Overview

1.0 Physical Standards for Machinable Letters and Cards

2.0 Physical Standards for Nonmachinable Letters

3.0 Physical Standards for Machinable and Automation Letters and Cards

4.0 Physical Standards for Flats

5.0 Physical Standards for Nonautomation Flats

6.0 Physical Standards for Automation Flats

7.0 Physical Standards for Parcels

8.0 Additional Physical Standards by Class of Mail

9.0 Customized MarketMail

Machinable letter-size mail is:

- Not less than 5 inches long, 3-1/2 inches high, and 0.007-inch thick.

- 0.007 inch thick if no more than 4-1/4 inches high and 6 inches long; or

- 0.009 inch thick if more than 4-1/4 inches high or 6 inches long, or both.

- Not more than 11-1/2 inches long, or more than 6-1/8 inches high, or greater than 1/4-inch thick.

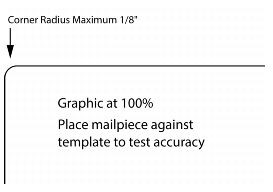

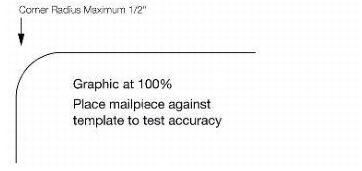

- Rectangular, with four square corners and parallel opposite sides. Letter-size, card-type mailpieces made of cardstock may have finished corners that do not exceed a radius of 0.125 inch (1/8 inch) unless prepared as Customized Market Mail under 243.9.0. See Exhibit 1.1.1.

- Within an aspect ratio (length divided by height) of 1.3 to 2.5, inclusive. See 3.7.

- Subject to additional dimensional restrictions in 3.0, depending on mailpiece design.

Exhibit 1.1.1 Maximum Corner Radius for Letter-Size, Card-Type and Flat-Size Mailpieces

The maximum weight for Presorted First-Class Mail machinable letters is 3.3 ounces (0.2063 pound). The maximum weight for Standard Mail machinable letters is 3.3 ounces (0.2063 pound).

All machinable letters must meet the additional standards for automation-compatible letters in 3.0.

Each card (each stamped card or postcard or each half of a double stamped card or postcard) claimed at a card price must be:

- Not less than 3-1/2 inches high, 5 inches long, and 0.007 inch thick.

- Not more than 4-1/4 inches high, or more than 6 inches long, or greater than 0.016 inch thick.

- Rectangular, with four square corners and parallel opposite sides. Card-size pieces meeting the standards in 1.2.1 may have finished corners that do not exceed a radius of 0.125 inch (1/8 inch). See

Exhibit 1.1.1.

A card that does not meet the applicable standards in 1.2 must not bear the words “Postcard” or “Double Postcard.”

A card must be of uniform thickness and made of unfolded and uncreased paper or cardstock of approximately the quality and weight of a stamped card (i.e., a card available from the USPS). A card must be formed either of one piece of paper or cardstock or of two pieces of paper permanently and uniformly bonded together. The stock used for a card may be of any color or surface that permits the legible printing of the address, postmark, and any required markings.

A card may bear an attachment that is:

- A paper label, such as a wafer seal or decal affixed with permanent adhesive to the back side of the card, or within the message area on the address side (see 1.2.6), or to the left of the address block.

- A label affixed with permanent adhesive for showing the delivery or return address.

- A small reusable seal or decal prepared with pressure-sensitive and nonremovable adhesive that is intended to be removed from the first half of a double card and applied to the reply half.

A card may not bear an attachment that is:

- Other than paper.

- Not totally adhered to the card surface.

- An encumbrance to postal processing.

The address side of a card is the side bearing the delivery address and postage. The address side may be formatted to contain a message area. Cards that do not contain a message area on the address side are subject to the applicable standards for the price claimed. For the purposes of 1.2, miscellaneous graphics or printing, such as symbols, logos, or characters, that appear on the address side of cards not containing a message area are generally acceptable provided the items are not intended to convey a message. Cards claimed at the Presorted or automation card prices that contain a message area on the address side must be divided vertically or horizontally and meet the following additional standards, as applicable:

- Vertically divided cards.

- The address side of the card must be divided into a right portion and a left portion, with or without a vertical rule. The left portion is the message area.

- The delivery address, postage, and any USPS marking or endorsement must appear in the right portion. The right portion must be at least 2-1/8 inches wide (measured from the right edge of the card, top to bottom inclusive).

- For cards claimed at the Presorted price, nondelivery address information may extend into the right portion only above the address block and if the information is shaded or surrounded by a border that has at least 1/8 inch clearance between the delivery address block and the border. Mailers may choose not to shade or border the nondelivery address information if there is at least 1/8 inch of clear space around the delivery address block.

- For cards claimed at the automation price, the standards for automation-compatible mail in 3.0, and 202.5.0, must be met.

- Horizontally divided cards.

- The address side of the card must be divided into an upper portion and a lower portion, with or without a horizontal rule. The portion of the address side that does not contain the delivery address is the message area.

- The delivery address, postage, and any USPS marking or endorsement must appear within the portion containing the delivery address. As an alternative, when the delivery address appears within the lower portion, it is permissible for the postage, return address, and any USPS marking or endorsement to appear in the upper portion. The portion bearing the delivery address must be at least 1-1/2 inches high (measured from the top or bottom edge of the card, as applicable, right edge to left edge inclusive).

- For cards claimed at the Presorted price, nondelivery address information may extend into the portion containing the delivery address only if it appears above the address block and if the information is shaded or surrounded by a border that has at least 1/8 inch clearance between the delivery address block and the border. Mailers may choose not to shade or border the nondelivery address information if there is at least 1/8 inch of clear space around the delivery address block.

- For cards claimed at the automation price, the standards for automation-compatible mail in 3.0, and 202.5.0, must be met.

A card may have perforations or tearing guides if they do not eliminate or interfere with any address element, postage, marking, or endorsement and do not impair the physical integrity of the card.

A double card (a double stamped card or double postcard) consists of two attached cards, one of which is designed to be detached by the recipient and returned by mail as a single card. Double cards are subject to these standards:

- The reply half of a double card must be used for reply only and may not be used to convey a message to the original addressee or to send statements of account. The reply half may be formatted for response purposes (e.g., contain blocks for completion by the addressee).

- A double card must be folded before mailing and prepared so that the address on the reply half is on the inside when the double card is originally mailed. The address side of the reply half may be prepared as business reply mail, courtesy reply mail, meter reply mail, or as a merchandise return service label.

- Plain stickers, seals, or a single wire stitch (staple) may be used to fasten the open edge at the top or bottom once the card is folded if affixed so that the inner surfaces of the cards can be readily examined. Fasteners must be affixed according to the applicable preparation requirements for the price claimed. Any sealing on the left and right sides of the cards, no matter the sealing process used, is not permitted.

- The first half of a double card must be detached when the reply half is mailed for return.

Enclosures in double postcards are prohibited at card prices.

A letter-size piece is nonmachinable if it has an exterior surface that is not made of paper or if it does not meet the standards in 3.0. A mailpiece is nonmailable if it does not meet the minimum dimensional standards in 1.1.1. Windows in envelopes made of paper do not make mailpieces nonmachinable. Attachments do not render mailpieces nonmachinable if allowed by eligibility standards according to the class of mail and if not prohibited in 3.0. In addition, a letter-size piece is nonmachinable if it weighs more than 3.3 ounces, unless it has a barcode, weighs no more than 3.5 ounces, and is eligible for and claims automation letter prices or Standard Mail Carrier Route (barcoded) letter prices.

Letter-size pieces (except cards) that meet one or more of the nonmachinable characteristics in 2.1 are subject to the nonmachinable prices (see 233.1.4). All letter-size pieces over 3.5 ounces are prepared as letters and charged the flat-size prices. An envelope weighing no more than one ounce with one enclosed standard optical disc no larger than 12 centimeters in diameter, that is mailed to or from a subscriber as part of a round-trip mailing under 233.2.8 and 505.1.0 (or 507.1.0), is not subject to the nonmachinable surcharge.

The nonmachinable prices in 243.1.0 apply to Standard Mail letter-size pieces that have one or more of the nonmachinable characteristics in 2.1. Mailers must prepare all nonmachinable letters as described in 245.5.0.

The nonbarcoded letter prices in 207 apply to Periodicals letter-size pieces that have one or more of the nonmachinable characteristics in 2.1.

[1-17-16] Mailers are encouraged, but not required, to design and produce Priority Mail Express and Priority Mail letter-size pieces as machinable letters.

Letters and cards claimed at any machinable, automation, or Standard Mail carrier route price, must meet the standards in 3.0. Unless prepared as a folded self-mailer, booklet, or postcard under 3.14 through 3.17, each machinable or automation letter must be a sealed envelope (the preferred method) or unenveloped. If unenveloped, each letter must be sealed or glued completely along all four sides or prepared under 3.15.

[6-6-16] Mailpieces should be constructed from high tear strength paper stock. All references in 3.0 to paper basis weight are for book-grade paper (500 25-inch by 38-inch sheets) unless otherwise stated. Except as required under 3.0, envelopes, or letter-size mailpieces sealed along all four sides, must be made of paper with a minimum 50 pounds paper basis weight or equivalent. The conversion table in Exhibit 3.2 provides a paper basis weight cross-reference.

Exhibit 3.2 Paper Basis Weight Conversion Table

Each machinable or automation letter-sized piece must meet the dimensional standards in 1.1.1. Machinable or automation letter-sized pieces may be subject to additional dimensional restrictions in 3.0, depending on mailpiece design.

A letter-size mailpiece containing one disc and meeting the general standards in 3.0 and the specific standards in 3.4.3 is considered automation-compatible. A mailpiece with one enclosed disc not meeting these standards must be tested and approved for automation-compatibility. For this purpose, mailers must submit 5 sample mailpieces and a written request to the local postmaster or business mail entry manager for submission to the Pricing and Classification Service Center (PCSC).

Position the disc symmetrically at the vertical centerline and as near to the top edge of the mailpiece as is practical. Secure the disc to prevent it from shifting more than 1/2 inch in any direction. The maximum disc size is:

- 120 mm (4.7 inches) in diameter.

- 2 mm (0.08 inch) in thickness.

[6-6-16] Each enveloped letter must meet the basic standards for machinable letters in 1.0 and have the following characteristics:

- Height, not more than 6 inches or less than 5.5 inches high.

- Length, not more than 9.75 inches or less than 7.25 inches long.

- Thickness, not more than 0.25 inch or less than 0.009 inch thick.

- Weight, not more than 3 ounces.

- A piece up to 8 inches long must be made of paper with a minimum 70-pound paper basis weight or equivalent.

- A piece over 8 inches long (up to 9.75 inches long) must be made of paper with a minimum 80-pound paper basis weight or equivalent.

- Discs in mailpieces made of the minimum basis weight paper must be inserted into a protective sleeve.

- Not be a window envelope, unless tested and approved under 3.4.1.

3.4.4 Dimensions and Shape Standards for Automation-Compatible Unenveloped Disc Carriers

[6-6-16] Each unenveloped disc carrier must meet the basic standards for machinable letters in 1.0 and have the following characteristics:

- Height, not more than 6 inches or less than 5.5 inches high.

- Length, not more than 9.75 inches or less than 7.25 inches long.

- Thickness, not more than 0.25 inch or less than 0.009 inch thick.

- Weight, not more than 3 ounces.

- Be prepared from paper stock meeting the industry standard with a minimum 75-pound paper basis weight or equivalent, with none less than 71.25 pounds. The stock must be free from groundwood unless coated with a substance adding to the stock‘s ability to resist an applied bending force.

- Any folds or perforations in the mailpiece must be parallel to the address.

- Must meet the tabbing requirements for pieces prepared with folds or perforations parallel to the address provided in 3.14.

Discs in letter-sized envelopes and unenveloped disc carriers may not be enclosed in: packaging such as plastic “clamshells,” “plastic” “jewel cases,” or inflexible cardboard sleeves.

[1-17-16] The following maximum weight limits apply:

- Booklets and unenveloped disc carriers - 3 ounces.

- Machinable enveloped letters and cards - 3.3 ounces.

- Automation enveloped letters and cards - 3.5 ounces (see 3.6 for pieces over 3 ounces.)

Heavy letter mail (letter-size pieces over 3 ounces) must be prepared in a sealed envelope, may not contain stiff enclosures, and must have an 11-digit delivery point POSTNET or an Intelligent Mail barcode with a routing code in the address block (see 202.5.0).

The aspect ratio (length of the mailpiece divided by height) must be between 1.3 and 2.5, inclusive. Length and height are defined in 601.1.1.2.

An automation-compatible mailpiece may not be polywrapped, polybagged, or shrinkwrapped; have clasps, strings, buttons, or similar closure devices; or have protrusions that might impede or damage the mail or mail processing equipment.

Staples or saddle stitching may be used only on booklet-type mailpieces to join the bound edge (spine). Inserted staples or stitching must parallel the bound edge, seat tightly and securely, and have no protrusions that might impede or damage the mail or mail processing equipment.

Rigid items (e.g., pens, pencils, keys, bottle caps) are prohibited within mailpieces. Reasonably flexible items (e.g., credit cards) are permitted. Subject to 3.12, odd-shaped items (e.g., coins and tokens) are permitted if firmly affixed to and wrapped within the contents of the mailpiece and envelope to streamline the shape of the mailpiece for automated processing.

[6-6-16] Tabs may be made of paper, translucent paper, vinyl or plastic. Cellophane tape may be used as a closure when the saw-toothed cut edge is placed parallel to the edge being sealed. Tabs must not contain perforations. For tab size and placement for folded self-mailers see 3.14; for booklets see 3.16. Tab placement is subject to 1/4 inch variance in either direction. The following standards also apply:

- Translucent paper tabs should be made of paper with a minimum of 40-pound paper basis weight.

- Opaque paper tabs should be made of paper with a minimum of 60-pound paper basis weight with a tear strength of at least 56 grams of force in the machine direction (MD) and 60 grams of force in the cross direction (CD).

- When a barcode clear zone is required under 202.5.1, tabs in the barcode clear zone must have a paper face meeting the standards for background reflectance and, if the barcode is not preprinted by the mailer, the standards for acceptance of water-based ink.

- Vinyl tabs and cellophane tape closures are not acceptable within the barcode clear zone.

- Tabs must be tight against the edge of the mailpiece. A maximum 1/16-inch overhang is recommended.

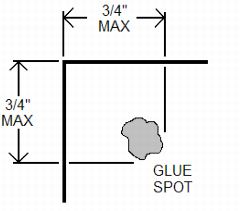

- Glue spots may be used in lieu of tabs (as indicated in Exhibit 3.16.5 through Exhibit 3.16.8) and must be placed within 3/4 inch of the open edges (see Exhibit 3.11f).

Exhibit 3.11f Glue Spot Placement

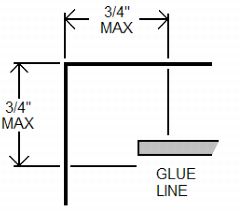

- Continuous glue lines may be used as cover-to-cover seals for specific designs. When using glue as a sealing method, it must be placed along the entire length of the open edge and end no more than 3/4-inch from the open ends (see Exhibit 3.11g) unless standards require use of a continuous 1/8-inch wide glue line under 3.11h. For folded self mailers see 3.13.4b.

Exhibit 3.11g Glue Line Placement

- Continuous, 1/8-inch wide, glue lines must be placed along the entire length of the open edge and end within 1/4-inch of the open ends. The selvage along the open edge must not exceed 1/4 inch. Glue lines created with a permanent adhesive that is not tacky when dry are preferred.

- Die-cut flaps, those with irregular shapes, must be well sealed to the non-address side panel using tabs, glue spots or elongated glue lines; however, a 1/8 inch continuous glue line that follows and seals the contour of the shape is highly recommended.

To ensure transport through automated mail processing machines, a mailpiece and its contents must bend easily when subjected to a transport belt tension of 40 pounds around an 11-inch-diameter drum.

A mailer requesting flexibility testing for letter-size mailpieces must submit at least 5 mailpieces and a written request to their local postmaster or business mail entry manager for submission to the Pricing and Classification Service Center (PCSC) at least 6 weeks before the mailing date. The request must describe mailpiece contents and construction, number of pieces being produced, and preparation level. The PCSC will evaluate the piece and, if warranted, will instruct the mailer to submit samples to USPS Engineering for testing. The PCSC advises the mailer of its findings. If the mailpiece is approved, the letter includes a unique number identifying the piece and serves as evidence that the piece meets the relevant standards. A copy of the letter must accompany each postage statement submitted for mailings of the approved piece. If requested by the USPS, the mailer must show that pieces presented for mailing are the same as those approved.

3.13.1 Use

A label, sticker, perforated pocket (under 3.13.6 and 3.13.7), or release card may be placed on a letter-sized mailpiece that is eligible for automation letter prices, including barcoded carrier route letters meeting automation standards. Release cards and perforated pockets may not be affixed to pieces mailed at First-Class Mail card prices; see 1.2 for other restrictions on attachments to cards. A Standard Mail or Periodicals letter with a label, sticker, release card or perforated pocket must meet additional standards in 243.2.5 These attachments may be:

- A label or sticker less than 0.007 inch thick, and a perforated pocket other than repositionable notes affixed under 202.7.0, as follows:

- A permanent label or sticker, or perforated pockets under 3.13.7d2 (designed not to be removed or relocated), affixed directly to the outside of the mailpiece with permanent adhesive.

- A relocatable label, to be placed on the outside of, or on the contents of, a reply mailpiece. Labels must be affixed under 3.13.2 or 3.13.3.

- Up to two release cards, each at least 0.007 inch and no more than 0.012 inch thick, secured to a letter with a liner or backing under 3.13.4.

- On pieces mailed at First-Class Mail, Periodicals, or Standard Mail prices, only if permitted by the applicable content and eligibility standards.

Any pressure-sensitive label or sticker affixed directly to a mailpiece before mailing must have a minimum peel adhesion to stainless steel of 8 ounces/inch. This standard does not apply to pressure-sensitive labels provided by the USPS to label bundles to sortation levels.

A face stock/liner label (“sandwich” label) is a two-part unit with a face stock (top label) attached to a liner (bottom label) affixed to the mailpiece. The face stock must have a peel adhesion value of at least 2 ounces/inch with respect to the liner label and at least 8 ounces/inch when reapplied to stainless steel.

[6-6-16] A letter-size mailpiece, with one or two attached release cards, must have the following characteristics:

- Be between 8 and 9-1/2 inches long (inclusive). With one release card affixed, be between 4 and 6 inches high (inclusive); with two release cards affixed, be between 5-1/2 and 6 inches high (inclusive).

- No address element, including any address block barcode, may be closer than 1 inch to the right edge of the mailpiece.

- The surface smoothness of all letter-size pieces must be at least 190 Sheffield Units.

- Enveloped letters must be made of paper with a minimum 60-pound paper basis weight or equivalent, and have a maximum thickness of 1/8 (0.125) inch. Window envelopes must have only one closed panel address window, no larger than 1-1/2 x 4-1/4 inches.

- Card-type letters, not mailed at card prices, have a maximum thickness of 0.025 inch as mailed.

- All letter-size pieces other than enveloped letters and card-type pieces (such as folded self-mailers and booklets) must have a maximum thickness of 0.10 inch as mailed. Mailpieces with two affixed release cards must meet the following additional conditions:

- Pieces requiring tabs must be sealed with 1-1/2 inch nonperforated tabs, unless larger tabs are required by standards for the specific mailpiece design.

- Booklets must have a minimum cover weight of 70-pound paper basis weight or equivalent.

- Folded self-mailers must have a minimum cover weight of 100-pound paper basis weight or equivalent.

- Content insert shift must be no more than 5/8 inch horizontally and no more than 1/4 inch vertically.

- Release cards must meet the standards in 3.13.5.

One or two release cards, each at least 0.007 inch thick and no more than 0.012 inch thick, attached to a letter-size mailpiece must:

- Be rectangular, but allowed with finished corners having a radius of at least 1/8 inch up to 1/2 inch.

- Be between 2 and 2-1/2 inches (inclusive) high, and between 3 and 3-1/2 inches (inclusive) long. Affix each card with either edge parallel to the length of the mailpiece. Affix two cards on the same side of the mailpiece under these conditions:

- Stack cards vertically, one above the other, on the same side (address side or nonaddress side), or

- Affix the cards side-by-side across the mailpiece length on the nonaddress side only.

- Be affixed no closer to the bottom edge of the mailpiece than 7/8 inch and no further away from the bottom edge than 1-1/2 inches, and must not interfere with readability of the address, barcode, or postage information. When affixing two cards, these additional conditions apply:

- When affixing cards one above the other on the address side, maintain a space of at least 1/2 inch from the leading edge, the trailing edge and the top edge.

- When affixing cards one above the other on the nonaddress side, the right edge of the cards must be placed between 5 and 6 inches from the leading edge of the mailpiece, but no closer than 1/2 inch from the trailing edge. Maintain a space of at least 1/2 inch from the top edge.

- When affixing cards side by side on the nonaddress side, the right edge of the leftmost card must be placed at least 5 inches from the leading edge of the mailpiece, and the rightmost card must be placed at least 1/2 inch from the trailing edge of the mailpiece. Maintain a space of at least 1/2 inch from the top edge.

- Be affixed by machine to ensure adequate adhesion. Manually affixed attachments are not allowed.

- Be affixed to a liner (backing) and meet the following adhesion standards:

- Adhesive used to affix the backing to the mailpiece must have a peel adhesion of at least 2 pounds/inch to stainless steel with a 20 minute dwell time, at 300"/minute at 90 degrees per ASTM test D3330F.

- Adhesive used to attach the release card to the backing must have a peel adhesion of at least 1.5 ounces/inch to stainless steel with a 30 minute conditioning time, at 300"/minute at 90 degrees per ASTM test D3330F.

[6-6-16] Perforated pockets are permanent attachments to letter-sized mailpieces that may be opened to reveal a small printed insert. Advertising may be printed on the components used to create a perforated pocket and on the printed insert within. Perforated pockets may not be used to conceal or contain matter bearing personal information except as provided in 243.2.2. Perforated pockets may be used on letter-size Standard Mail and Periodicals and are not considered sealed against Postal inspection. When affixed to Periodicals mail, advertising printed on the perforated pocket and any inserted matter is counted as part of the total advertising content of the host publication. Pockets may be used in lieu of labels to bear a permit imprint indicia showing that postage is paid if indicia information does not appear on the perforated panel or on the perforations used to create the perforated panel. A maximum of two perforated pockets are permitted on eligible letter-size mailpieces that have the following characteristics:

- Be between 8 inches and 9-1/2 inches long (inclusive).

- Be between 4 inches and 5-1/2 inches high (inclusive).

- Mailpieces must be prepared with a minimum paper basis weight or equivalent as follows:

- Envelopes - 60 pound

- Booklets - 70 pound

- Folded Self-Mailers - 100 pound

- Oversized card-type letters paid at letter prices must be at least .012 in thickness.

- Perforated pockets may be affixed to the nonaddressed side of envelopes with one closed panel address window. Perforated pockets must be placed one inch closer to the trailing edge than the window.

- If tabs are used to seal a folded self-mailer prepared with perforated pockets the folded self-mailer must be sealed with 1-1/2 inch nonperforated tabs placed 1" from the top on the leading and trailing edges.

Perforated pockets may be attached to a letter-size mailpiece when the following conditions are met:

- The perimeter of the pocket is affixed with permanent glue with a minimum adhesive strength of 2 lbs/inch to stainless steel with 20 minute dwell time at 300" minute at 90 degrees per ASTM Test D3330F.

- The attached material has a minimum tear strength of 100gf (MD) and (CD) per TAPPI T414.

- The cut/tie ratio for perforation is 1:1 with a minimum tie size of 1 mm. One double cut may be made at the lower trailing edge corner of the perforated panel of the pocket.

- The pocket is:

- Between 1-1/2 inches and 2-3/4 inches in both height and length.

- Has an affixed area no more than 0.012 inch thick and a perforated panel no more than 0.03 inch thick. Perforated pockets may not exceed the thickness of the host mailpiece. They may not cause the host to have an uneven surface and must not interfere with readability of the address, barcode, or postage information.

- The length of each pocket is parallel to the length of the host mailpiece.

- Attached to the address side of a mailpiece they are:

- At least 1 inch from the bottom and leading edge.

- At least 1/2 inch from the top and trailing edge.

- Pockets attached to the nonaddressed side of the mailpiece are:

- At least 1 inch from the bottom edge.

- At least 1/2 inch from the top.

- At least 5 inches from the left edge but no closer than 1/2 inch from the right edge.

- Two perforated pockets are affixed on the same side of the mailpiece under these conditions:

- Stack perforated pockets vertically, one above than the other. Do not affix the pockets side by side across the mailpiece length.

- A space up to 1/2 inch is allowed between pockets.

A folded self-mailer is formed of two or more panels that are created when one or more unbound sheets of paper are folded together and sealed to make a letter-size mailpiece. The number of panels is determined by the number of sheets in the mailpiece and the number of times the sheets are folded. (For double cards see 1.2.8.)

[6-6-16] Folded self-mailers have the following characteristics:

- Height: A minimum of 3-1/2 inches and a maximum of 6 inches.

- Length: A minimum of 5 inches and a maximum of 10-1/2 inches.

- Thickness: A minimum of 0.007 inch; (0.009 inch if the height exceeds 4-1/4 inches or if the length exceeds 6 inches); the maximum thickness is 1/4 inch.

- Maximum Weight: 3 ounces.

- Rectangular, with four square corners and parallel opposite sides.

- Aspect ratio: within 1.3 to 2.5 (see 3.7).

- Maximum number of panels: 12, except under 3.14.2h.

- Quarter-folded self-mailers made of a minimum 70-pound paper basis weight or equivalent may have as few as 4 panels. Quarter-folded self-mailers made of 55 pound or greater newsprint must have at least 8 panels and may contain up to 24 panels.

Panels are created when a sheet of paper is folded. Each two-sided section (front and back) created by the fold is considered one panel. When a folded self-mailer is made of multiple sheets, multiply the number of sheets by the number of panels created when folding a single sheet to determine the total number of panels. The following conditions apply:

- External panels created by folding must be equal or nearly equal in size.

- The final folded panel creates the back (non-address) side of the mailpiece. The open edge of the back panel must be at the top or within 1inch of the top or trailing edge of the mailpiece. For horizontal folded tri-fold or multi-fold pieces, the addressed panel may be the final folded panel if the leading edge is sealed according to 3.14.4a.

- The final folded edge must be the bottom of a folded self-mailer unless prepared as an oblong. The final folded edge of an oblong folded self-mailer must be the leading (right) edge.

- Internal shorter panels must be covered by a full-size panel, and count toward the maximum number of panels. Optionally, internal shorter panels may be secured but must have only one edge that is shorter and be no further than one inch away from the edge of the external panel.

- Folding methods and the subsequent number of panels created when folding a single sheet of paper are:

- Bi-fold: folded once forming two panels.

- Tri-fold: folded twice forming three panels.

- Oblong: paper folded once to form two rectangular panels with one elongated dimension and parallel opposite sides. The final folded edge is on the leading (shorter) edge.

- Quarter-fold: folded twice with each fold at a right angle (perpendicular) to the preceding fold. One sheet of paper quarter-folded creates four panels.

- Flaps are formed when the final exterior panel is folded over and affixed to the unaddressed side of the mailpiece. Flaps must meet the following conditions:

- The folded edge of a flap must be flush with the top edge of the mailpiece and end one inch or more above the bottom edge, except under 3.14.3f4. Flaps must be at least 1-1/2 inches when measured from the top of the mailpiece.

- Flaps must be secured by a sealing method in 3.14.4.

- Flaps with die-cut shapes must be firmly secured with tabs, glue line, glue spots or elongated glue lines. A 1/8 inch wide continuous glue line that seals the contour of the die-cut is strongly recommended.

- Flaps on oblong pieces must be at least 5 inches long at the longest point when measured from the leading edge and must end more than one inch from the trailing edge.

- Flaps and pockets prepared within folded self-mailers to stabilize enclosures are not considered to be panels.

Folded self-mailers must be sealed using tabs or glue under the following conditions (also see 3.14.5 for specific sealing standards):

- Tabs must meet the standards for tabs in 3.11. The size and number of tabs required is determined by the weight of the mailpiece and optional design elements as follows:

- To seal folded self-mailers that weigh up to 3 ounces created in bi-fold, tri-fold formats, pieces with multiple interior folds and a final fold on the bottom, and quarter-fold mailpieces that weigh up to one ounce; place two nonperforated tabs on the top edge, one within 1 inch from the leading edge and another within 1 inch from the trailing edge, or place one tab on the leading and another on the trailing edge, both placed within 1 inch from the top. Additionally, horizontal folded tri-fold and multi-fold pieces having the final folded panel as the addressed panel must include an additional 1-inch tab (1-1/2 inch preferred) for pieces weighing up to 1 ounce; or a 1-1/2 inch tab for pieces weighing over 1 ounce, placed 1/2 inch from the bottom of the leading edge. Instead of a tab, a 3/8-inch glue spot or 1/8-inch wide glue line placed 1/2 inch from the bottom and no more than 1/4 inch from the leading edge may be used. The glue spots or lines must be adhered from the addressed panel to the internal panel when the fold is completed.

- To seal quarter-fold mailpieces made with newsprint that weigh more than 1 ounce up to 3 ounces, affix two tabs, one on the leading edge and one on the trailing edge within 1 inch from the top, and affix a third tab on the lower leading edge 1/2 inch from the bottom (see 3.14.5b).

- To seal oblong pieces that weigh up to 3 ounces, affix one tab in the center of the top edge and one tab in the center of the trailing edge (preferred) or affix both tabs on the trailing edge within 1 inch of the top and bottom edges. Tabs may not be placed on the bottom of an oblong piece.

- Glue must be positioned within 1/4 inch of the open edges and be placed opposite the final fold or on both the leading and trailing edges when the final panel fold is on the bottom. Apply glue by one of the following methods:

- Continuous glue lines at least 1/8 inch wide (0.125 inches).

- Three or four glue spots at least 3/8 inch (0.375 inch) in diameter.

- Three or four elongated glue lines. Seal folded self-mailers that weigh up to 1 ounce with lines at least 1/2 inch long. Seal folded self-mailers that weigh more than 1 ounce with elongated glue lines that are each at least 1 inch long and 1/8 inch wide, or with glue lines that are each at least 1/2 inch long and 1/4 inch wide.

- Distribute glue spots and elongated glue lines evenly along the sealed edge(s).

- Quarter-fold self-mailers must be sealed with tabs.

[6-6-16] All references in 3.0 to paper basis weight are for book-grade paper unless otherwise stated (see 3.2). Interior optional elements such as attachments or enclosures are not subject to the host piece‘s book-grade paper basis weight standards. When multiple optional design elements are incorporated in one mailpiece, the standards for the design element with the highest paper weight and corresponding sealing methods apply. Folded self-mailer paper weights and sealing methods are:

- Folded self-mailers, (except quarter-fold mailpieces) as described in 3.14.3e1 through 3.14.3e3:

- Up to 1 ounce: 70-pound paper basis weight or equivalent sealed with a continuous glue line, three glue spots; or elongated glue lines under 3.14.4b; or two 1-inch tabs under 3.14.4a1 and 3.14.4a3.

- Over 1 ounce: 80-pound paper basis weight or equivalent sealed with a continuous glue line, four glue spots; or four elongated glue lines under 3.14.4b or two 1-1/2 inch tabs under 3.14.4a1 and 3.14.4a3.

- Quarter fold self-mailers as described in 3.14.3e4:

- Up to 1 ounce: 70-pound paper basis weight or equivalent sealed with two 1-inch tabs.

- Over 1 ounce: 80-pound paper basis weight or equivalent sealed with two 1-1/2-inch tabs.

- Newsprint: 55 pound minimum paper required. Seal pieces one ounce or less with two 1-1/2-inch tabs and those weighing over one ounce with three 1-1/2-inch tabs, see 3.14.4a2.

- Optional design elements: Die-cut openings and perforated panes. Folded self-mailers with die-cut openings in the exterior panels as described in 3.14.6 or perforated panes as described in 3.14.7 must meet the following:

- Up to 1 ounce: 100-pound paper basis weight or equivalent sealed with glue under 3.14.4b or two 1-1/2-inch tabs under 3.14.4a1 and 3.14.4a2.

- Over 1 ounce: 120-pound paper basis weight or equivalent sealed with glue under 3.14.4b or two 2-inch tabs under 3.14.4a1 and 3.14.4a2 or three 1-1/2-inch tabs under 3.14.4a3.

- Optional design elements: Loose enclosures or attachments. For folded self-mailers that have loose enclosures as described in 3.14.8 or attachments as described in 3.14.9, the following applies:

- Up to 1 ounce: 80-pound paper basis weight or equivalent sealed with glue under 3.14.4b or two 1- 1/2-inch tabs under 3.14.4a1 and 3.14.4a2.

- Over 1 ounce: 100-pound paper basis weight or equivalent sealed with glue under 3.14.4b or two 2-inch tabs under 3.14.4a1 and 3.14.4a2 or three 1-1/2-inch tabs under 3.14.4a3.

Folded self-mailers may be produced with two types of die-cut elements in the exterior panels: address windows or die-cut reveal. Die-cut openings may not be used to create die-cut punched holes (openings in the same location on all layers and panels so that there is a hole through the entire mailpiece). Prepare die-cut elements as follows:

- Die-cut address windows (used to convey address information) must meet standards for window envelopes under 601.6.3 and meet the following additional conditions:

- The maximum window size is 4 inches long by 2 inches high.

- When an address window appears on a mailpiece, no other die-cut openings may be made on the exterior panels.

- Die-cut openings used to reveal the contents of the mailpiece must be:

- Limited to two on only one external panel.

- Either circular with a 2-inch maximum diameter or rectangular with a maximum of 2 inches long by 1-1/2 inches high with slightly rounded 1/4 inch radius corners.

- Placed at least 1-1/2 inches from all edges of the mailpiece if on the addressed side.

- Placed at least 5 inches from the leading edge and 1-1/2 inches from all other edges if on the non-addressed side.

- Positioned at least 1-1/2 inches apart when two or more die-cut openings are used.

- A single 1/2-inch semi-circular die-cut thumb notch may be placed on the trailing edge of the addressed or unaddressed outer panel.

Folded self-mailers may be prepared with strips called panes that are pulled open to reveal the contents. These design elements must be placed only on the unaddressed side of the mailpiece and may be rectangular, circular, or oval shaped. Perforations, a row of small holes punched in a sheet of paper so that a section can be torn easily, are used to create pull-open strips, pop-out, or pop-open panes subject to the following requirements:

- Two parallel perforated lines must be spaced at least 1/2 inch apart creating a pull open strip. Position perforated strips parallel to the height of the mailpiece at least 5 inches from the leading edge and 2 inches from the trailing edge. Position perforated strips parallel to the length of the mailpiece at least 1 inch from the top. Perforations have a 1mm cut (max)/1mm tie (min) ratio.

- Pop-out panes with perforations around the outer edges have a maximum size of 4 inches long by 4 inches high. The following conditions apply:

- Place panes at least 1 inch from any edge.

- Use 1mm cut (max)/1mm tie (min) ratio.

- When using two panes, space them at least 1 inch apart.

- Address elements may not appear in perforated openings.

- Pop-open panes with perforations on three sides must meet the following conditions:

- The outer edges of the pull-open panel are a maximum of 4 inches long by 4 inches high.

- If prepared with multiple panes, they must be spaced at least 1 inch apart.

- Panes must be placed at least 1 inch from all edges.

- Perforation patterns have 1 mm cut (max)/1 mm tie (min) ratio.

- Perforated panes may not be prepared on pieces with die-cuts or on any mailpiece made of newsprint.

Folded self-mailers with loose enclosures must be securely sealed to ensure containment of the enclosed material and prevent excessive enclosure shift during processing. Loose enclosures must be made of paper and must meet the following conditions:

- Must be contained securely within the mailpiece.

- Must be inserted in an interior pocket or secured by any method that prevents excessive shift during normal handling. Pockets are not counted as panels.

- Folded self-mailers with die-cut openings may contain enclosures only if the inserted material is larger than the die-cut opening.

- Enclosed material does not exceed the maximum thickness of:

- 0.05 inch thick for mailpiece weights up to 1 ounce.

- 0.09 inch thick for mailpiece weights over 1 ounce.

- One empty reply envelope may be inserted within the first fold (manufacturing fold) of a quarter-folded self-mailer and must be secured within a fold to prevent separation during normal handing.

Attachments must be secured on the outside of a folded self-mailer under 3.13. Attachments must be secured within a folded self-mailer under the following conditions:

- The attachment is affixed to an inside panel and secured to it at least 1/2 inch from any edge.

- The attached material may not exceed a maximum thickness of:

- 0.05 inch thick for mailpieces weighing up to 1 ounce.

- 0.09 inch thick for mailpieces weighing over 1 ounce.

- Multiple attachments must be positioned so that the host mailpiece remains nearly uniform in thickness.

- When multiple attachments are affixed to separate panels in stacked alignment, the combined thickness of the attachments must be no greater than the maximum thickness in 3.14.9b.

- When multiple attachments are affixed adjacent to each other across the length of a mailpiece, the thickest attachment must be no greater than the maximum thickness in 3.14.9b.

- Folded self-mailers with die-cut openings may contain attachments if the inserted material is larger than the die-cut opening.

- Quarter-fold self-mailers may have only one internal attachment not exceeding 0.012 inch thick. The attachment must be secured at least 1/2 inch from all edges.

When folded self-mailers are prepared with uncoated paper, printing addresses in a center or left-justified position within the optical character reader (OCR) area under 2.1 is recommended.

Open-sleeve style letter-size mailpieces consists of two symmetrical horizontal panels sealed together along the top and bottom edges or as a bi-fold that has a non-addressed panel permanently sealed to an inner flap along the top edge. Open-sleeve style mailpieces must meet the following conditions:

- Join panels using 1/8 (0.125) inch continuous glue lines.

- If flaps are used, they must be a minimum of at least 1-1/2 inches wide created as inner flaps adhered at the leading and trailing edges to the panel from which the flap is formed.

- All paper basis weight requirements in 3.14.5d must be met.

- Matter prepared within open-sleeve style mailpieces must meet the standards in 3.14.8 or 3.14.9b through 3.14.9f.

[6-6-16] When letter-size mailpieces have tear-off strips on the leading and/or trailing edge, any unfolded edges must be sealed with an adhesive (glue) or by a cohesive (pressure seal) method. A cohesive seal requires two fixative patterns placed on two separate surfaces that are compressed to form a bond. A perforated horizontal line that runs between and joins the leading and trailing edge perforation lines is permitted. Mailpieces with sealed sides must meet the following conditions.

- Be constructed of a minimum of 60-pound paper basis weight or equivalent.

- Tear-off strips may be up to 9/16 inch (0.5625) wide.

- Tear lines (single lines of perforations) on pieces that weigh 1 ounce or less; recommended minimum cut/tie pattern of 1mm cut (max)/1mm tie (min) ratio or equivalent.

- Tear lines (single lines of perforations) on pieces that weigh more than 1 ounce; minimum cut/tie pattern of 1mm cut /2mm tie (min) ratio or equivalent.

Booklets must have a bound edge (spine.) Sheets that are fastened with at least two staples in the manufacturing fold (saddle stitched), perfect bound, pressed-glued, or joined together by another binding method that produces a spine where pages are attached together are considered booklets. Booklets are open on three sides before sealing, similar in design to a book. In general, booklets must be uniformly thick. Large bound booklets that are folded for mailing may qualify for automation and machinable prices if the final mailpiece remains nearly uniform in thickness and conforms to all other automation standards.

Booklet covers generally must be made with a minimum paper basis weight of 60-pounds or equivalent. Minimum basis weights are higher for some designs (see 3.16.4).

Booklets must be:

- Height: not more than 6 inches or less than 3.5 inches high.

- Length: not more than 10.5 inches or less than 5 inches long. See Exhibit 3.16.5 through Exhibit 3.16.8 for some booklet designs with shorter maximum lengths.

- Thickness: not more than 0.25 inch or less than 0.009 inch thick.

- Weight: not more than 3 ounces.

- Aspect ratio: within 1.3 to 2.5 (see 3.7).

The position of the final fold and intermediate fold (or spine) for letter-sized booklets varies according to the specific design of the mailpiece. Open edges can be sealed with tabs, cellophane tape, glue lines, or glue spots. Except for the simple spine wallet-style design with a height of 4 inches and a maximum length of 8 inches; tabs used as seals on the leading edge of small booklets less than 5 inches high, may be placed closer to the top and bottom edges than shown in Exhibit 3.16.5 through Exhibit 3.16.8 and may overlap in some cases. See Exhibit 3.16.5 through Exhibit 3.16.8 for design and sealing standards by type of design.

[6-6-16] The spine forms the bottom edge of the mailpiece. The length or method used to seal the booklet determines the weight of the paper forming the cover.

Exhibit 3.16.5 Simple Spine Booklets

[6-6-16] A spine forms the bottom edge. Wallet style booklets must be from 5.2 inches to 8 inches long, 4 inches high; can weigh up to 2.5 ounces; and must be sealed with nonperforated tabs. Tab size and placement are dictated by the weight of the booklet.

Exhibit 3.16.6 Wallet Style Booklets

Exhibit 3.16.6

[6-6-16] Oblong booklets have a spine on the leading (shorter) edge.

Exhibit 3.16.7 Oblong Booklets

Exhibit 3.16.7

[6-6-16] Folded booklets are mailpieces that are bound and then folded to letter-size. The folded spine may be the leading edge or at the top of the booklet. If necessary, the booklet may be prepared with the spine as the trailing edge, however, this configuration is not recommended. The cover is at least 40-pound paper. Folded booklets must be sealed with nonperforated 1.5" tabs.

Exhibit 3.16.8 Folded Booklets

Exhibit 3.16.8

[6-6-16] Any postcard must be prepared from paper stock meeting the industry standard with a minimum 75-pound paper basis weight or equivalent, with none less than 71.25 pounds (measured weight for 500 25- by 38-inch sheets). The stock must be free from groundwood unless coated with a substance adding to the stock’s ability to resist an applied bending force. A double postcard not prepared with all edges sealed must have the folded edge at the top or bottom, and the open edge parallel to the address must be secured with one tab (or other permitted closure) in the middle of the length. Pieces claimed at First-Class Mail automation card prices also must meet the standards in 1.2.

Mailers may enclose reply cards or envelopes, addressed for return to a domestic delivery address, within automation mailings subject to provisions in 3.0 for enclosures. For Business Reply Mail (BRM) see 505.1.0, for pre-paid reply mail (also known as Metered Reply Mail) or Courtesy Reply Mail (CRM) see 505.2.5.

Flat-size mail must have the following characteristics:

- Be more than 11-1/2 inches long, or more than 6-1/8 inches high, or more than 1/4 inch thick, other than automation flats under 6.0 or as allowed for Standard Mail pieces with simplified addresses under 5.2.2. Mailpieces other than automation flats or Standard Mail pieces with simplified addresses that are 1/4 inch thick or less must be at least 3-1/2 inches high and at least 5 inches long and be at least 0.007 inch thick.

- Be not more than 15 inches long or more than 12 inches high or more than 3/4 inch thick, except for:

- Periodicals flats mailed under 207.26.0.

- Polywrapped flats, with selvage that extends beyond the contents, up to a maximum length of 15-3/4 inches. The enclosed contents must not be longer than 15 inches. Also see 4.5.3.

- Be rectangular with four square corners or with finished corners that do not exceed a radius of 0.125 inch (1/8 inch) unless prepared as Customized Market Mail under 705.1.0. See Exhibit 1.1.1.

- Be categorized as a catalog, if meeting the standards in 4.9.

- Other size or weight standards may apply to mail addressed to certain APOs and FPOs, and mail sent by the Department of State to U.S. government personnel abroad.

The length of a flat-size mailpiece is the longest dimension. The height is the dimension perpendicular to the length. When determining the maximum height or length of a flat, include any selvage of polywrap material that may enclose the piece. When determining the minimum height or length of a flat, do not include the selvage of any polywrap material that may enclose the piece. Also see 4.5.3.

Flat-size pieces must be flexible. Boxes—with or without hinges, gaps, or breaks that allow the piece to bend—are not flats. Tight envelopes or wrappers that contain one or more boxes are not flats. At the customer‘s option, customers may perform the following test on their own mailpieces. When a postal employee observes a customer demonstrating that a flat-size piece is flexible according to these standards, the employee should not perform the test. Test flats as follows:

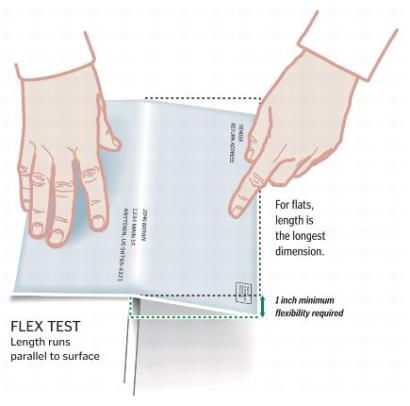

- All flats (see Exhibit 4.3a):

- Place the piece with the length parallel to the edge of a flat surface and extend the piece halfway off the surface.

- Press down on the piece at a point 1 inch from the outer edge, in the center of the piece‘s length, exerting steady pressure.

- The piece is not flexible if it cannot bend at least 1 inch vertically without being damaged.

- The piece is flexible if it can bend at least 1 inch vertically without being damaged and it does not contain a rigid insert. No further testing is necessary.

- Test the piece according to 4.3b or 4.3c below if it can bend at least 1 inch vertically without being damaged and it contains a rigid insert.

Exhibit 4.3a Flexibility Test—All Flats

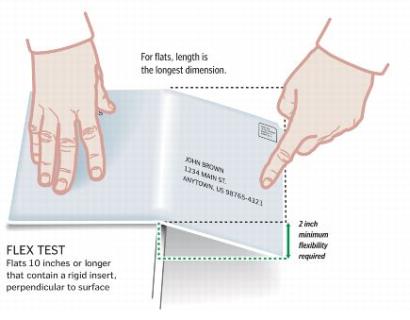

- Flats 10 inches or longer that pass the test in 4.3a and contain a rigid insert (see Exhibit 4.3b):

- Place the piece with the length perpendicular to the edge of a flat surface and extend the piece 5 inches off the surface.

- Press down on the piece at a point 1 inch from the outer edge, in the center of the piece‘s width, exerting steady pressure.

- Turn the piece around and repeat steps 1 and 2. The piece is flexible if both ends can bend at least 2 inches vertically without being damaged.

Exhibit 4.3b Flexibility Test—Flats 10 Inches or Longer

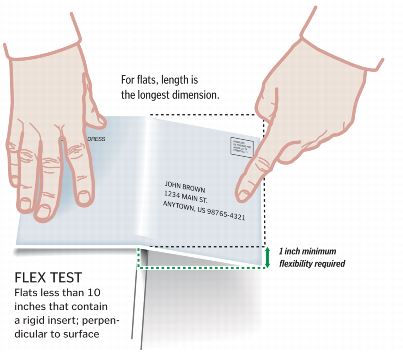

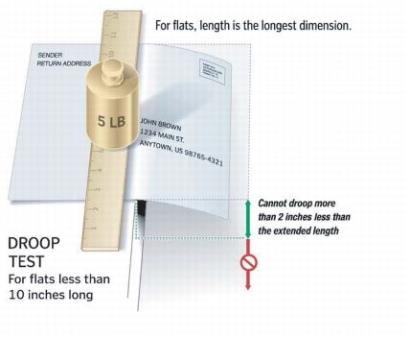

- Flats less than 10 inches long that pass the test in 4.3a and contain a rigid insert (see Exhibit 4.3c):

- Place the piece with the length perpendicular to the edge of a flat surface and extend the piece one-half of its length off the surface.

- Press down on the piece at a point 1 inch from the outer edge, in the center of the piece‘s width, exerting steady pressure.

- Turn the piece around and repeat steps 1 and 2. The piece is flexible if both ends can bend at least 1 inch vertically without being damaged.

Exhibit 4.3c Flexibility Test—Flats Less Than 10 Inches Long

Flat-size mailpieces must be uniformly thick so that any bumps, protrusions, or other irregularities do not cause more than 1/4-inch variance in thickness. When determining thickness, exclude the outside edges (1 inch from each edge) when the contents do not extend into those edges. Also, exclude the selvage of any polywrap covering (see 4.5) from this determination. Mailers must secure nonpaper contents to prevent shifting of more than 2 inches within the mailpiece if shifting would cause the piece to be nonuniformly thick or result in the contents bursting out of the mailpiece. (see 601.3.3).

Mailers using polywrap film or similar material on flat-size mailpieces (except pieces mailed at high density, high density plus, or saturation prices) must use a product meeting the standards in 4.5. Film approved for use under 4.5.4 must meet the specifications in Exhibit 4.5.1 as follows:

- If the address label is affixed to the outside of the polywrap, the haze property (property 2) does not apply.

- Only products listed as approved on the USPS RIBBS Web site (http://ribbs.usps.gov) may be used on flat-size mailpieces.

Exhibit 4.5.1 Polywrap Specifications

Mailers who polywrap flats, except for saturation and high density pieces, must use polywrap that meets all of the properties in this exhibit, except under 4.5.1b.

Exhibit 4.5.1

Wrap direction, seam direction, and seam placement must follow these standards:

- The wrap direction must be around the longer axis (parallel to the length) of the mailpiece, with the seam parallel to that axis.

- The polywrap over the address area must be a smooth surface to avoid interference with address and barcode readability. The preferred seam placement is on the nonaddressed side of the mailpiece. If the seam is placed on the addressed side, the seam must not cover any part of the address and barcode, postage area, or any required markings or endorsements.

For purposes of the polywrap standards for overhang (selvage) only, the top edge of the mailpiece is one of the two longer edges of the piece. Any polywrap selvage must meet these standards:

- When the mailpiece contents are totally positioned at the bottom of the polywrap, the overhang must not be more than 0.5 inch at the top of the mailpiece.

- When the mailpiece contents are totally positioned to the left or to the right side of the polywrap, the overhang must not be more than 1.5 inches on the opposite side.

- The polywrap covering must not be so tight that it bends the mailpiece.

Specification USPS-T-3204, Test Procedures for Polywrap Films describes exact test procedures and acceptable values for polywrap film characteristics. Independent testing laboratories may certify products for manufacturers who do not have the facilities or experience to conduct each of the test procedures. The specification includes a list of laboratories experienced in conducting these tests. Customers may obtain the test procedures by contacting USPS Engineering (see 608.8.1 for address) or on the USPS RIBBS Web site (http://ribbs.usps.gov). Manufacturers must submit a letter, on their letterhead, indicating the value for each of the specifications in 4.5.1 for each polywrap film, to USPS Product Classification (see 608.8.1 for address). When the USPS receives the letter or certificate of conformance from an approved lab, films that meet the standards will be listed on http://ribbs.usps.gov. Manufacturers should follow this process before submitting the certification letter:

- Test each film according to procedures listed in USPS-T-3204, Test Procedures for Polywrap Films.

- Test each surface treatment separately. Manufacturers or approved labs may test the thinnest film of one product with identical surface treatment and characteristics. If the thinnest film meets the characteristics after being tested, the USPS will list the product as approved for all gauges of that product that also meet the gauge test.

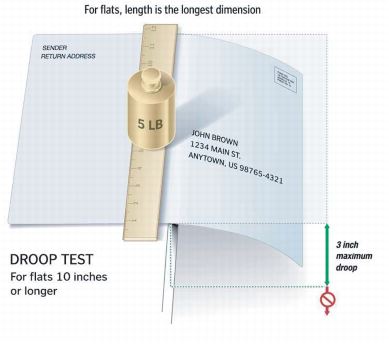

[10-3-16] [1-17-16] Flat-size mailpieces must meet maximum deflection standards. Flat-size pieces mailed at high density, high density plus, saturation, and basic carrier route prices are not required to meet these deflection standards. Test deflection as follows:

- For pieces 10 inches or longer (see Exhibit 4.6a):

- Place the piece on a flat, straight-edge surface with the length perpendicular to the edge of the surface and extend the piece 5 inches off the edge of the surface. Test square-shaped bound flats by placing the bound edge parallel to the edge.

- Place a flat 12-inch ruler (or other similar flat object 12 inches or longer) on top of the mailpiece with the length of the ruler parallel to the edge of the surface and as close to the edge as possible so that the 5-pound weight (see 4.6a) does not extend past the edge.

- Place a certified 5-pound weight on the center of the ruler to hold the piece in place.

- Determine the vertical deflection in inches.

- Turn the piece around 180 degrees and repeat the process.

- The piece is mailable as a flat if it does not droop more than 3 inches vertically at either end.

Exhibit 4.6a Deflection Test—Pieces 10 Inches or Longer

- For pieces less than 10 inches long (see Exhibit 4.6b):

- Place the piece on a flat, straight-edge surface with the length perpendicular to the edge of the surface and extend the piece one-half of its length off the edge of the surface. Test square-shaped bound flats by placing the bound edge parallel to the edge.

- Place a flat 12-inch ruler (or other similar flat object 12 inches or longer) on top of the mailpiece with the length of the ruler parallel to the edge of the surface and as close to the edge as possible so that the 5-pound weight (see 4.6b) does not extend past the edge.

- Place a certified 5-pound weight on the center of the ruler to hold the piece in place.

- Determine the vertical deflection in inches.

- Turn the piece around 180 degrees and repeat the process.

- The piece is mailable as a flat if it does not droop more than 2 inches less than the extended length at either end. For example, a piece 8 inches long would be extended 4 inches horizontally off a flat surface. It must not droop more than 2 inches vertically at either end.

Exhibit 4.6b Deflection Test—For Pieces Less Than 10 Inches Long

[1-17-16] Flat-size mailpieces that do not meet the standards in 4.3 through 4.6 must pay applicable higher prices as follows:

- Flat-size pieces that do not meet flexibility, uniform thickness, or polywrap standards in 4.3 through 4.5 must pay these applicable prices:

- First-Class Mail—parcel prices.

- Periodicals—parcel prices.

- Standard Mail—parcel prices.

- Bound Printed Matter—parcel prices.

- Flats that do not meet deflection standards in 4.6 must pay the applicable prices as noted in Exhibit 4.7b. Under the column heading “eligibility as presented,” flats will be considered to be presented as automation flats only if they meet all other eligibility standards for automation flats.

Exhibit 4.7b Pricing for Flats Exceeding Maximum Deflection

(see 4.6)

A label, sticker, or release card may be placed on a flat-sized mailpiece. Standard Mail flats with a label, a sticker, or a release card must meet additional standards in 243.2.5. These attachments may be:

- A label or sticker less than 0.007 inch thick, other than repositionable notes affixed under 705.22.0, as follows:

- A permanent label or sticker (designed not to be removed or relocated) affixed directly to the outside of the mailpiece with permanent adhesive.

- A relocatable label, to be placed on the outside of, or on the contents of, a reply mailpiece. Labels must be affixed under 4.8.2 or 4.8.3.

- Up to two release cards, each at least 0.007 inch thick and no more than 0.012 inch thick, when affixed according to 4.8.4 and 4.8.5.

- On pieces mailed at First-Class Mail, Periodicals, Standard Mail, or Package Services prices, only if permitted by the applicable content and eligibility standards.

Any pressure-sensitive label or sticker affixed directly to a mailpiece before mailing must have a minimum peel adhesion to stainless steel of 8 ounces/inch. This standard does not apply to pressure-sensitive labels provided by the USPS to mailers to label bundles for sortation levels.

A face stock/liner label (“sandwich” label) is a two-part unit with a face stock (top label) attached to a liner (bottom label) affixed to the mailpiece. The face stock must have a peel adhesion value of at least 2 ounces/inch with respect to the liner label and at least 8 ounces/inch when reapplied to stainless steel.

Mailings of flat-size mailpieces with a release card attached to the outside of each piece must include 8 pieces, as part of the mailing, addressed to “USPS Engineering—Flat Mail Technology” with the attention line: “Release Card Sample”, using the street address in 608.8.1. Flat-size mailpieces, with up to two attached release cards, must be between 6 and 12 inches (inclusive) high, between 8 and 15 inches (inclusive) long, between 0.02 and 0.75 inch (inclusive) thick as mailed, and meet the following conditions:

- All flats must be at least 6 inches high, at least 8 inches long, and at least 0.02 inch thick. In addition, nonautomation and carrier route flats must have at least one dimension larger than one maximum letter-size dimension. A flat with two attached release cards must have a minimum cover thickness of 0.003 inch.

- Enveloped flats must be made of paper with a minimum 60-pound book grade paper.

- Window envelopes must have only one closed panel address window.

- Bound flats must have a cover with a minimum thickness of 0.003 inches.

- Release cards must meet the standards in 4.8.5.

One or two release cards, each at least 0.007 inch thick and no more than 0.012 inch thick, may be attached to the same side of a flat-size mailpiece, and also must:

- Be rectangular, but allowed with finished corners having a radius of at least 1/8 inch up to 1/2 inch.

- Be between 2 and 2-1/2 inches high, and between 3 and 3-1/2 inches long. A card may be affixed with either edge parallel to the length of the mailpiece.

- Be affixed by machine to ensure adequate adhesion. Manually affixed attachments are not allowed.

- Be affixed, on the address side of the mailpiece, a minimum of 4 inches from the bottom of an enveloped or card-type mailpiece or from the binding of a bound flat and must not interfere with the readability of the address, barcode, or postage information. Maintain a clear space of at least 1/4 inch from all other edges when a release card is on the address side. Maintain a clear space of at least 1/4 inch from all edges when a release card is on the nonaddress side of a mailpiece.

- Be affixed to a liner (backing) and meet the following adhesion standards:

- Adhesive used to affix the backing to the mailpiece must have a peel adhesion of at least 2 pounds/inch to stainless steel with a 20 minute dwell time at 300"/minute at 90 degrees per ASTM test D3330F.

- Adhesive used to attach the release card to the backing must have a peel adhesion of at least 1.5 ounces/inch to stainless steel with a 30 minute conditioning time, at 300"/minute at 90 degrees per ASTM test D3330F.

A catalog is a bound flat-sized mailpiece with at least 16 pages, meeting the criteria in 4.0. Catalogs provide a listing of products offered for sale arranged systematically and includes images, photographs or illustrations of the products, descriptive details, and prices. Catalogs must contain an order form, a phone number, or a web address to place orders and provides shipping options for the products offered for sale.

These additional standards apply to First-Class Mail flat-size pieces:

- First-Class Mail flats cannot exceed 13 ounces. First-Class Mail flats weighing more than 13 ounces are Priority Mail.

- Flat-size pieces that do not meet the standards in 4.1 through 4.4 must be prepared as parcels and pay the applicable parcel price.

These additional standards apply to Standard Mail flat-size pieces:

- Each piece must weigh less than 16 ounces.

- Flat-size pieces that do not meet the standards in 4.3 through 4.5 must be prepared as parcels and pay the parcel prices.

Standard Mail flats with simplified addresses for which saturation flats prices are paid must have at least one dimension that is greater than a letter-size maximum dimension as noted in 4.1a. The minimum thickness must be at least 0.007 inch up to a maximum of 0.75 inch. As an exception to the minimum length, flats with simplified addresses may have a length shorter than a letter-size maximum length, under all of the following conditions:

- The length must be greater than 10.5 inches up to a maximum 15 inches.

- The height must be at least 3.5 inches up to a maximum height of 12 inches, but the height must be no greater than the length.

- If the piece is also entirely within letter-size dimensions under 201; the piece must bear an “EDDM” marking directly after the “ECRWSS” marking required in 202.3.5c..

- When the piece is mailed as part of a saturation flats mailing under applicable conditions in 602.3.2.

- Letter-size pieces that meet the size standards in 5.2.2a and 5.2.2b and that are addressed to rural routes may be mailed as letters or flats with simplified addresses at the mailer‘s option.

If the piece is not completely enclosed in a mailing wrapper, then any protective cover or cover page must cover both the front and back of the host publication and extend to within at least 3/4 inch of the edge opposite the fold or binding. Exception: Flat-size pieces may have short covers as provided in 6.4.2.

These additional standards apply to Bound Printed Matter:

- Flat-size pieces that do not meet the standards in 4.3 through 4.4 must be prepared as parcels and pay the applicable parcel prices.

- Bound Printed Matter may not weigh more than 15 pounds.

- Two or more flats may be mailed as a single piece if they are about the same size or shape or if they are parts of one article, if they are securely wrapped or fastened together, and if they do not together exceed the weight or size limits.

These additional standards apply to Media Mail and Library Mail:

- Flat-size pieces that do not meet the standards in 4.3 through 4.4 must be prepared as parcels.

- No piece may weigh more than 70 pounds.

- Two or more flats may be mailed as a single piece if they are about the same size or shape or if they are parts of one article, if they are securely wrapped or fastened together, and if they do not together exceed the weight or size limits.

[1-17-16] Mailers are encouraged, but not required to design and produce Priority Mail Express and Priority Mail flat-size pieces under the general standards in 4.0 and the automation standards in 6.0.

Flat-size pieces claimed at automation prices must meet the standards in 4.0 and in 6.0, and the eligibility standards for the class of mail and price claimed. For automation flats, the size standards in 6.2 supersede the size standards in 4.1.

Each flat-size piece must be rectangular, except that flat-size mailpieces may have finished corners that do not exceed a radius of 0.125 inch (1/8 inch). See Exhibit 1.1.1. The following minimum and maximum dimensions apply to First-Class Mail, Standard Mail, Periodicals (except under 207.26.0), and Bound Printed Matter pieces:

- Minimum height is 5 inches. Maximum height is 12 inches.

- Minimum length is 6 inches. Maximum length is 15 inches, except for polywrapped flats as allowed in 4.1.

- For bound or folded pieces, the edge perpendicular to the bound or folded edge may not exceed 12 inches.

- Minimum thickness is 0.009 inch. Maximum thickness is 0.75 inch.

[1-17-16] Maximum weight limits are as follows:

- For First-Class Mail, 13 ounces.

- For Periodicals, 20 ounces.

- For Standard Mail, less than 16 ounces.

- For Bound Printed Matter, 20 ounces.

Clasps, strings, buttons, or like materials, or other protrusions that impede or damage mail processing equipment are prohibited.

Staples must not be substituted for tabs or wafer seals on pieces in automation price mailings. As a binding method, staples may be placed in the fold or spine of a magazine or booklet-type or similar mailpiece if parallel with the bound edge, tightly and securely inserted, and not protruding to damage or interfere with mail processing equipment.

Although not required, mailpieces may be prepared with tabs, wafer seals, cellophane tape, or permanent glue (continuous or spot) if these sealing devices do not interfere with the recognition of the barcode, price marking, postage information, and delivery and return addresses. Cellophane tape may not be placed over the barcode or where any part of the barcode will be printed. Tabs or seals placed in the area on which any part of the barcode is printed must contain a paper face meeting the standards for background reflectance. Tabs, wafer seals, and tape must have a peel adhesion (shear strength) value of at least 15 ounces/inch at a speed of 12 inches/minute after application to a stainless steel plate; the test is to be conducted 10 minutes after the material is applied to the plate.

Flats may be prepared with a cover page or protective cover that is more than 3/4 inch from each edge if the cover page is secured with at least two tabs, wafer seals, or glue spots placed within 1 inch of the top and bottom edges of the cover page or protective cover.

A flat-size mailpiece prepared and claimed at automation prices must be uniformly thick (see 4.4). Each flat-size mailpiece must have a smooth and regular shape and be free of creases, folds, tears, or other irregularities not compatible with automation equipment. The exterior surface must not have protuberances caused by prohibited closures; attachments (except as provided below); irregularly shaped or distributed contents; or untrimmed excess material from the envelope, wrapper, or sleeve.

Except as allowed under 4.8, an attachment to a flat-size mailpiece must be a single sheet, the same size as the cover. The attachment must be permanently, securely, and uniformly affixed to the front or back cover along a bound, folded, or otherwise closed edge, except as allowed under 4.8. Pieces claimed at a Periodicals price may bear attachments only if permitted by the applicable standards.

The contents of flat-size mailpieces prepared in sleeves or other wrappers must be sufficiently secure in the sleeve or wrapper to stay in place during processing. If material bearing the delivery address or barcode for the mailpiece is enclosed in a partial wrapper, that wrapper must be sufficiently secure to prevent the contents from shifting and obscuring the delivery address or barcode.

[1-17-16] USPS categorizes parcels into one of three mail processing categories: machinable, irregular, or nonmachinable. These categories are based on the physical dimensions of the piece, regardless of the placement (orientation) of the delivery address on the piece.

Pieces are subject to the minimum standards in 7.5, and may be subject to other minimum dimensions, based on the standards for specific prices. All parcels must be large enough to hold the required delivery address, return address, mailing labels, postage, barcode, endorsements, and other mail markings on the address side of the parcel. For mailability, all pieces 1/4 inch thick or less must be a minimum of 5 inches in length, 3-1/2 inches in height, and 0.007 inch in thickness.

No mailpiece may weigh more than 70 pounds. Lower weight limits apply to parcels mailed at Priority Mail Commercial Plus Cubic, Regional Rate Box, First-Class Package Service, Standard Mail, and Bound Printed Matter prices. Pieces may not measure more than 108 inches in length and girth combined, except Parcel Select. Standard Mail Marketing parcels (see 8.4) may not be larger than 12 inches long, 9 inches high, and 2 inches thick. Parcel Select parcels may not measure more than 130 inches in length and girth combined. For parcels, length is the distance of the longest dimension and girth is the distance around the thickest part. Lower size or weight standards apply to mail addressed to some APOs and FPOs subject to 703.2.0 and 703.4.0 and for Department of State mail, subject to 703.3.0.

With the exception of USPS-produced Flat Rate Envelopes and Boxes, two or more packages may be mailed as a single parcel if they are about the same size or shape, are securely wrapped or fastened together, and do not exceed the weight or size limits.

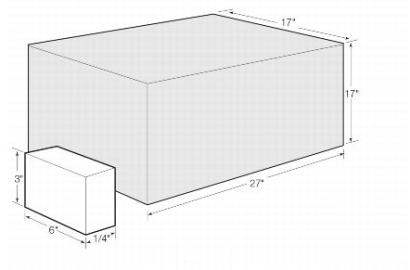

A machinable parcel is any piece that is not a letter or a flat and that is (see Exhibit 7.5.1b):

- Not less than 6 inches long, 3 inches high, 1/4 inch thick, and 6 ounces in weight, except under 7.5.2. A mailpiece exactly 1/4 inch thick is subject to the 3 1/2-inch height minimum.

- Not more than 27 inches long, or 17 inches high, or 17 inches thick. Parcels cannot weigh more than 25 pounds, except Parcel Select and Parcel Return parcels which have a maximum weight of 35 pounds, except for those containing books or other printed matter (25 pound maximum).

Exhibit 7.5.1b Machinable Parcel Dimensions

- Except for machinable parcels described in 7.5.2, pieces mailed at parcel prices may have finished corners that do not exceed a radius of 0.5 inch (1/2 inch). See Exhibit 7.5.1c.

Exhibit 7.5.1c Maximum Corner Radius for Parcels

A parcel that weighs less than 6 ounces (but not less than 3.5 ounces) is machinable if it meets all of the following conditions:

- The mailpiece is rectangular and able to maintain its integrity during mail processing (see 601.4.0).

- Mailpieces weighing at least 3.5 ounces but less than 5 ounces must be a paperboard or fiberboard box within the following dimensions:

- At least 1.5 inches thick and no more than 3 inches thick.

- At least 6 inches long and no more than 7 inches long.

- At least 3.5 inches high and no more than 5 inches high.

- Mailpieces weighing at least 5 ounces but less than 6 ounces must be within the following dimensions:

- More than 3/4 inch thick and no more than 6 inches thick.

- At least 6 inches long and no more than 12 inches long.

- At least 3-1/2 inches high and no more than 9 inches high.

Soft goods wrapped in paper or plastic bags and enveloped printed matter are machinable only if all packaging standards in 601 are met.

Mailers of parcels that do not conform to the machinability criteria in 7.5.1 or 7.5.2 may request authorization to mail such parcels as machinable parcels by contacting the manager, Pricing and Classification Service Center (PCSC; see 608.8.1 for address). The manager, PCSC, in conjunction with the manager, Operations Integration and Support, may authorize such parcels as machinable if the parcels are tested on NDC parcel sorters and prove to be machinable. Mailers requesting testing of parcels for machinability must:

- Submit a written request and two sample parcels to the PCSC. The request must list the mailpiece characteristics for every shape, weight, construction, and size to be considered. If the request describes a mailpiece that falls within the specifications of pieces that were tested previously, the mailpiece may not require testing.

- State the estimated number of parcels to be mailed in the next 12 months, and the anticipated preparation level (e.g., destination NDC pallets).

- Upon acknowledgment from the manager, Operations Integration and Support, the mailer may be required to send 100 mailpiece samples to the designated test facility at least 6 weeks prior to the first mailing date. The USPS may recommend changes to physical characteristics of the mailpieces, and additional testing of the redesigned pieces, before authorizing parcels as machinable.

An irregular parcel is a parcel not meeting the dimensional criteria in 7.5.1 or 7.5.2. This processing category also includes parcels that cannot be processed by NDC parcel sorters, including rolls and tubes up to 26 inches long; merchandise samples that are not individually addressed and are not letter-size or flat-size; unwrapped, paper-wrapped, or sleeve-wrapped articles that are not letter-size or flat-size; and articles enclosed in envelopes that are not letter-size, flat-size, or machinable parcels.

[1-17-16] A nonmachinable parcel is a parcel that exceeds any of the maximum dimensions for a machinable parcel. This processing category also includes high-density parcels (other than books and printed matter) weighing more than 15 pounds and exerting more than 60 pounds per square foot (0.4167 pound per square inch) pressure on their smallest side; cartons containing more than 24 ounces of liquid in one or more glass containers; cartons containing 1 gallon or more of liquid in metal or plastic containers; cans, paints; rolls and tubes longer than 26 inches; metal-band strapped boxes, metal boxes, and wood boxes; articles not mailed in boxes or other containers; harmful matter; hazardous materials except ORM-D materials; and containers with all dimensions exceeding the minimum dimensions for a machinable (regular) parcel, if their coefficient of friction or ability to slide on a smooth, hard surface is not similar to that of a domestic-class fiberboard box of the same approximate size and weight.