. See the Intelligent Mail Barcode Resource Guide available at http://ribbs.usps.gov/ for more information on incorporating OELs in Intelligent Mail barcodes. c. Reply mail pieces using origin Confirm Service do not require a Mailer ID to be encoded into the Mailer Identifier field. All other mailpieces, including QBRM letters and PRM pieces as of May 2011, bearing Intelligent Mail barcodes must include the Mailer ID in the Mailer Identifier field. Confirm subscribers approved for OneCode Confirm must incorporate their Confirm Subscriber ID (which is their MID) when using Intelligent Mail barcodes. OneCode Confirm subscribers can contact Confirm Customer Assistance at 1-800-238-3150 or refer to Publication 197 for specific instructions. Mailers printing the Intelligent Mail barcode solely for automation price eligibility can contact the PostalOne! Help Desk at 1-800-522-9085 to obtain a MID. 4.3.2 SpecificationsComplete specifications for Intelligent Mail barcodes are defined in USPS publication USPS-B-3200.This publication also provides details on how to encode the routing code and tracking code into an Intelligent Mail barcode, barcode dimensions and spacing, clear zone, skew and rotation tolerance, and print characteristics. The assignment of a Barcode Identifier, Service Type Identifier, and Mailer ID are described by the respective publications for each extra service. These publications are available at http://ribbs.usps.gov/. 4.4 Reflectance4.4.1 Background ReflectanceA background reflectance of at least 50% in the red portion and 45% in the green portion of the optical spectrum must be produced in the following locations when measured with a USPS or USPS-licensed envelope reflectance meter: a. The barcode clear zone of a card-size or a letter-size piece barcoded in the lower right corner. b. The area surrounding the barcode (within 1/8 inch of the leftmost and rightmost bars and 1/25 inch above and below the barcode) of a card-size, letter-size, or flat-size piece barcoded in the address block and of a flat-size, First-Class Mail parcel, or Not-Flat Machinable piece barcoded elsewhere. 4.4.2 Print Reflectance DifferenceA print reflectance difference (PRD) of at least 30% in the red and green portions of the optical spectrum is required between the background material of the mailpiece and the barcode, when measured with a USPS or USPS-licensed envelope reflectance meter. (PRD equals the reflectance of the background minus the reflectance of the ink.) 4.4.3 OpacityThe material on which the barcode appears must have enough opacity to prevent printing from "showing through" to the extent that it interferes with postal equipment that reads the barcode. The print contrast ratio (PCR) of print (other than the barcode) that shows through the barcode clear zone or the barcode area in the address block must not exceed 15% when measured in the red and green portions of the optical spectrum. 4.4.4 Dark Fibers and Background PatternsDark fibers or background patterns that produce a print contrast ratio of more than 15% when measured in the red and green portions of the optical spectrum are prohibited in these locations: a. The area of the address block or the barcode clear zone where the barcode appears on a card-size or a letter-size piece mailed at automation prices or at Enhanced Carrier Route saturation or high density prices. b. The area of the address block or the area of the mailpiece where the barcode appears on a flat-size piece in an automation price mailing or on a First-Class Mail parcel or a Not Flat-Machinable piece. 4.5 Skew and Baseline Shift4.5.1 Card-Size and Letter-Size PiecesFor a barcode on a card-size or a letter-size piece, the combined effects of positional skew (slant or tilt of the entire barcode baseline) and rotational skew (slant or tilt of the individual barcode bars) must be limited to a maximum rotation of the bars of �5 degrees from a perpendicular to the bottom edge of the piece. The individual bars of a barcode must not shift (be vertically offset) more than 0.015 inch from the average baseline of the barcode. For information on barcode placement for card-size and letter-size pieces, see 202.5.0. 4.5.2 Flat-Size Pieces, First-Class Mail Parcels, Standard Mail Irregular Parcels, and Not Flat-Machinable PiecesThe maximum rotational skew (slant or tilt of the individual barcode bars) for barcodes is �10 degrees from a perpendicular to the baseline of the barcode. There is no positional skew requirement. The individual bars of a barcode must not shift (be vertically offset) more than 0.015 inch from the average baseline of the barcode. For information on barcode placement for flat-size pieces, see 302.5.0. For information on barcode placement on parcels and Not Flat-Machinable pieces weighing less than 6 ounces, see 402.4.0. 4.6 Barcode Software and Hardware Certification4.6.1 PurposeTo help mailers evaluate the quality of their equipment producing barcodes, the USPS offers optional testing and certification to manufacturers of barcoding software and hardware. Certified barcoding equipment ensures that the equipment can produce dimensionally correct barcodes meeting postal specifications. Certification does not ensure that barcodes produced from that equipment can meet the requirements for automation prices because many other variables in barcode production (e.g., ink color and quality, paper color and contrast, equipment operation and maintenance) affect the quality of the barcodes printed on mailpieces. 4.6.2 Testing ArrangementsManufacturers who want their products tested and mailers who want information on available certified products should contact the National Customer Support Center (see 608.8.0 for address). 5.0 Standards for Postal Routing Barcodes5.1 Basic RequirementsMailers may use a postal routing barcode on parcels and Not Flat-Machinable pieces that meet the applicable eligibility requirements in 433 for First-Class Mail, 443 for Standard Mail, 453 for Parcel Select, 463 for Bound Printed Matter, 473 for Media Mail, or 483 for Library Mail. Each parcel must bear a properly prepared GS1-128 barcode symbology as described in 5.2 that accurately represents the correct ZIP Code or ZIP+4 code of the delivery address. For information on barcode placement for parcels, see 402.4.0. 5.2 Basic Elements of Postal Routing BarcodesGS1-Code128 postal routing barcode data elements include: a. Barcode Type. GS1-128 is the only acceptable barcode and must be printed within Subset C. b. Start Code. Postal routing barcodes must start with a Symbol Start Code, which is not shown in the human-readable text. c. Function One (FNC1). The FNC1 numeric character for GS1-128 follows the symbol start character, is part of the symbology overhead, and is not shown in the human-readable text. d. Application Identifier (AI). The AI for a postal routing barcode is "420" for domestic mail and is not shown in the human-readable text. e. ZIP Code or ZIP+4 Code. Postal routing barcodes must include the 5-digit ZIP Code or ZIP+4 code of the address. Only the 5-digit ZIP Code appears in the human-readable text. f. Check Digit. A check digit must be added at the end of the sequence of numbers to validate the authenticity of the number. GS1-128 postal routing barcodes must utilize a MOD 103 check digit, which is not shown in the human-readable text. g. Stop Code. The GS1-128 postal routing barcode must end with a Symbol Stop Code, which is not shown in the human-readable text.

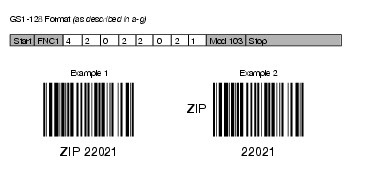

Exhibit 5.2 Postal Routing GS1-128 Barcode Format

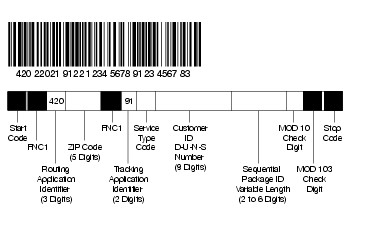

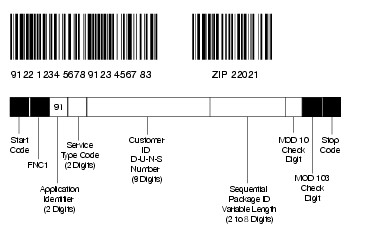

5.3 Use With Delivery Confirmation or Signature Confirmation ServiceEligible machinable parcels may qualify for the barcode discount and bear a Delivery Confirmation or Signature Confirmation barcode using one of the following options: a. The Single Concatenated Barcode (see Exhibit 5.3a). Mailers may place a single concatenated barcode that combines the postal routing information and Delivery Confirmation or Signature Confirmation information. Single concatenated barcodes must be prepared in accordance with the technical specifications and requirements in 503.9.0 for Delivery Confirmation service, 503.10.0 for Signature Confirmation service, and Publication 91, Confirmation Services Technical Guide. If a parcel bears a single concatenated barcode, then no other barcode that contains the postal routing barcode may be affixed to the package.

Exhibit 5.3a Confirmation Services Concatenated GS1-128 Barcode Format

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Enhanced Carrier Route high-density and saturation letter prices |

Letter-size (barcoded labels not required for letter-size pieces with simplified addresses or paid at nonletter prices) |

|---|---|

|

Automation, Presorted, and Enhanced Carrier Route in letter trays under 345.3.0 | |

|

Automation and Presorted in letter trays cotrayed under 705.9.0 using 345.3.0 option | |

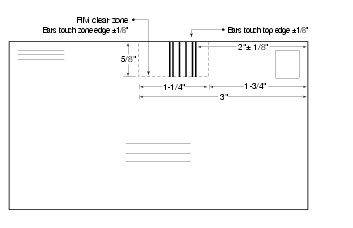

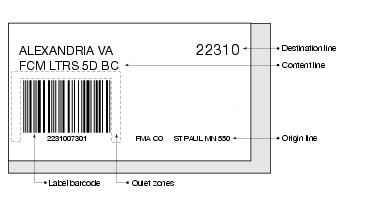

6.2.2 Line 1 (Destination Line)

The destination line must meet these standards:

a. Placement. The destination line must be the top line of the label, placed in the position shown in Exhibit 6.2.2a or Exhibit 6.2.2b (above the barcode on tray labels or 2-inch sack labels and to the right of the barcode on 1-inch sack labels). An exception is that one line of extraneous information may appear above the destination line on tray and sack labels as provided in 6.3.2, and 6.3.2f. The destination line must be completely visible when placed in the label holder. This visibility is ensured if the destination line is no less than 1/8 (0.125) inch below the top of the label when the label is cut and prepared.

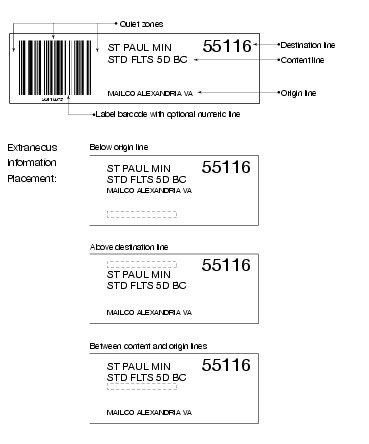

Exhibit 6.2.2a Barcoded 2-Inch Sack Labels and Barcoded Tray Labels

b. Information. The destination line must contain only the information required by the applicable standards for the class, processing category, sortation level of the tray or sack, and the prices claimed. This information is contained in the labeling lists for all sortation and price levels except trays and sacks to carrier route, 5-digit carrier routes, merged 5-digit, and 5-digit destinations, and except for automation letter trays to 5-digit scheme destinations. For the destination line of carrier route, 5-digit carrier routes, merged 5-digit, and 5-digit trays and sacks, the city, two-letter state abbreviation, and 5-digit ZIP Code of the destination 5-digit ZIP Code area must be shown. For 5-digit scheme trays, the city, two-letter state abbreviation, and ZIP Code for the destination scheme must be obtained from the City State Product. The destination line may contain abbreviated city and state information if such abbreviations are those in the City State Product.

Exhibit 6.2.2b Barcoded 1-Inch Sack Labels

c. Overseas Military Mail. The exact content identifier number (CIN) that matches the level of tray or sack must be used in the barcode and barcode numeric line on barcoded tray or sack labels. The required second line of information that corresponds to the CIN must appear on the human-readable content line of the label. The human-readable content line is automatically printed when labels are obtained through the PASSPORT system or ordered on Form 1578-B for printing at the Label Printing Center in Topeka, Kansas. A footnote at the end of the content line information means that the mailer must add appropriate information when ordering and printing tray and sack labels. Any mailer using PASSPORT to order labels must also add the appropriate additional information to the human-readable content line for those content lines marked with a footnote.

6.2.3 Line 2 (Content Line)

The content line must meet these standards:

a. General. The content line must appear directly below the destination line as shown in Exhibit 6.2.2a or Exhibit 6.2.2b . This line must show the class, processing category, and the sortation level of the tray or sack as required by the applicable standards for the mailing. The appropriate content identifier number (CIN) in 6.2.4 that corresponds to that content line must be used in the barcode.

b. Periodicals. Except as provided in 705.8.16 for copalletized mailings and in 707.27.2 for combined mailings, Periodicals publications must use one of the following for Line 2 class information:

2. "NEWS" if published weekly or more often or if authorized newspaper treatment as of March 1, 1984.

c. Additional Information. For 3-digit scheme trays as specified by the labeling list, the content line for some destinations must be followed by the letter "A," "B," or "C," which is not required to be right-justified. For carrier route trays and sacks, the content information must be followed by a one-letter carrier route type description followed by a space and a 3-digit route number for the route to which the tray is destined.

6.2.4 3-Digit Content Identifier Numbers

The exact content identifier number (CIN) that matches the level of tray or sack must be used in the barcode and barcode numeric line on barcoded tray or sack labels. The required second line of information that corresponds to the CIN must appear on the human-readable content line of the label. The human-readable content line is automatically printed when labels are obtained through the PASSPORT system or ordered on Form 1578-B for printing at the Label Printing Center in Topeka, Kansas. A footnote at the end of the content line information means that the mailer must add appropriate information when ordering and printing tray and sack labels. Any mailer using PASSPORT to order labels must also add the appropriate additional information to the human-readable content line for those content lines marked with a footnote. See Exhibit 6.2.4 .

Exhibit 6.2.4 3-Digit Content Identifier Numbers

- This information must be followed by a one-letter carrier route type description, followed by a 3-digit route number for the route to which the tray or sack is destined. At the mailer's option, one space is permitted between the type description and route number.

- This information must be followed by the appropriate scheme letter A, B, or C if applicable for the destination of the tray as indicated in L002, Column B.

6.2.5 Line 3 (Origin Line)

The origin line must appear below the content line in a location appropriate for a tray or sack as shown in Exhibit 6.2.2a or Exhibit 6.2.2b . This line must show the city and state of the entry Post Office or the mailer's name and the city and state of the mailer's location. It is recommended that the mailer's name also appear with the city and state of the entry Post Office. The origin line may contain abbreviated city and state information if such abbreviations are those in the USPS City State Product. A mailer code assigned by the USPS or such words as "Mailer," "From" (or "FR"), or "Entered at" may appear before the required information on this line.

6.3 Additional Standards—Barcoded 2-Inch Sack Labels and Barcoded Tray Labels

6.3.1 Paper Stock, Size, and Color

Barcoded 2-inch sack labels and barcoded tray labels must meet these specifications:

a. Color: white or manila for First-Class Mail and Standard Mail; pink for Periodicals.

b. Reflectance: minimum reflectance requirements in 6.3.3i.

c. Perforations: perforations are not permitted through the barcode and barcode quiet zone on labels.

d. Weight: minimum 70-pound paper stock (500 sheets, 24 by 36 inches).

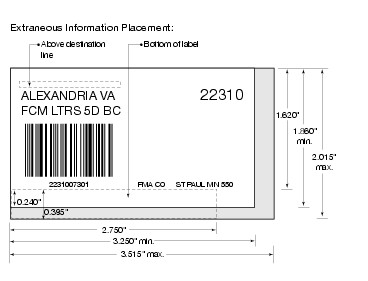

e. Height: 1.860 inches minimum; 2.015 inches maximum.

f. Length: 3.250 inches minimum; 3.515 inches maximum.

g. Thickness: 0.005 inch minimum.

6.3.2 Printed Human-Readable Lines

The printed human-readable text lines must meet these specifications:

a. General. The human-readable lines must be printed in uppercase letters, with no run-on letters or numerals. The letters and numerals in the destination, content, and origin lines must be easy to read. The character spacing can be proportional with respect to the type font used.

b. Destination Line (Line 1). The printed destination line must have a minimum character height of 0.120 inch and a maximum character density of 17 characters per inch. The corresponding ZIP Code must have a minimum character height of 0.190 inch and a maximum character density of 10 characters per inch. The destination line must accommodate at least 21 characters for the destination city and state and any required prefixes, and 5 characters for the ZIP Code. Only the correct 3-digit ZIP Code prefix is to be printed when the required labeling for a tray includes only a 3-digit ZIP Code prefix for Line 1 (trailing zeros are not permitted).

c. Content Line (Line 2). The printed content line must have a minimum character height of 0.120 inch. The content line must accommodate at least 21 characters and have an effective font density of no greater than 17 characters per inch.

d. Origin Line (Line 3). The printed origin line must have a maximum character height of 0.085 inch and must accommodate at least 21 characters.

e. Barcode Numeric Line. The barcode numeric line must consist of a numeric representation of the information contained in the barcode as required by 6.3.3b (5-digit ZIP Code, CIN, processing code). The printed numeric barcode line must have a maximum character height of 0.085 inch, must accommodate 10 characters, and must be placed below the barcode and lower barcode quiet zone as shown in Exhibit 6.2.2a Barcoded 2-Inch Sack Labels and Barcoded Tray Labels.

f. Extraneous Information Lines. Extraneous information may be printed only at the top of the label and/or at the bottom of the label. The preferred location is the bottom of the label. If placed at the bottom of the label, the information must appear only in a rectangular area that begins 1.620 inches from the top of the label and extends to the bottom of the label. Within this lower area, the information may extend 2.75 inches to the right from the left edge of the label. See Exhibit 6.3.2f. Extraneous information at the bottom of the label must appear below the barcode numeric and origin lines. There are no font restrictions for information printed in this area at the bottom of the label with one exception: if information in this area resembles a day of the week or a USPS air stop code it must be in 10-point or smaller type. Extraneous information printed at the top of the label must have a maximum character height of 0.083 inch. Barcodes for a mailer's internal use may not be placed in extraneous information areas or anywhere else on the label, unless approved on a case-by-case test basis by USPS Engineering (see 608.8.0 for address).

Exhibit 6.3.2f Extraneous Information Area

6.3.3 Barcode

The label barcode must meet these specifications:

a. Type of Barcode. The barcode must be an interleaved 2-of-5 code according to the Automatic Identification Manufacturers' Uniform Symbology Specification (AIM/USS-I 2/5) with the exceptions noted below.

b. Information. The barcode must represent three numeric elements:

1. The 5-digit ZIP Code destination of the tray. For a 3-digit tray destination, the 3-digit ZIP Code prefix is followed by two zeros.

2. The applicable 3-digit content identifier number (CIN) for the tray as shown in 6.2.4.

3. A 2-digit USPS processing code on all 2-inch tray labels. A processing code is optional on 2-inch sack labels. Use code "01" for all automation price and machinable letter-size pieces, and for all automation-compatible and cotrayed flat-size pieces. Use code "07" for all other mail, including manual pieces, nonmachinable letter-size pieces, and nonautomation Carrier Route price pieces.

c. Placement. The barcode must be on the left side of the tray label, below the destination and content lines. The top of the barcode must be not less than 0.6 inch from the top of the label. The bottom of the barcode must be no more than 1.5 inches from the top of the label. The barcode must not extend more than 2.0 inches to the right from the left edge of the label.

d. Quiet Zones. Two quiet zones (clear areas) must be maintained, one to the left and one to the right of the barcode, each measuring at least 10 times the X dimension (see 6.3.3f) and extending the full height of the barcode. Two additional quiet zones must be maintained, one above and one below the barcode for its full width, each measuring at least 0.070 inch. The quiet zones must meet the space reflectance specification in 6.3.3i.

e. Height. The height of the barcode must be from 0.65 to 0.75 inch.

f. X Dimension. The width of the narrow bar element and narrow space element is defined as the X dimension. It must be selected as a single dimension and it must be uniform within the barcode. The minimum X dimension or narrow element width is 0.012 inch and the maximum is 0.016 inch. The optimum X dimension or narrow bar/space width is 0.015 inch.

g. Wide-to-Narrow Bar Ratio. The wide-to-narrow ratio for bars and spaces within the barcode must be between 3 to 1 and 2.3 to 1 and uniform within the barcode. The optimum ratio is 3 to 1.

h. Printing Tolerances. The maximum irregularity in the edge straightness of any bar element is 0.3 times the X dimension. The printing tolerance for any (narrow or wide) bar or space is +0.004 inch and is not cumulative. Example 1: If an X dimension of 0.015 inch is selected, each individual narrow bar or narrow space element on the printing of the barcode must not be less than 0.011 inch or more than 0.019 inch. Example 2: If the wide bar/space dimension of 0.045 inch is selected, each individual wide bar or space must not be less than 0.041 inch or more than 0.049 inch.

i. Reflectance. When measured at 633 nanometers, bar reflectance must be less than 30% and space reflectance must be more than 40%. The bar-to-space reflectance difference must be more than 40%.

6.4 Additional Standards—Barcoded 1-Inch Sack Labels

6.4.1 Paper Stock, Size, and Color

Barcoded 1-inch sack labels must meet these specifications:Color: white or manila for First-Class Mail and Standard Mail and Package Services; pink for Periodicals.

a. Reflectance: minimum reflectance requirements in 6.4.3i.

b. Weight: minimum 70-pound paper stock (500 sheets, 24 by 36 inches).

c. Height: 0.937 inch minimum; 0.980 inch maximum.

d. Length (parallel to printing): 3.250 inches minimum; 3.515 inches maximum.

6.4.2 Printed Human-Readable Lines

The printed human-readable text lines must meet these specifications:

a. General. The human-readable lines must be printed in uppercase letters, with no run-on letters or numerals. The letters and numerals in the destination, content, and origin lines must be easy to read. The character spacing can be proportional with respect to the type font used, and should not exceed 17 characters per inch. When the information cannot be shortened by acceptable postal abbreviations, it may be printed in a compressed font. The information must appear to the right of the right barcode quiet zone.

b. Destination Line (Line 1). The printed destination line must have a minimum character height of 0.083 inch. The corresponding ZIP Code must have a minimum character height of 0.111 inch. The destination line must accommodate at least 22 characters.

c. Content Line (Line 2). The printed content line must have a minimum character height of 0.083 inch. The content line must accommodate at least 21 characters.

d. Origin Line (Line 3). The printed origin line must have a minimum character height of 0.083 inch.

e. Barcode Numeric Line. A barcode numeric line is optional. If used, the numeric line must consist of a numeric representation of the eight digits of information contained in the barcode as required by 6.4.3b (5-digit ZIP Code and CIN). The printed numeric barcode line must have a maximum character height of 0.085 inch. It must be placed a minimum of 0.070 inch below the barcode (see Exhibit 6.2.2b Barcoded 1-Inch Sack Labels).

f. Extraneous Information Lines. Extraneous information may be printed only to the right of the right quiet zone if it does not interfere with scanning and sorting by automated equipment. Extraneous information may be placed (1) below the origin line; (2) above the destination line; or (3) either between the content and origin lines or to the right of required information on the origin line, provided that the information does not consist of numerals that resemble a ZIP Code or 3-digit ZIP Code prefix. It is recommended that this information be placed below the origin line. If placed above the destination line, the maximum height of the type is 0.083 inch, and it is further recommended that the information be printed in a size of type much smaller than the size used on the destination line. Extraneous information must not be placed between the destination and content lines.

6.4.3 Barcode

The label barcode must meet these specifications:

a. Type of Barcode. The barcode must be an interleaved 2-of-5 code according to the Automatic Identification Manufacturers' Uniform Symbology Specification (AIM/USS-I 2/5) with the exceptions noted below.

b. Information. The barcode must represent the following information: the 5-digit ZIP Code destination of the sack (for sacks with a 3-digit destination, this is the 3-digit ZIP Code prefix followed by two zeros); and the 3-digit content identifier number (CIN) applicable to the content of the sack in Exhibit 6.2.4, 3-Digit Content Identifier Numbers.

c. Placement. The barcode must be on the left side of the sack label.

d. Quiet Zones. Two quiet zones (clear areas) must be maintained, one to the left and one to the right of the barcode, each measuring at least 10 times the X dimension (see 6.4.3f) and extending the full height of the barcode. The quiet zones must meet the space reflectance specification in 6.4.3i.

e. Height. The height of the barcode must be at least 0.700 inch.

f. X Dimension. The width of the narrow bar element and narrow space element is defined as the X dimension. It must be selected as a single dimension and it must be uniform within the barcode. The minimum X dimension or narrow element width is 0.012 inch and the maximum is 0.016 inch. The optimum X dimension or narrow bar/space width is 0.015 inch.

g. Wide-to-Narrow Bar Ratio. The wide-to-narrow ratio for bars and spaces within the barcode must be between 3 to 1 and 2.3 to 1 and be uniform within the barcode. The optimum ratio is 3 to 1.

h. Printing Tolerances. The maximum irregularity in the edge straightness of any bar element is 0.3 times the X dimension. The printing tolerance for any (narrow or wide) bar or space is +0.004 inch and is not cumulative. Example 1: If an X dimension of 0.015 inch is selected, each individual narrow bar or narrow space element on the printing of the barcode must not be less than 0.011 inch or more than 0.019 inch. Example 2: If the wide bar/space dimension of 0.045 inch is selected, each individual wide bar or space must not be less than 0.041 inch or more than 0.049 inch.

i. Reflectance. When measured at 633 nanometers, bar reflectance must be less than 30% and space reflectance must be more than 40%. The bar-to-space reflectance difference must be more than 40%.

6.5 Intelligent Mail Tray Labels

6.5.1 Definition

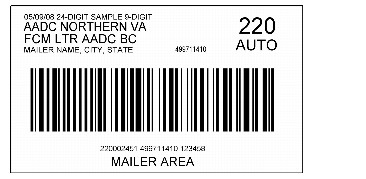

Intelligent Mail tray labels are 2-inch labels used on trays and sacks to provide unique identification within postal processing. 24-digit Intelligent Mail tray labels include only a 24 digit barcode printed in International Symbology Specification (ISS) Code 128 subset C symbology (see Exhibit 6.5.3). To facilitate the transition from 10-digit tray and sack labels to 24-digit barcoded Intelligent Mail tray labels, an optional transitional label is also available. This label includes a 10-digit barcode using the AIM/USS-I 2/5 symbology, in addition to a 24-digit barcode using ISS Code 128 subset C symbology (see Exhibit 6.5.1). Intelligent Mail tray labels also include a human readable field designed to indicate the carrier route for carrier route mailings, display an "AUTO" indicator text for automation mailings, or remain blank for nonautomation mailings. Mailers using Intelligent Mail tray labels may print labels in the 24-digit Intelligent Mail tray label format or the transitional format. Detailed specifications for the tray label and barcode formats are at http://ribbs.usps.gov.

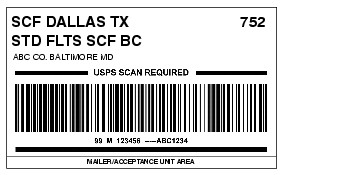

Exhibit 6.5.1 10/24 Transitional Intelligent Mail Tray Label

6.5.2 Transitional Intelligent Mail Tray Label Format

The general format for Intelligent Mail tray labels are as follows:

b. Tray or sack presort destination (postal destination name).

c. Content description, as listed in Exhibit 6.2.4.

d. Office of mailing or mailer information.

f. Carrier route or "AUTO" designation field.

h. 24-digit ISS code 128 subset C barcode numeric line.

i. 10-digit AIM/USS-I 2/5 barcode numeric line.

j. Mailer's area (for mailer-generated information).

6.5.3 24-Digit Intelligent Mail Tray Label

Intelligent Mail tray labels, printed in the 24-digit format, can be used on all trays and sacks to uniquely identify each tray and sack in addition to each mailer or mail preparer. 24-digit Intelligent Mail tray labels bear a single barcode and permit an expanded mailer's use area (see Exhibit 6.5.3).

Exhibit 6.5.3 Intelligent Mail Tray Label

6.5.4 Intelligent Mail Tray Label Format

The core data elements for the Intelligent Mail tray label are as follows:

b. Tray or Sack Destination (Postal destination name).

c. Content Identifier Number (CIN) description (tray or sack content).

d. Office of mailing or mailer information.

e. Destination ZIP Code (the ZIP Code of the trays' or sacks' final destination).

g. Mailer ID (unique identifier of the mailer).

h. 24-digit, ISS Code 128 subset C barcode numeric line.

i. Mailer's Area (set aside for mailer-generated human-readable information).

6.5.5 Barcode Composition

The barcode composition is dependent on the Mailer ID assigned by the USPS. Upon request by the mailer, the USPS assigns a 6-digit or 9-digit Mailer ID based on the demonstrated mail volume of the mailer. Intelligent Mail tray barcodes contain the following elements:

b. Content Identifier Number (CIN), as listed in Exhibit 6.2.4.

c. Processing code, identifying the system or facility generating the label.

e. Serial number, a unique number assigned to each tray or sack.

f. Label type, a default digit.

6.5.6 Unique Serial Number

The Intelligent Mail tray barcode can encode a unique identifier for each tray and sack.

6.5.7 Quality Assurance Provisions

Mailers printing Intelligent Mail tray labels are responsible for the inspection and testing of the labels prior to submission to USPS and for maintaining the overall quality of the labels produced. Inspection and testing of Intelligent Mail tray labels should be performed periodically. Mailers and label vendors are encouraged to submit samples to the National Customer Service Center (NCSC) in Memphis for certification (see 608.8.0 for address).

6.6 Intelligent Mail Container Placards (Labels)

6.6.1 Definition

Mailer-generated container placards bearing Intelligent Mail container barcodes identify pallets and other rolling stock, such as all-purpose containers. Intelligent Mail container barcodes uniquely identify each container and may be scanned at induction points. Detailed specifications for Intelligent Mail container barcodes and placards are available at http://ribbs.usps.gov.

6.6.2 Intelligent Mail Container Placard Configurations

[3-14-10] Intelligent Mail container placards must be affixed on the outside of any shrinkwrap or plastic by self-adhesive or other adhesive means. Placards may be produced in two configurations:

a. Affixed placard measuring at least 8 inches by 11 inches. See 6.6.3 for placard specifications and 6.6.5 placard placement.

b. Optional affixed placard measuring at least 4 inches by 7 inches. See 6.6.6 for placard specifications and 6.6.5 for placard placement.

6.6.3 Intelligent Mail Container Placard Format

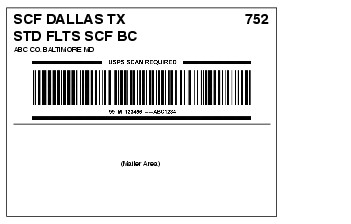

In addition to the general requirements for pallet placards in 705.8.6, Intelligent Mail container placards (see Exhibit 6.6.3) must retain the top one-half of the placard for USPS-required elements. The USPS banner, identification bars, and human-readable text are required elements related to the Intelligent Mail container barcode and will serve as a guide to distinguish the barcode from the other information on the container placard. Required elements include:

a. USPS Banner. "USPS SCAN REQUIRED" must be printed in all uppercase letters centered above the barcode and embedded within the upper identification bar. Clear zone and font size are as follows:

1. A clear zone of at least 0.125 inch, but no more than 0.5 inch, must be maintained between the bottom edge of the text and the top of the barcode.

2. The banner must be printed in a boldface sans-serif font of at least 14-point type.

b. Identification Bars. Horizontal black bars of at least 0.10 inch thick must be printed above and below the barcode. At a minimum, the bars must extend the length of the barcode. Clear zone and other requirements are as follows:

1. The upper bar must be printed at least 0.125 inch above the top edge of the barcode.

2. The upper bar must have a void in the middle sufficient to insert the USPS banner without any element being obscured.

3. The lower bar must be printed at least 0.125 inch below the human-readable representation of the barcode string.

c. Human-Readable Representation of Barcode Data. The human-readable representation of barcode data (text) must be printed in a boldface sans-serif font of at least 12-point type. The text must not exceed the length of the barcode and must be separated by data field. Two blank character spaces must be left between each field. The text must be centered at least 0.125 inch, but no more than 0.25 inch, below the barcode.

d. Barcode Location. The barcode, along with the corresponding USPS banner and identification bars, must be printed on the front side of the pallet placard. When the identification bars extend beyond the length of the barcode, the barcode must be horizontally centered.

e. Minimum size. The minimum size of this placard is 8 inches high by 11 inches long. See additional specifications at http://ribbs.usps.gov. Mailers using larger placards must ensure the barcode conforms to the published specification and the human-readable content is provided as illustrated in Exhibit 6.6.3 and as published on the RIBBS web site.

Exhibit 6.6.3 Intelligent Mail Container Placard

6.6.4 Barcode Format

Intelligent Mail container barcodes are 21 characters in length and contain a USPS-assigned Mailer ID. The format depends on the Mailer ID assigned. Intelligent Mail container barcodes contain the following elements:

a. Application identifier, identifying the source of the barcode.

b. Type indicator, identifying internal or external label generation.

d. Serial number, a unique number assigned to each container.

6.6.5 Placard Requirements

[3-14-10] Mailers may use placards bearing Intelligent Mail container barcodes only under the following conditions:

a. Two placards must be placed on each pallet, one on each adjacent side. Placards must be affixed by self-adhesive or other adhesive means that will not obscure any required element of the placard and remain secure throughout USPS processing.

b. One placard must be placed in the designated area on other USPS containers.

c. Placards affixed to pallets containing Periodicals mail must be pink, except under 6.6.5d or 6.6.5e.

d. Placards prepared in the optional smaller format under 6.6 may be white, but must include a vertical pink 1/2-inch wide identification bar along the left-hand side of the placard, unless prepared under 6.6.5e.

e. Placards containing Periodicals may be all white when used in conjunction with a pink designator label meeting the following criteria:

1. Designator labels must be printed in landscape orientation and must not include any print or graphics other than the required marking in 6.6.5e2.

2. Designator labels must meet or exceed both the horizontal and vertical dimensions of the accompanying Intelligent Mail container placard and must bear only a "PERIODICALS" or "NEWS" marking at least 1/2-inch high (or at least 48-point type).

3. Designator labels may be affixed on the outside of, or be placed beneath, any shrinkwrap or plastic, but must be immediately adjacent to the Intelligent Mail container placard.

4. When using this option, each Intelligent Mail container placard must be accompanied by an adjacent designator label.

6.6.6 Optional Smaller Placard Format

[3-14-10] Mailers may prepare placards bearing Intelligent Mail container barcodes (see Exhibit 6.6.6) in a smaller alternate format as follows:

a. Placards must include the required elements described in 705.8.6.

b. Placards must measure no less than 4 inches high by 7 inches long.

c. Placards prepared in the minimum size of 4 inches high by 7 inches long may include a restricted mailer/acceptance unit area that cannot exceed one line of text or contain print no larger than 12 point. Text in the restricted mailer/acceptance unit area must be restricted to the bottom line of the placard (below the lower barcode identification bar).

d. Intelligent Mail container placards prepared in the optional smaller format, but measuring more than 4 inches high by 7 inches long in both (or either) dimensions, must preserve the top 3.75 inches of the placard, or the area including and above the lower barcode identification bar (whichever is greater), for USPS-required elements. The remainder of the placard is available for restricted mailer/acceptance unit use. Text in the restricted mailer/acceptance unit area, when used, must contain print no larger than 12 point.

e. All text placed in the mailer/acceptance unit area must be approved by the business mail entry unit (BMEU) servicing the mailer for acceptance and verification.

f. Mailers wishing to include additional information other than that approved for use in the defined "mailer/acceptance unit area" must use the larger size placard specified in 6.6.3.

g. Placards must be securely affixed on two adjacent sides on the outside of the shrinkwrap or plastic of pallets.

h. Placards containing Intelligent Mail container barcodes must meet the specifications for placards posted at http://ribbs.usps.gov.

Exhibit 6.6.6 Intelligent Mail Container Placard—Optional Format with Restricted Mailer Area

6.6.7 Unique Barcode Requirement

The Intelligent Mail container barcode can encode a unique identifier for each container. Mailers must ensure that serial numbers in barcodes remain unique for 45 days.

6.6.8 Quality Assurance Provisions

Mailers printing Intelligent Mail container placards are responsible for the inspection and testing of the placards prior to submission to the USPS and for maintaining the overall quality of the placards they produce. Inspection and testing of Intelligent Mail container placards should be performed periodically. Mailers are encouraged to work with their local mailpiece design analyst to validate the accuracy and quality of their placards.

7.0 Optional Endorsement Lines (OELs)

7.1 OEL Use

7.1.1 Basic Standards

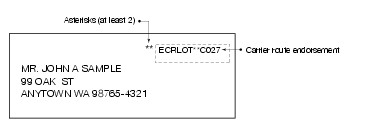

An optional endorsement line (OEL) may be used to label bundles instead of applying pressure-sensitive bundle labels or facing slips to the top piece of bundles. The OEL must show carrier route information or the type of bundle and ZIP Code information as shown in Exhibit 7.1.1, OEL Formats. Use of OELs on bundles is subject to the standards for the price claimed. At the mailer's option, pieces in trays of noncarrier route automation letter-size mail may bear OEL information that corresponds to the sortation level of the tray in which the pieces are placed. The ZIP Code for use on OELs must include the 3-digit ZIP Code prefix or 5-digit ZIP Code as required.

7.1.2 Intelligent Mail Barcodes

When flat-size pieces bear an Intelligent Mail barcode (under 4.3) for automation-price eligibility purposes, the barcode on a piece that contains an optional endorsement line (OEL) must contain OEL coding that includes information in Exhibit 708.7.1.1 that corresponds to the correct sortation level of each bundle. The OEL information in the Intelligent Mail barcode is required in addition to a physical OEL. See the Intelligent Mail Barcode Resource Guide available at http://ribbs.usps.gov/ for more information on incorporating OELs in Intelligent Mail barcodes.

7.1.3 Keyline

A mailer's keyline or comparable information may not be placed on the same line as the OEL or on the line above the OEL. A keyline used on valid ACS mailpieces is subject also to 7.2.4, No ACS Code in OEL.

7.1.4 Firm Bundles

On a firm bundle of carrier route presorted Periodicals, "FIRM" may precede "CAR-RT SORT" in the carrier route information line under 6.0.

7.1.5 Price Markings

At the mailer's option, price markings required by the standards for the price claimed may be included in the OEL if the OEL appears on each piece in the mailing and if it remains a single line with the basic bundle label information (required by 7.1.1) at the right end (e.g., on a carrier route bundle of Enhanced Carrier Route Saturation Standard Mail: * * * * ECRWSS**C-001; on an automation Standard Mail 3-digit bundle: * * * * AUTO**3-DIGIT 750).

7.1.6 Exceptional Address Format

The exceptional address format may appear above the OEL as specified in 602.3.0, Use of Alternative Addressing.

7.1.7 OEL With LOT Information

At the mailer's option, line-of-travel (LOT) information for carrier route Periodicals and Enhanced Carrier Route Standard Mail may be included in the OEL using the applicable format in 7.1.1. All other OEL requirements apply. If there is insufficient space within the OEL to include any other information required (e.g., ACS participant code), this OEL format may not be used.

7.2 OEL Format

7.2.1 Presort Identification

Except when an address block barcode is placed above the optional endorsement line (OEL), the appropriate presort identification must be the first line at the top of the address block or label. A mailer receiving address corrections through Address Change Service (ACS) may use the first eight positions on the left side of the OEL for an ACS human-readable participant code.

7.2.2 Style and Size of Type

The information in the OEL must be in capital letters with letter size and line spacing no less than the size and line spacing of the largest letters or characters in the address block or any part of the address label. Letters in the endorsement line must be the same type font as those in the address block. Only capital letters of the alphabet, Arabic numerals, or asterisks may be used in the OEL.

7.2.3 ACS Code in OEL

If an ACS human-readable participant code (see 507.4.2) is used in an OEL on a label or in an address block, the delimiter symbol (#) must be in the first position at the left margin of the OEL, followed by the seven-character USPS-assigned ACS participant code, then one blank space. The remaining blank spaces between the left-justified delimiter and ACS participant code and the first character of the right-justified mail sortation information of the OEL must be filled with asterisks.

7.2.4 No ACS Code in OEL

If an ACS human-readable participant code is not placed in the OEL as permitted by 507.4.2.4, the OEL must be filled with asterisks from the left margin of the label or address block up to the first character in the OEL. A keyline prepared under 7.1.3 is required on valid ACS mailpieces if an ACS participant wants to receive notification of nondelivery information under 507.1.4.1 in addition to address correction service.

7.2.5 ZIP Code Information

Except for carrier route bundles, the OEL must include the ZIP Code information (5-digit ZIP Code or 3-digit ZIP Code prefix) determined by the sortation level and, when applicable, by the labeling list designated in Exhibit 7.2.5 for ADC, mixed ADC, AADC, or mixed AADC sortation levels. Carrier route OELs must show carrier route information as specified in 8.2.

Exhibit 7.2.5 OEL Labeling Lists

| Periodicals 1 | ||

|---|---|---|

|

L011 2 |

||

| Standard Mail 1 | ||

|

L011 2 |

||

|

L011 2 |

||

| Bound Printed Matter 1 | ||

|

L004 2 |

||

|

L004 2 |

||

8.0 Carrier Route Information Lines

8.1 Basic Information