Overview

1.0 Standards for Intelligent Mail Barcodes

2.0 Standards for Package and Extra Service Barcodes

3.0 Standards for Barcoded Tray Labels, Sack Labels, and Container Labels

An Intelligent Mail barcode is a USPS-developed method to encode ZIP Code information on mail that can be read for sorting by automated machines. Intelligent Mail barcodes also encode other tracking information.

An Intelligent Mail barcode is the USPS-developed barcode that mailers use to encode routing and tracking information on mail that can be read by automated mail processing equipment to sort mail and to provide tracking information to the mailers. An Intelligent Mail barcode consists of 65 vertical bars, each representing one of four possible states: full bar, ascender, tracker, and descender. These 65 bars encode a string of 31 digits, divided into two parts: a 20-digit tracking code and an 11-digit routing code (when required). The 11-digit routing code may contain a ZIP Code, a ZIP+4 code, or a delivery point code, unless required to contain a certain level of code in specific applications; no correction digit is needed within an Intelligent Mail barcode. Mailers may use Intelligent Mail barcodes as follows:

- When used on letters for automation-price eligibility purposes, the routing code must contain a delivery point code that accurately matches the delivery address.

- When used on flat-size pieces for automation-price eligibility purposes, the barcode must contain a delivery point routing code that accurately matches the delivery address. When flat-size pieces bear an Intelligent Mail barcode for automation price eligibility, the barcode on a piece that contains an optional endorsement line (OEL) must contain OEL coding that includes information in Exhibit 203.7.1.1 corresponding to the correct sortation level of each bundle. When automation-priced flat-size pieces bear an Intelligent Mail barcode that contains OEL coding information corresponding to the correct sortation, an OEL is also required on the piece. See the Intelligent Mail Barcode Technical Resource Guide available on PostalPro at http://postalpro.usps.com/ for more information on incorporating OELs in Intelligent Mail barcodes.

- Reply mail pieces using origin Informed Visibility do not require a Mailer ID (MID) to be encoded into the Mailer Identifier field. All other mailpieces, including QBRM letters and PRM pieces, bearing Intelligent Mail barcodes must include the MID in the Mailer Identifier field. Additional information on Informed Visibility is available under 507.10.0. Mailers printing the Intelligent Mail barcode solely for automation price eligibility can contact the PostalOne! Help Desk at 1-800-522-9085 to obtain a MID.

Complete specifications for Intelligent Mail barcodes are defined in the Intelligent Mail Barcode Technical Resource Guide available on PostalPro at https://postalpro.usps.com. This publication also provides details on how to encode the routing code and tracking code into an Intelligent Mail barcode, barcode dimensions and spacing, clear zone, skew and rotation tolerance, and print characteristics. The assignment of a Barcode Identifier, Service Type Identifier, and Mailer ID are described by the respective publications for each extra service. These publications are available on PostalPro at https://postalpro.usps.com.

A background reflectance of at least 50% in the red portion and 45% in the green portion of the optical spectrum must be produced in the following locations when measured with a USPS or USPS-licensed envelope reflectance meter:

- The barcode clear zone of a card-size or a letter-size piece barcoded in the lower right corner.

- The area surrounding the barcode (within 1/8 inch of the leftmost and rightmost bars and 1/25 inch above and below the barcode) of a card-size, letter-size, or flat-size piece barcoded in the address block and of a flat-size, or First-Class Package Service — Retail parcel barcoded elsewhere.

A print reflectance difference (PRD) of at least 30% in the red and green portions of the optical spectrum is required between the background material of the mailpiece and the barcode, when measured with a USPS or USPS-licensed envelope reflectance meter. (PRD equals the reflectance of the background minus the reflectance of the ink.)

The material on which the barcode appears must have enough opacity to prevent printing from “showing through” to the extent that it interferes with postal equipment that reads the barcode. The print contrast ratio (PCR) of print (other than the barcode) that shows through the barcode clear zone or the barcode area in the address block must not exceed 15% when measured in the red and green portions of the optical spectrum.

Dark fibers or background patterns that produce a print contrast ratio of more than 15% when measured in the red and green portions of the optical spectrum are prohibited in these locations:

- The area of the address block or the barcode clear zone where the barcode appears on a card-size or a letter-size piece mailed at automation prices or at Enhanced Carrier Route saturation or high density prices.

- The area of the address block or the area of the mailpiece where the barcode appears on a flat-size piece in an automation mailing or on a First-Class Package Service — Retail parcel.

For a barcode on a card-size or a letter-size piece, the combined effects of positional skew (slant or tilt of the entire barcode baseline) and rotational skew (slant or tilt of the individual barcode bars) must be limited to a maximum rotation of the bars of ±5 degrees from a perpendicular to the bottom edge of the piece. The individual bars of a barcode must not shift (be vertically offset) more than 0.015 inch from the average baseline of the barcode. For information on barcode placement for card-size and letter-size pieces, see 202.5.0.

The maximum rotational skew (slant or tilt of the individual barcode bars) for barcodes is ±10 degrees from a perpendicular to the baseline of the barcode. There is no positional skew requirement. The individual bars of a barcode must not shift (be vertically offset) more than 0.015 inch from the average baseline of the barcode. For information on barcode placement for flat-size pieces, see 202.5.0. For information on barcode placement on parcels, see 202.6.0.

To help mailers evaluate the quality of their equipment producing barcodes, the USPS offers optional testing and certification to manufacturers of barcoding software and hardware. Certified barcoding equipment ensures that the equipment can produce dimensionally correct barcodes meeting postal specifications. Certification does not ensure that barcodes produced from that equipment can meet the requirements for automation prices because many other variables in barcode production (e.g., ink color and quality, paper color and contrast, equipment operation and maintenance) affect the quality of the barcodes printed on mailpieces.

Manufacturers who want their products tested and mailers who want information on available certified products should contact the National Customer Support Center (see 608.8.0 for address).

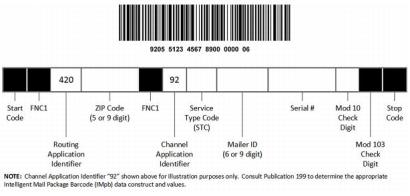

An Intelligent Mail package barcode (IMpb) is the USPS-developed barcode that can be read by automated parcel processing equipment and scanning devices, and consists of a data string that generally follows the GS1-128 specification. These barcodes include a variable length format that is determined by the elements selected by the mailer, and supplies tracking and routing data for packages and extra service applications. Intelligent Mail package barcodes must be used on all commercial packages, and on other mailpieces of customers requesting extra services. All mailers generating Intelligent Mail package barcodes (IMpb) must also submit piece-level information to USPS via an approved electronic file format (except for mailers generating barcodes for use on return services products, such as uninsured USPS Returns service packages). Electronic files must include a complete destination delivery address (which has sufficient quality to yield an 11-digit ZIP Code that matches the delivery point) and a delivery point validation (DPV) 11-digit code for all records in the file. Except for Parcel Return Service, a ZIP + 4 is required to be encoded into the barcode for all returns products.

See 202.6.1.for barcode location standards.

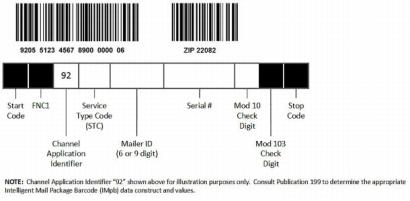

The following fields are used to construct the Intelligent Mail package barcode. Not every barcode type will use every field, and some fields may be suppressed from the human-readable text. Detailed specifications are provided in Publication 199: Intelligent Mail Package Barcode (IMpb) Implementation Guide for: Confirmation Services and Electronic Verification System (eVS) Mailers, and available on PostalPro at https://postalpro.usps.com.

- Channel Application Identifier (AI): identifies the business induction channel from which the mailpiece originated and the location of the payment record.

- Destination ZIP Code.

- Julian Date: used in conjunction with the AI to identify the print date.

- Mailer Identifier (MID): identifies the 6 or 9-digit MID of the mailer or mail service provider. A 6-digit MID must begin with a “0” through an “8” and a 9-digit MID must begin with a “9.”

- Mod 10 Check Digit: used as the final digit in the barcode string.

- Postal Code Application Identifier: identifies the presence of a routing code, when used.

- Serial Number: identifies the mailpiece, the length for which is determined by the induction channel for the mailer.

- Service Type Code: a 3-digit code that identifies the mail class, product and/or extra services.

- Source Identifier: a 2-digit field that identifies the type of online source or platform that generated the barcode.

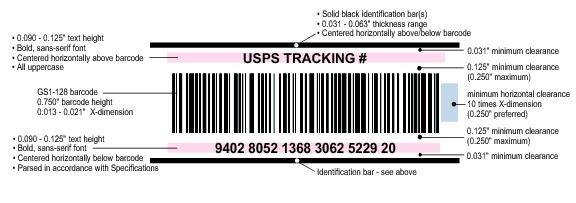

Detailed physical specifications for barcodes are provided in the resource documents and Publication 199, available on PostalPro at http://postalpro.usps.com. Physical barcode requirements are as follows:

- Barcode Symbology: generally follows GS1-128 symbology.

- X-Dimension: defines the width of the narrowest bar or space element within the barcode and must be between 0.013 inch and 0.021 inch. An X-dimension of 0.015 – 0.018 is preferred.

- Barcode Length: the overall length is a function of the number of characters encoded and the X-Dimension used.

- Barcode Height: unless allowed by exception, the minimum height must be at least 0.75 inch.

- Minimum Horizontal Barcode Quiet/Clear Zone: must measure at least ten (10) times the X-Dimension to the left and right of the barcode. A clear zone of at least 0.25 inch is recommended.

- Minimum Vertical Barcode Quiet/Clear Zone: a clear zone of at least 0.125 inch must be maintained directly above and below the barcode.

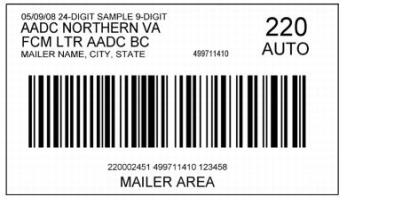

- Human-Readable Representation of Barcode Data and Service Banner: text must be printed in accordance with Exhibit 2.1.4 and as follows:

- Human-readable text cannot extend beyond the length of the identification bars.

- Service Banners must include the human-readable text “USPS SIGNATURE TRACKING #” (or “USPS SIGNATURE TRACKING NUMBER”) for mailpieces requiring a signature at delivery and ``USPS TRACKING #” (or “USPS TRACKING NUMBER”) for all other mailpieces. Service Banner text shown in Exhibit 2.1.4 is an example. See Publication 199 for additional information.

- Identification Bars: are horizontal black lines that extend at least the total combined width of the barcode and the minimum horizontal clearance to the left and right of the barcode, and may extend beyond this measurement to the width of the label are printed in accordance with Exhibit 2.1.4.

Exhibit 2.1.4 Barcode Specifications

Detailed specifications for measuring print quality are defined in the Intelligent Mail Package Barcode Specification and Publication 199.

Print quality requirements are as follows:

- Reflectance: barcodes must be printed on substrate (e.g. shipping label) of uniform color and must meet requirements for reflectance as measured on a USPS-specified reflectance meter or barcode verifier.

- Symbol Contrast: when measured in accordance with the Intelligent Mail Package Barcode Specification, must be greater than 40 percent.

- Barcode Quality: barcodes in each mailing must be 70% grade A or B with the remaining not below a grade C.

Mailers must perform routine inspections and testing of labels and barcodes to ensure quality

All mailers generating Intelligent Mail package barcodes (IMpb) must transmit piece-level information to USPS in an approved electronic file format (except for mailers generating barcodes for use on return services products, such as uninsured USPS Returns service packages). Specifications for electronic files are available on PostalPro at https://postalpro.usps.com. Electronic files must include the following elements:

- Header Record: provides summary information regarding the entity transmitting the file and the nature of the mailing.

- Detail Record 1: defines the class and service type of the item, fees and postage, destination ZIP Code and information related to containerization.

- Detail Record 2: provides detail on special products (e.g. Priority Mail Express).

- Version 1.6 (or subsequent versions) of the electronic shipping services manifest files, including each destination delivery address or ZIP + 4 Code. Shipping Services file manifests or other approved electronic documentation must include the destination delivery address (that has sufficient quality to yield an 11-digit ZIP Code that matches the delivery point) or delivery point validation (DPV) 11-digit ZIP Code for each record in the file.

- Electronic shipping manifest files, or approved alternative electronic documentation, must include data identifying the mailing agent and mail owner, as applicable.

All mailers who enter commercial parcels must meet the established thresholds for IMpb Compliance Quality outlined in Exhibit 2.1.8 to avoid an IMpb noncompliance fee. Failure to meet any compliance quality threshold in Exhibit 2.1.8 will result in the assessment of the IMpb Noncompliance Fee. For details, see Publication 199: Intelligent Mail Package Barcode (IMpb) Implementation Guide for: Confirmation Services and Electronic Verification System (eVS) Mailers available on PostalPro at https://postalpro.usps.com.

Exhibit 2.1.8 IMpbCompliance Quality Thresholds

2.1.9 Alternate Approval

Labels not meeting IMpb specifications or other label element standards, but still able to demonstrate acceptable functionality within USPS processes, may be allowed using an alternative approval process authorized by the vice president, Enterprise Analytics. (See 608.8.1 for contact information.)

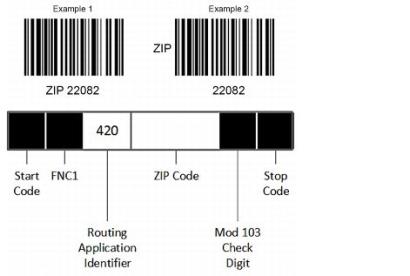

A separate postal routing barcode may be used on parcels to provide routing information, when used in conjunction with an IMpb. Each parcel must bear a properly prepared GS1-128 barcode symbology as described in 2.2.2 that accurately represents the correct ZIP Code or ZIP+4 code of the delivery address. For information on barcode placement for parcels, see 202.6.0.

GS1-Code128 postal routing barcode data elements include:

- Barcode Type. GS1-128 is the only acceptable barcode and must be printed within Subset C.

- Start Code. Postal routing barcodes must start with a Symbol Start Code, which is not shown in the human-readable text.

- Function One (FNC1). The FNC1 numeric character for GS1-128 follows the symbol start character, is part of the symbology overhead, and is not shown in the human-readable text.

- Application Identifier (AI). The AI for a postal routing barcode is “420” for domestic mail and is not shown in the human-readable text.

- ZIP Code or ZIP+4 Code. Postal routing barcodes must include the 5-digit ZIP Code or ZIP+4 code of the address. Only the 5-digit ZIP Code appears in the human-readable text.

- Check Digit. A check digit must be added at the end of the sequence of numbers to validate the authenticity of the number. GS1-128 postal routing barcodes must utilize a MOD 103 check digit, which is not shown in the human-readable text.

- Stop Code. The GS1-128 postal routing barcode must end with a Symbol Stop Code, which is not shown in the human-readable text.

Exhibit 2.2.2 Postal Routing GS1-128 Barcode Format

Eligible machinable parcels may bear a USPS Tracking or Signature Confirmation barcode using one of the following options:

- The Single Concatenated Barcode (see Exhibit 2.2.3a). Mailers may place a single concatenated barcode that combines the postal routing information and USPS Tracking or Signature Confirmation information. Single concatenated barcodes must be prepared in accordance with the technical specifications and requirements in 503 for USPS Tracking or Signature Confirmation, and in Publication 199. If a parcel bears a single concatenated barcode, then no other barcode that contains the postal routing barcode may be affixed to the package.

Exhibit 2.2.3a Confirmation Services Concatenated GS1-128 Barcode Format

- Separate Barcodes. Mailers may place both a postal routing barcode described in 2.2.2 and a USPS Tracking barcode or Signature Confirmation barcode described in 503 and in Publication 199 on the same parcel.

Exhibit 2.2.3b Confirmation Services GS1-128 Barcode Format Using a Separate Postal Routing Barcode

To eliminate the need to place one barcode for USPS Tracking or Signature Confirmation and another barcode for insurance, parcels must bear a single integrated barcode, with the correct 3-digit service type code, that combines USPS Tracking or Signature Confirmation and insurance using one of the following options:

- Single Concatenated Integrated Barcode that combines postal routing information and postal insurance (503.4.0) with USPS Tracking service or Signature Confirmation service. Single concatenated integrated barcodes must be prepared in accordance with the technical specifications and requirements in 503 for USPS Tracking and Signature Confirmation, and Publication 199. If a parcel bears a single concatenated integrated barcode then no other barcode that contains the postal routing barcode may be affixed to the package.

- Separate Barcodes. Mailers may place both a postal routing barcode described in 2.2.2 and an integrated barcode that combines insurance as described in 2.2.4a on the same parcel with USPS Tracking in 503.7.0 or Signature Confirmation in 503.8.0. The integrated barcode option allows electronic mailers to combine multiple extra services into a single barcode on their packages.

The preferred range of widths of narrow bars and spaces is 0.015 inch to 0.017 inch. The width of the narrow bars or spaces must be at least 0.013 inch but no more than 0.021 inch. All bars must be at least 0.75 inch high.

See 202.6.1 for barcode location standards.

The barcode must be located as specified in 202.6.2. No printing may appear in an area 1/8 inch above and below the barcode. A minimum clear (quiet) zone equal to 10 times the average measured narrow element (bars or space) width must be maintained to the left and right of the barcode.

Barcodes must be printed on substrate (e.g. shipping label) of uniform color and must meet requirements for reflectance as measured on a USPS-specified reflectance meter or barcode verifier.

All barcodes in each mailing must measure American National Standards Institute (ANSI) grade C or above. 70% must be grade A or B with the remaining not below a grade C.

The human-readable information on the barcode must conform to one of the following options:

- For postal routing barcodes printed under 2.2.2, 2.2.3b, and 2.2.4b, if the postal routing barcode is printed on a separate label, the human-readable equivalent of the ZIP Code or ZIP+4 code encoded in the barcode preceded by the word “ZIP” must be printed between 1/8 inch and 1/2 inch below the barcode in 10-point or larger bold sans-serif type. Alternatively, the word “ZIP” may be placed no less than 10 times the average narrow bar or space element width and no more than 1/2 inch to the left of the barcode, in 10-point or larger bold sans-serif type (see Exhibit 2.2.2). While not recommended, if the postal routing barcode is printed on the delivery address label and is in close proximity to the address, the human-readable equivalent of the ZIP Code (and the word “ZIP”) may be omitted.

- For barcodes printed under 2.2.3b or 2.2.4b the human-readable information for the concatenated or concatenated/integrated barcode must suppress the application identifiers (AI) 420 and routing ZIP Code from the human-readable text. The respective Tracking Application Identifier 92, 93, 94, or 95 must be included in the human-readable text.

Except with Certified Mail, Registered Mail, Adult Signature, Parcel Return Service, and Priority Mail Express or Priority Mail Open and Distribute services, mailers preparing extra service barcodes under 2.2 must use a “USPS TRACKING #” human-readable service banner text above the barcode on packages not requiring a signature at delivery, or a “USPS SIGNATURE TRACKING #” service banner text above the barcode on packages where a signature is required at delivery.

Postal routing codes must meet the technical specifications in the GS1-128 Application Identifier Standard, which can be obtained from Uniform Code Council Inc. (see 608.8.0), and the barcode characteristics in 2.0.

Barcodes must be printed on substrate material that preserves the optical specification as described in the AIM-USA Uniform Symbology Specification documents. Typically, white label stock commonly used for barcode generation is suitable, providing it is not glossy (causing mirror-like, specular reflection) or prone to smearing or smudging.

Intelligent Mail tray labels are the USPS-approved method to encode routing, content, origin, and mailer information on trays and sacks. Intelligent Mail tray labels are designed for optimum use with Intelligent Mail barcoded mail and have the capacity to provide unique identification throughout postal processing, but are required for use on all trays and sacks in presorted mailings.

Mailer-generated container labels bearing Intelligent Mail container barcodes identify the mail owner or agent and uniquely identify the unit (pallet, container, or rolling stock). Intelligent Mail container labels are designed for use with Intelligent Mail barcoded mail and Intelligent Mail tray labels.

- Intelligent Mail container labels are not required for small mailings of USPS Marketing Mail, Periodicals, and Bound Printed Matter letters and flats when entered at a BMEU, if the mailing is less than 500 pounds of bundles or sacks, and fewer than 72 linear feet of trays.

- Intelligent Mail container labels are not required when entering mail at a co-located BMEU within the service area where mail is entered, if the mailing consists of 100 but less than 250 pounds of bundles or sacks, and at least 12 but fewer than 35 linear feet of trays.

Exhibit 3.2.1 shows the types of mail requiring barcoded tray or sack labels. Barcoded labels must meet these general standards:

- Mailers must use the appropriate size label for the sack or tray, see 3.3 for Intelligent Mail tray and sack label standards.

- Mailer-produced barcoded labels must meet the standards in 3.0, and tray labels must be non-adhesive.

- All information on barcoded labels must be machine-printed. Alterations to preprinted barcoded labels (e.g., handwritten changes) may not be made.

- Barcoded labels must be inserted completely into the label holder on the tray or sack to prevent their loss during transport and processing.

Exhibit 3.2.1 Required Barcoded Tray and Sack Labels

The destination line must meet these standards:

- Placement. The destination line must be the top line of the label. An exception is that one line of extraneous information may appear above the destination line on tray and sack labels as provided in 3.3.2, and 3.3.3f. The destination line must be completely visible when placed in the label holder. Visibility is ensured if the destination line is no less than 1/8 (0.125) inch below the top of the label, when the label is cut and prepared.

- Information. The destination line must contain only the information required by the standards for the class, processing category, sortation level of the tray or sack, and the prices claimed. This information is contained in the labeling lists for all sortation and price levels except trays and sacks to carrier route, 5-digit carrier routes, merged 5-digit, and 5-digit destinations. For the destination line of carrier route, 5-digit carrier routes, merged 5-digit, and 5-digit trays and sacks, the city, two-letter state abbreviation, and 5-digit ZIP Code of the destination 5-digit ZIP Code area must be shown.

- Overseas Military Mail. The exact content identifier number (CIN) that matches the level of tray or sack must be used in the barcode and its numeric line on barcoded tray or sack labels. The required second line of information that corresponds to the CIN must appear on the human-readable content line of the label. The human-readable content line is automatically printed when labels are obtained through the CLDS system (clds.usps.com). A footnote at the end of the content line information means that the mailer must add appropriate information when ordering and printing tray and sack labels.

The content line must meet these standards:

- General. The content line must appear directly below the destination line as shown in 3.2.2b or 3.2.2c. This line must show the class, processing category, and the sortation level of the tray or sack as required by the applicable standards for the mailing. The appropriate content identifier number (CIN) in 3.2.4 that corresponds to that content line must be used in the barcode.

- Periodicals. Except as provided in 705.8.16 for copalletized mailings and in 207.27.2 for combined mailings, Periodicals publications must use one of the following for Line 2 class information:

- “PER.”

- “NEWS” if published weekly or more often or if authorized newspaper treatment as of March 1, 1984.

- Additional Information. For 3-digit scheme trays as specified by the labeling list, the content line for some destinations must be followed by the letter “A,” “B,” or “C,” which is not required to be right-justified. For carrier route trays and sacks, the content information must be followed by a one-letter carrier route type description followed by a space and a 3-digit route number for the route to which the tray is destined.

The exact content identifier number (CIN) that matches the level of tray or sack must be used in the barcode and its numeric line on barcoded tray or sack labels. The required second line of information that corresponds to the CIN must appear on the human-readable content line of the label. The human-readable content line is automatically printed when labels are obtained by mailers through the CLDS system (clds.usps.com). A footnote at the end of the content line information means that the mailer must add appropriate information when ordering and printing tray and sack labels. See Exhibit 3.2.4.

Exhibit 3.2.4 3-Digit Content Identifier Numbers

CLASS AND MAILING | CIN | HUMAN-READABLE CONTENT LINE |

PRIORITY MAIL EXPRESS OPEN AND DISTRIBUTE |

Dropship, all container levels | 143 | EXPRESS DROPSHIP |

Priority Mail Open and Distribute |

Dropship, all container levels | 165 | PMOD |

Letters, all classes | 029 | PMOD LTRS |

Flats, all classes | 030 | PMOD FLTS |

Parcels, all classes | 025 | PMOD PARCELS |

All Other Classes, Parcels |

DDU parcels | 031 | PMOD PARCELS DDU |

SCF parcels | 032 | PMOD PARCELS SCF |

ADC parcels | 033 | PMOD PARCELS ADC |

ASF/NDC irregular parcels | 034 | PMOD IRREG NDC |

ASF/NDC machinable parcels | 035 | PMOD MACH NDC |

First-Class Mail |

FCM Letters — Automation |

5-digit scheme trays | 241 | FCM LTR BC 5D SCHEME |

5-digit trays | 242 | FCM LTR 5D BC |

AADC trays | 245 | FCM LTR AADC BC |

mixed AADC trays | 246 | FCM LTR BC WKG |

FCM Letters — Nonautomation Machinable |

AADC trays | 258 | FCM LTR AADC MACH |

mixed AADC trays | 260 | FCM LTR MACH WKG |

FCM Letters — Presorted Nonmachinable |

5-digit trays | 267 | FCM LTR 5D MANUAL |

3-digit trays | 269 | FCM LTR 3D MANUAL |

ADC trays | 270 | FCM LTR ADC MANUAL |

mixed ADC trays | 268 | FCM LTR MANUAL WKG |

FCM Letters — Single-Piece |

single-piece trays | 260 | FCM SNGLP LTRS WKG |

FCM Flats — Automation |

5-digit trays | 272 | FCM FLTS 5D BC |

3-digit trays | 273 | FCM FLTS 3D BC |

ADC trays | 274 | FCM FLTS ADC BC |

mixed ADC trays | 275 | FCM FLTS BC WKG |

FCM Flats — Presorted |

5-digit trays | 278 | FCM FLTS 5D NON BC |

3-digit trays | 279 | FCM FLTS 3D NON BC |

ADC trays | 280 | FCM FLTS ADC NON BC |

mixed ADC trays | 282 | FCM FLTS NON BC WKG |

FCM Flats — Co-trayed Automation and Presorted |

5-digit trays | 221 | FCM FLTS 5D BC/NBC |

3-digit trays | 222 | FCM FLTS 3D BC/NBC |

ADC trays | 231 | FCM FLTS ADC BC/NBC |

mixed ADC trays | 232 | FCM FLTS BC/NBC WKG |

FCM Flats — Single-Piece |

single-piece trays | 282 | FCM SNGLP FLTS WKG |

Periodicals (PER) |

PER Letters — Carrier Route |

saturation price trays | 369 | PER LTRS WSS1 |

high density price trays | 370 | PER LTRS WSH1 |

basic price trays | 366 | PER LTRS CR1 |

5-digit carrier routes trays | 367 | PER LTRS CR-RTS |

3-digit carrier routes trays | 368 | PER LTRS 3D CR-RTS |

PER Letters — Barcoded (Automation) |

5-digit scheme trays | 341 | PER LTRS BC 5D SCHEME |

5-digit trays | 342 | PER LTRS 5D BC |

3-digit scheme trays | 343 | PER LTRS BC SCHEME2 |

3-digit trays | 344 | PER LTRS 3D BC |

AADC trays | 345 | PER LTRS AADC BC |

mixed AADC trays | 346 | PER LTRS BC WKG |

PER Letters — Nonbarcoded (Nonautomation) |

5-digit trays | 350 | PER LTRS 5D NON BC |

3-digit trays | 353 | PER LTRS 3D NON BC |

ADC trays | 356 | PER LTRS ADC NON BC |

mixed ADC trays | 359 | PER LTRS NON BC WKG |

PER Flats — Carrier Route |

car. rt. sacks — saturation | 387 | PER FLTS WSS1 |

car. rt. sacks — high density | 388 | PER FLTS WSH1 |

car. rt. sacks — basic | 385 | PER FLTS CR1 |

5-digit carrier routes sacks | 386 | PER FLTS 5D CR-RTS |

5-digit scheme car. rts. sacks | 371 | PER FLTS CR-RTS SCH |

3-digit carrier routes sacks | 351 | PER FLTS 3D CR-RTS |

PER Flats — Barcoded |

5-digit sacks | 372 | PER FLTS 5D BC |

5-digit scheme sacks | 372 | PER FLTS 5D SCH BC |

3-digit sacks | 373 | PER FLTS 3D BC |

SCF sacks | 377 | PER FLTS SCF BC |

ADC sacks or trays | 374 | PER FLTS ADC BC |

mixed ADC sacks or trays | 375 | PER FLTS BC WKG |

origin mixed ADC sacks or trays | 381 | PER FLTS WKG W FCM |

PER Flats — Nonbarcoded |

5-digit scheme sacks | 378 | PER FLT 5D SCH NON BC |

5-digit sacks | 378 | PER FLTS 5D NON BC |

3-digit sacks | 379 | PER FLTS 3D NON BC |

SCF sacks | 384 | PER FLTS SCF NON BC |

ADC sacks or trays | 380 | PER FLTS ADC NON BC |

mixed ADC sacks or trays | 382 | PER FLTS NON BC WKG |

origin mixed ADC sacks or trays | 381 | PER FLTS WKG W FCM |

PER Flats — Cosacked Barcoded and Nonbarcoded |

5-digit scheme sacks | 321 | PER FLT 5D SCH BC/NBC |

5-digit sacks | 321 | PER FLTS 5D BC/NBC |

3-digit sacks | 322 | PER FLTS 3D BC/NBC |

SCF sacks | 329 | PER FLTS SCF BC/NBC |

ADC sacks or trays | 331 | PER FLTS ADC BC/NBC |

mixed ADC sacks or trays | 332 | PER FLTS BC/NBC WKG |

origin mixed ADC sacks or trays | 381 | PER FLTS WKG W FCM |

PER Flats —

Merged Carrier Route, Barcoded, and Nonbarcoded |

merged 5-digit sacks | 339 | PER FLTS CR/5D |

merged 5-digit scheme sacks | 349 | PER FLTS CR/5D SCH |

FSS scheme | 707 | PER FLTS 5D FSS SCH BC |

FSS facility | 703 | PER FLTS 5D FSS FAC BC |

merged 3-digit sacks | 352 | PER FLTS CR/5D/3D |

PER Irregular Parcels —

Merged Carrier Route and Presorted |

merged 5-digit sacks | 340 | PER IRREG CR/5D |

merged 3-digit sacks | 354 | PER IRREG CR/5D/3D |

merged 5-digit scheme sacks | 365 | PER IRREG CR/5D SCH |

PER Irregular Parcels — Carrier Route |

saturation price sacks | 397 | PER IRREG WSS1 |

high density price sacks | 398 | PER IRREG WSH1 |

basic price sacks | 395 | PER IRREG CR1 |

5-digit carrier routes sacks | 396 | PER IRREG 5D CR-RTS |

5-digit scheme car. rts. sacks | 399 | PER IRREG CR-RTS SCH |

3-digit carrier routes sacks | 355 | PER IRREG 3D CR-RTS |

PER Irregular Parcels — Presorted |

5-digit sacks | 389 | PER IRREG 5D |

3-digit sacks | 390 | PER IRREG 3D |

SCF sacks | 394 | PER IRREG SCF |

ADC sacks or trays | 391 | PER IRREG ADC |

mixed ADC sacks or trays | 392 | PER IRREG WKG |

origin mixed ADC sacks or trays | 363 | PER IRREG WKG W FCM |

Periodicals (News) |

NEWS Letters — Carrier Route |

saturation price trays | 469 | NEWS LTRS WSS1 |

high density price trays | 470 | NEWS LTRS WSH1 |

basic price trays | 466 | NEWS LTRS CR1 |

5-digit carrier routes trays | 467 | NEWS LTRS CR-RTS |

3-digit carrier routes trays | 468 | NEWS LTRS 3D CR-RTS |

NEWS Letters — Barcoded (Automation) |

5-digit scheme trays | 441 | NEWS LTR BC 5D SCHEME |

5-digit trays | 442 | NEWS LTRS 5D BC |

3-digit scheme trays | 443 | NEWS LTRS BC SCHEME2 |

3-digit trays | 444 | NEWS LTRS 3D BC |

AADC trays | 445 | NEWS LTRS AADC BC |

mixed AADC trays | 446 | NEWS LTRS BC WKG |

NEWS Letters — Nonbarcoded (Nonautomation) |

5-digit trays | 450 | NEWS LTRS 5D NON BC |

3-digit trays | 453 | NEWS LTRS 3D NON BC |

ADC trays | 456 | NEWS LTRS ADC NON BC |

mixed ADC trays | 459 | NEWS LTRS NON BC WKG |

NEWS Flats — Carrier Route |

car. rt. sacks — saturation | 487 | NEWS FLTS WSS1 |

car. rt. sacks — high density | 488 | NEWS FLTS WSH1 |

car. rt. sacks — basic | 485 | NEWS FLTS CR1 |

5-digit carrier routes sacks | 486 | NEWS FLTS 5D CR-RTS |

5-digit scheme car. rts. sacks | 471 | NEWS FLTS CR-RTS SCH |

3-digit carrier routes sacks | 451 | NEWS FLTS 3D CR-RTS |

NEWS Flats — Barcoded |

5-digit sacks | 472 | NEWS FLTS 5D BC |

5-digit scheme sacks | 472 | NEWS FLTS 5D SCH BC |

3-digit sacks | 473 | NEWS FLTS 3D BC |

SCF sacks | 477 | NEWS FLTS SCF BC |

ADC sacks or trays | 474 | NEWS FLTS ADC BC |

mixed ADC sacks or trays | 475 | NEWS FLTS BC WKG |

origin mixed ADC sacks or trays | 481 | NEWS FLTS WKG W FCM |

NEWS Flats — Nonbarcoded |

5-digit scheme sacks | 478 | NEWS FLT 5D SCH NON BC |

5-digit sacks | 478 | NEWS FLTS 5D NON BC |

3-digit sacks | 479 | NEWS FLTS 3D NON BC |

SCF sacks | 484 | NEWS FLTS SCF NON BC |

ADC sacks or trays | 480 | NEWS FLTS ADC NON BC |

mixed ADC sacks or trays | 482 | NEWS FLTS NON BC WKG |

origin mixed ADC sacks or trays | 481 | NEWS FLTS WKG W FCM |

NEWS Flats — Cosacked Barcoded and Nonbarcoded |

5-digit scheme sacks | 421 | NEWS FLT 5D SCH BC/NBC |

5-digit sacks | 421 | NEWS FLTS 5D BC/NBC |

3-digit sacks | 422 | NEWS FLTS 3D BC/NBC |

SCF and origin/entry SCF sacks | 429 | NEWS FLTS SCF BC/NBC |

ADC sacks or trays | 431 | NEWS FLTS ADC BC/NBC |

mixed ADC sacks or trays | 432 | NEWS FLTS BC/NBC WKG |

origin mixed ADC sacks or trays | 481 | NEWS FLTS WKG W FCM |

NEWS Flats —

Merged Carrier Route, Barcoded, and Nonbarcoded |

merged 5-digit | 439 | NEWS FLTS CR/5D |

merged 5-digit scheme | 449 | NEWS FLTS CR/5D SCH |

FSS scheme | 708 | NEWS FLTS 5D FSS SCH BC |

FSS facility | 704 | NEWS FLTS 5D FSS FAC BC |

merged 3-digit sacks | 452 | NEWS FLTS CR/5D/3D |

NEWS Irregular Parcels —

Merged Carrier Route and Presorted |

merged 5-digit | 440 | NEWS IRREG CR/5D |

merged 5-digit scheme | 465 | NEWS IRREG CR/5D SCH |

merged 3-digit sacks | 454 | NEWS IRREG CR/5D/3D |

NEWS Irregular Parcels — Carrier Route |

saturation price sacks | 497 | NEWS IRREG WSS1 |

high density price sacks | 498 | NEWS IRREG WSH1 |

basic price sacks | 495 | NEWS IRREG CR1 |

5-digit carrier routes sacks | 496 | NEWS IRREG 5D CR-RTS |

5-digit scheme car. rts. sacks | 499 | NEWS IRREG CR-RTS SCH |

3-digit carrier routes sacks | 455 | NEWS IRREG 3D CR-RTS |

NEWS Irregular Parcels — Presorted |

5-digit sacks | 489 | NEWS IRREG 5D |

3-digit sacks | 490 | NEWS IRREG 3D |

SCF sacks | 494 | NEWS IRREG SCF |

ADC sacks or trays | 491 | NEWS IRREG ADC |

mixed ADC sacks or trays | 492 | NEWS IRREG WKG |

origin mixed ADC sacks or trays | 463 | NEWS IRREG WKG W FCM |

USPS MARKETING MAIL |

ECR Letters — Barcoded |

saturation price | 557 | MKT LTR BC WSS1 |

high density or high density plus price | 557 | MKT LTR BC WSH1 |

basic price | 557 | MKT LTR BC LOT1 |

5-digit carrier routes trays | 564 | MKT LTR 5D CR-RT BC |

3-digit carrier routes trays | 565 | MKT LTR 3D CR-RT BC |

ECR Letters — Nonautomation (Machinable) |

saturation price | 569 | MKT LTR MACH WSS1 |

high density or high density plus price | 569 | MKT LTR MACH WSH1 |

basic price | 569 | MKT LTR MACH LOT1 |

5-digit carrier routes trays | 567 | MKT LTR 5D CR-RT MACH |

3-digit carrier routes trays | 568 | MKT LTR 3D CR-RT MACH |

ECR Letters — Nonautomation (Nonmachinable) |

saturation price | 608 | MKT LTR MAN WSS1 |

high density or high density plus price | 608 | MKT LTR MAN WSH1 |

basic price | 608 | MKT LTR MAN LOT1 |

5-digit carrier routes trays | 609 | MKT LTR 5D CR-RT MAN |

3-digit carrier routes trays | 611 | MKT LTR 3D CR-RT MAN |

MKT Letters — Automation |

5-digit scheme trays | 541 | MKT LTR BC 5D SCHEME |

5-digit trays | 542 | MKT LTR 5D BC |

AADC trays | 545 | MKT LTR AADC BC |

mixed AADC trays | 546 | MKT LTR BC WKG |

MKT Letters — Nonautomation Machinable |

AADC trays | 558 | MKT LTR AADC MACH |

mixed AADC trays | 560 | MKT LTR MACH WKG |

MKT Letters — Presorted Nonmachinable |

5-digit trays | 604 | MKT LTR 5D MANUAL |

3-digit trays | 606 | MKT LTR 3D MANUAL |

ADC trays | 607 | MKT LTR ADC MANUAL |

mixed ADC trays | 605 | MKT LTR MANUAL WKG |

MKT Letters — Residual Pieces Subject to FCM Single-Piece Prices |

residual trays | 560 | MKT LTRS WKG |

Enhanced Carrier Route Flats — Nonautomation |

saturation price sacks | 587 | MKT FLTS ECRWSS1 |

high density or high density plus price sacks | 588 | MKT FLTS ECRWSH1 |

basic price sacks | 589 | MKT FLTS ECRLOT1 |

5-digit carrier routes sacks | 586 | MKT FLTS CR-RTS |

5-digit scheme car. rts. sacks | 529 | MKT FLTS CR-RTS SCH |

MKT Flats — Cosacked Automation and Nonautomation |

5-digit scheme sacks | 521 | MKT FLT 5D SCH BC/NBC |

5-digit sacks | 521 | MKT FLTS 5D BC/NBC |

3-digit and origin/entry 3-digit sacks | 522 | MKT FLTS 3D BC/NBC |

ADC sacks | 531 | MKT FLTS ADC BC/NBC |

mixed ADC sacks | 532 | MKT FLTS BC/NBC WKG |

MKT Flats —

Merged Carrier Route, Automation, and Presorted |

merged 5-digit | 539 | MKT FLTS CR/5D |

merged 5-digit scheme | 549 | MKT FLTS CR/5D SCH |

FSS scheme | 709 | MKT FLTS 5D FSS SCH BC |

FSS facility | 705 | MKT FLTS 5D FSS FAC BC |

MKT Flats — Automation |

5-digit sacks | 572 | MKT FLTS 5D BC |

5-digit scheme sacks | 572 | MKT FLTS 5D SCH BC |

3-digit sacks | 573 | MKT FLTS 3D BC |

ADC sacks | 574 | MKT FLTS ADC BC |

mixed ADC sacks | 575 | MKT FLTS BC WKG |

MKT Flats — Nonautomation |

5-digit scheme sacks | 578 | MKT FLT 5D SCH NON BC |

5-digit sacks | 578 | MKT FLTS 5D NON BC |

3-digit sacks | 579 | MKT FLTS 3D NON BC |

ADC sacks | 580 | MKT FLTS ADC NON BC |

mixed ADC sacks | 582 | MKT FLTS NON BC WKG |

MKT Flats — Residual Pieces Subject to FCM Single-Piece Prices |

residual sacks | 582 | MKT FLTS WKG |

Customized MarketMail (CMM) |

CMM letter trays | 206 | DEL LTR MKT CMM MAN |

CMM flat trays | 207 | DEL FLTS MKT CMM MAN |

CMM sacks | 205 | DEL MKT CMM MAN |

ECR Marketing Parcels |

saturation price sacks | 599 | MKT MKTG WSS1 |

high density price sacks | 600 | MKT MKTG WSH1 |

basic price sacks | 601 | MKT MKTG LOT1 |

5-digit carrier routes sacks | 598 | MKT MKTG CR-RTS |

MKT Marketing Parcels less than 6 oz. and Irregular Parcels |

5-digit scheme sacks | 590 | MKT IRREG 5D SCH |

5-digit sacks | 590 | MKT IRREG 5D |

SCF sacks | 596 | MKT IRREG SCF |

ASF sacks | 571 | MKT IRREG ASF |

NDC sacks | 570 | MKT IRREG NDC |

mixed NDC sacks | 594 | MKT IRREG WKG |

MKT Marketing Parcels 6 oz. or more and Machinable Parcels |

5-digit sacks | 670 | MKT MACH 5D |

5-digit scheme sacks | 670 | MKT MACH 5D SCH |

ASF sacks | 672 | MKT MACH ASF |

NDC sacks | 673 | MKT MACH NDC |

mixed NDC sacks | 674 | MKT MACH WKG |

MKT Machinable and Irregular Parcels — Presorted |

5-digit sacks | 603 | MKT MACH-IRREG 5D |

5-digit scheme sacks | 603 | MKT MACH-IRREG 5D SCH |

Package Services |

Carrier Route BPM — Flats |

carrier route sacks | 657 | PSVC FLTS CR1 |

5-digit scheme car. rts. sacks | 659 | PSVC FLTS CR-RTS SCH |

5-digit carrier routes sacks | 658 | PSVC FLTS CR-RTS |

Presorted BPM — Flats |

5-digit scheme sacks | 649 | PSVC FLTS 5D SCH NON BC |

5-digit sacks | 649 | PSVC FLTS 5D NON BC |

3-digit sacks | 650 | PSVC FLTS 3D NON BC |

SCF sacks | 654 | PSVC FLTS SCF NON BC |

ADC sacks | 651 | PSVC FLTS ADC NON BC |

mixed ADC sacks | 653 | PSVC FLTS NON BC WKG |

Presorted BPM — Automation Flats |

5-digit sacks | 635 | PSVC FLTS 5D BC |

5-digit scheme sacks | 635 | PSVC FLTS 5D SCH BC |

3-digit sacks | 636 | PSVC FLTS 3D BC |

SCF sacks | 637 | PSVC FLTS SCF BC |

ADC sacks | 638 | PSVC FLTS ADC BC |

mixed ADC sacks | 639 | PSVC FLTS BC WKG |

BPM Flats — Co-sacked Barcoded and Presorted |

5-digit scheme sacks | 648 | PSVC FLTS 5D SCH BC/NBC |

FSS scheme | 710 | PSVC FLTS 5D FSS SCH BC |

FSS facility | 706 | PSVC FLTS 5D FSS FAC BC |

5-digit sacks | 648 | PSVC FLTS 5D BC/NBC |

3-digit sacks | 661 | PSVC FLTS 3D BC/NBC |

SCF sacks | 667 | PSVC FLTS SCF BC/NBC |

ADC sacks | 668 | PSVC FLTS ADC BC/NBC |

mixed ADC sacks | 669 | PSVC FLTS BC/NBC WKG |

Carrier Route BPM — Irregular Parcels |

carrier route sacks | 697 | PSVC IRREG CR1 |

5-digit carrier routes sacks | 698 | PSVC IRREG CR-RTS |

5-digit scheme car. rt. sacks | 698 | PSVC IRREG CR-RTS SCH |

Presorted BPM — Irregular Parcels |

5-digit sacks | 690 | PSVC IRREG 5D |

5-digit scheme sacks | 690 | PSVC IRREG 5D SCH |

3-digit sacks | 691 | PSVC IRREG 3D |

SCF sacks | 696 | PSVC IRREG SCF |

ADC sacks | 692 | PSVC IRREG ADC |

mixed ADC sacks | 694 | PSVC IRREG WKG |

Carrier Route BPM — Machinable Parcels |

carrier route sacks | 687 | PSVC MACH CR1 |

Presorted BPM — Machinable Parcels |

5-digit sacks | 680 | PSVC MACH 5D |

5-digit scheme sacks | 680 | PSVC MACH 5D SCH |

ASF sacks | 682 | PSVC MACH ASF |

NDC sacks | 683 | PSVC MACH NDC |

mixed NDC sacks | 684 | PSVC MACH WKG |

Media Mail and LIbrary Mail Flats — Presorted |

5-digit sacks | 649 | PSVC FLTS 5D NON BC |

3-digit sacks | 650 | PSVC FLTS 3D NON BC |

ADC sacks | 651 | PSVC FLTS ADC NON BC |

mixed ADC sacks | 653 | PSVC FLTS NON BC WKG |

Media Mail and LIbrary Mail Irregular Parcels — Presorted |

5-digit scheme sacks | 690 | PSVC IRREG 5D SCH |

5-digit sacks | 690 | PSVC IRREG 5D |

3-digit sacks | 691 | PSVC IRREG 3D |

ADC sacks | 692 | PSVC IRREG ADC |

mixed ADC sacks | 694 | PSVC IRREG WKG |

Media Mail and Library Mail Machinable Parcels — Presorted |

5-digit scheme sacks | 680 | PSVC MACH 5D SCH |

5-digit sacks | 680 | PSVC MACH 5D |

3-digit sacks | 682 | PSVC MACH ASF |

ADC sacks | 683 | PSVC MACH NDC |

mixed ADC sacks | 684 | PSVC MACH WKG |

Parcel Select |

Parcel Select Machinable Parcels |

5-digit sacks | 680 | PSVC MACH 5D |

5-digit scheme sacks | 680 | PSVC MACH 5D SCH |

ASF sacks | 682 | PSVC MACH ASF |

NDC sacks | 683 | PSVC MACH NDC |

mixed NDC sacks | 684 | PSVC MACH WKG |

Parcel Select DSCF and DDU Prices |

5-digit sacks | 688 | PSVC PARCELS 5D |

5-digit scheme sacks | 688 | PSVC PARCELS 5D SCH |

Parcel Select — Irregular (Nonmachinable) Parcels |

3-digit sacks | 691 | PSVC IRREG 3D |

Parcel Select Lightweight Machinable Parcels |

5-digit sacks | 670 | MKT MACH 5D |

5-digit scheme sacks | 670 | MKT MACH 5D SCH |

ASF sacks | 672 | MKT MACH ASF |

NDC sacks | 673 | MKT MACH NDC |

mixed NDC sacks | 674 | MKT MACH WKG |

Parcel Select Lightweight Irregular Parcels |

5-digit sacks | 590 | MKT IRREG 5D |

5-digit scheme sacks | 590 | MKT IRREG 5D SCH |

SCF sacks | 596 | MKT IRREG SCF |

ASF sacks | 571 | MKT IRREG ASF |

NDC sacks | 570 | MKT IRREG NDC |

mixed NDC sacks | 594 | MKT IRREG WKG |

Combined Package Services and Parcel Select Parcels |

5-digit sacks | 688 | PSVC PARCELS 5D |

5-digit scheme sacks | 688 | PSVC PARCELS 5D SCH |

Combined Package Services, Parcel Select, and USPS Marketing Machinable Parcels |

5-digit sacks | 660 | MKT/PSVC MACH 5D |

5-digit scheme sacks | 660 | MKT/PSVC MACH 5D SCH |

ASF sacks | 662 | MKT/PSVC MACH ASF |

NDC sacks | 663 | MKT/PSVC MACH NDC |

mixed NDC sacks | 664 | MKT/PSVC MACH WKG |

Combined Package Services, Parcel Select, and USPS Marketing—All Parcels |

5-digit sacks | 603 | MKT/PSVC PARCELS 5D |

5-digit scheme sacks | 603 | MKT/PSVC PARCELS 5D SCH |

Combined Package Services, Parcel Select, and USPS Marketing—Irregular Parcels 2 up to 6 oz (APPS-machinable) |

3-digit sacks | 501 | MKT/PSVC 3D |

ADC sacks | 502 | MKT/PSVC ADC |

Mixed ADC sacks | 506 | MKT/PSVC WKG |

Combined PSVC & MKT—Irregular Parcels less than 2 oz, and tubes and rolls (not APPS-machinable) |

3-digit sacks | 591 | MKT/PSVC IRREG 3D |

ADC sacks | 592 | MKT/PSVC IRREG ADC |

Mixed ADC sacks | 594 | MKT/PSVC IRREG WKG |

1. This information must be followed by a one-letter carrier route type description, followed by a 3-digit route number for the route to which the tray or sack is destined. At the mailer’s option, one space is permitted between the type description and route number.

2. This information must be followed by the appropriate scheme letter A, B, or C if applicable for the destination of the tray as indicated in L002, Column B.

The origin line must appear below the content line, except as allowed under 3.3.4 and 3.2.5a and 3.2.5b. The origin line must show the city and state of the entry Post Office or the mailer‘s name and the city and state of the mailer‘s location (city and state information may be abbreviated if such abbreviations are in the USPS City State Product). A mailer code assigned by the USPS or such words as “Mailer” or “From” may appear before the required information on this line. Mailers who choose to print destination entry office information on line 3 instead of the origin information must print the origin information as follows:

- When the origin information is not printed on line 3, it must be printed right-justified in the “MAILER AREA” shown in Exhibit 3.3.2.

- When the origin information is printed in the “MAILER AREA” instead of line 3, it must be directly preceded by “ORIGIN:” or “ORGN:” and it may contain, at a minimum, the mailer‘s name and ZIP Code of origin entry.

Intelligent Mail tray labels are 2-inch labels used on trays and sacks to provide unique identification within postal processing. 24-digit Intelligent Mail tray labels include only a 24-digit barcode printed in International Symbology Specification (ISS) Code 128 subset C symbology (see Exhibit 3.3.2). Intelligent Mail tray labels also include a human readable field designed to indicate the carrier route for carrier route mailings, display an “AUTO” indicator text for automation mailings, or remain blank for nonautomation mailings. Mailers using Intelligent Mail tray labels must print labels in the 24-digit Intelligent Mail tray label format. Detailed specifications for the tray label and barcode formats are available on PostalPro at https://postalpro.usps.com.

Intelligent Mail tray labels, printed in the 24-digit format, can be used on all trays and sacks to uniquely identify each tray and sack in addition to each mailer or mail preparer. 24-digit Intelligent Mail tray labels bear a single barcode and permit an expanded mailer‘s use area (see Exhibit 3.3.2).

Exhibit 3.3.2 Intelligent Mail Tray Label

The core data elements for the Intelligent Mail tray label are as follows:

- Printer Line.

- Tray or Sack Destination (Postal destination name).

- Content Identifier Number (CIN) description (tray or sack content).

- Office of mailing or mailer information.

- Destination ZIP Code (the ZIP Code of the trays’ or sacks’ final destination).

- Carrier Route information.

- Mailer ID (unique identifier of the mailer).

- 24-digit, ISS Code 128 subset C barcode numeric line.

- Mailer area (set aside for mailer-generated human-readable information or for origin information on 24-digit Intelligent Mail tray labels when the mailer chooses to print destination entry office information on line 3 of the tray label).

The barcode composition is dependent on the Mailer ID assigned by the USPS. Upon request by the mailer, the USPS assigns a 6-digit or 9-digit Mailer ID based on the demonstrated mail volume of the mailer. Intelligent Mail tray barcodes contain the following elements:

- Destination ZIP Code.

- Content Identifier Number (CIN), as listed in Exhibit 3.2.4.

- Processing code, identifying the system or facility generating the label.

- Mailer ID.

- Serial number, a unique number assigned to each tray or sack.

- Label type, a default digit.

The Intelligent Mail tray barcode can encode a unique identifier for each tray and sack. Tray or sack serial numbers associated to an individual Mailer ID cannot be duplicated within a 45-day period, regardless of the acceptance location.

Mailers printing Intelligent Mail tray labels are responsible for the inspection and testing of the labels prior to submission to USPS and for maintaining the overall quality of the labels produced. Inspection and testing of Intelligent Mail tray labels should be performed periodically. Mailers and label vendors are encouraged to submit samples to the National Customer Service Center (NCSC) in Memphis for certification (see 608.8.0 for address).

Mailer-generated container labels bearing Intelligent Mail container barcodes identify pallets and other rolling stock, such as all-purpose containers. Intelligent Mail container barcodes uniquely identify each container and may be scanned at induction points. Detailed specifications for Intelligent Mail container barcodes and labels are available at http://postalpro.usps.gov.

Intelligent Mail container labels must be affixed on the outside of any shrinkwrap or plastic by self-adhesive or other adhesive means. Labels may be produced in two configurations:

- Affixed label measuring at least 8 inches by 11 inches. See 3.4.3 for label specifications and 3.4.5 label placement.

- Optional affixed label measuring at least 4 inches by 7 inches. See 3.4.6 for label specifications and 3.4.5 for label placement.

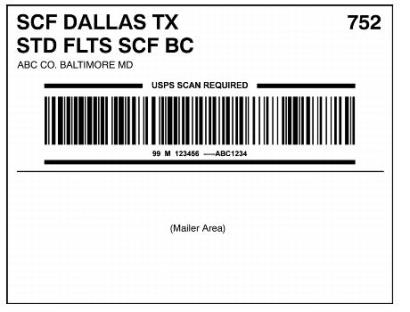

In addition to the requirements for pallet labels in 705.8.6, Intelligent Mail container labels (see Exhibit 3.4.3) must retain the top one-half of the labels for USPS-required elements, except as allowed under 705.8.6.6. The USPS banner, identification bars, and human-readable text are required elements related to the Intelligent Mail container barcode and will serve as a guide to distinguish the barcode from the other information on the container label. Required elements include:

- USPS Banner. “USPS SCAN REQUIRED” must be printed in all uppercase letters centered above the barcode and embedded within the upper identification bar. Clear zone and font size are as follows:

- A clear zone of at least 0.125 inch, but no more than 0.5 inch, must be maintained between the bottom edge of the text and the top of the barcode.

- The banner must be printed in a boldface sans-serif font of at least 14-point type.

- Identification Bars. Horizontal black bars of at least 0.10 inch thick must be printed above and below the barcode. At a minimum, the bars must extend the length of the barcode. Clear zone and other requirements are as follows:

- The upper bar must be printed at least 0.125 inch above the top edge of the barcode.

- The upper bar must have a void in the middle sufficient to insert the USPS banner without any element being obscured.

- The lower bar must be printed at least 0.125 inch below the human-readable representation of the barcode string.

- Human-Readable Representation of Barcode Data. The human-readable representation of barcode data (text) must be printed in a boldface sans-serif font of at least 12-point type. The text must not exceed the length of the barcode and must be separated by data field. Two blank character spaces must be left between each field. The text must be centered at least 0.125 inch, but no more than 0.25 inch, below the barcode.

- Barcode Location. The barcode, along with the corresponding USPS banner and identification bars, must be printed on the front side of the pallet label. When the identification bars extend beyond the length of the barcode, the barcode must be horizontally centered.

- Minimum size. The minimum size of this label is 8 inches high by 11 inches long. See additional specifications at http://postalpro.usps.gov. Mailers using larger labels must ensure the barcode conforms to the published specification and the human-readable content is provided as illustrated in Exhibit 3.4.3 and as published on the PostalPro web site.

Exhibit 3.4.3 Intelligent Mail Container Label

Intelligent Mail container barcodes are 21 characters in length and contain a USPS-assigned Mailer ID. The format depends on the Mailer ID assigned. Intelligent Mail container barcodes contain the following elements:

- Application identifier, identifying the source of the barcode.

- Type indicator, identifying internal or external label generation.

- Mailer ID.

- Serial number, a unique number assigned to each container.

Mailers may use labels bearing Intelligent Mail container barcodes only under the following conditions:

- Two labels must be affixed to each pallet as specified under 705.8.6.1.

- One label must be placed in the designated area on other USPS containers.

- Labels affixed to pallets containing Periodicals mail must be pink, except under 3.4.5d or 3.4.5e.

- Labels prepared in the optional smaller format under 3.4.6 may be white, but must include a vertical pink 1/2-inch wide identification bar along the left-hand side of the label, unless prepared under 3.4.5e.

- Labels containing Periodicals may be all white when used in conjunction with a pink designator label meeting the following criteria:

- Designator labels must be printed in landscape orientation and, except for the defined mailer-use area, must not include any print or graphics, other than the required markings in 3.4.5e2 and 3.4.5e3. Mailers may place extraneous information, meeting the criteria in 705.8.6.8, only in the mailer-use area of the label.

- The mailer-use area consists of the bottom 3 inches of designator labels measuring at least 8 inches by 11 inches, and the bottom 1 inch of designator labels measuring less than 8 inches by 11 inches. Mailers must define the mailer-use area by placing a horizontal black line of at least 0.10 inch in thickness, extending the width of the label, and must include “MAILER-USE ONLY” text printed in all uppercase letters centered and embedded within the horizontal black line. This text must be printed using boldface sans-serif font and must be in at least 14-point type.

- Designator labels must meet or exceed both the horizontal and vertical dimensions of the accompanying Intelligent Mail container label and must bear only a “PERIODICALS” or “NEWS” marking at least 1/2-inch high (or at least 48-point type).

- Designator labels may be affixed on the outside of, or be placed beneath, any shrinkwrap or plastic, but must be immediately adjacent to the Intelligent Mail container label.

- When using this option, each Intelligent Mail container label must be accompanied by an adjacent designator label.

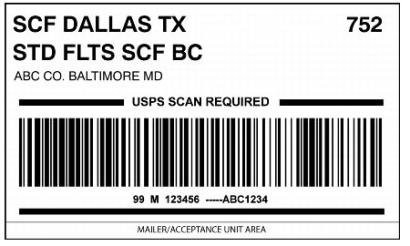

Mailers may prepare labels bearing Intelligent Mail container barcodes (see Exhibit 3.4.6) in a smaller alternate format as follows:

- Labels must include the required elements described in 705.8.6.

- Labels must measure no less than 4 inches high by 7 inches long.

- Labels prepared in the minimum size of 4 inches high by 7 inches long may include a restricted mailer/acceptance unit area that cannot exceed one line of text or contain print no larger than 12 point. Text in the restricted mailer/acceptance unit area must be restricted to the bottom line of the label (below the lower barcode identification bar).

- Intelligent Mail container labels prepared in the optional smaller format, but measuring more than 4 inches high by 7 inches long in both (or either) dimensions, must preserve the top 3.75 inches of the label, or the area including and above the lower barcode identification bar (whichever is greater), for USPS-required elements. The remainder of the label is available for restricted mailer/acceptance unit use. Text in the restricted mailer/acceptance unit area, when used, must contain print no larger than 12 point.

- All text placed in the mailer/acceptance unit area must be approved by the business mail entry unit (BMEU) servicing the mailer for acceptance and verification, except as allowed under 705.8.6.6a. or 705.8.6.6b. for optional placement of required origin office/mailer location information. Mailers wishing to include information other than that approved or allowed for use in this area must use the larger size label specified in 3.4.3.

- Two labels must be affixed to each pallet as specified under 705.8.6.1.

- Labels containing Intelligent Mail container barcodes must meet the specifications for labels posted at http://postalpro.usps.gov.

Exhibit 3.4.6 Intelligent Mail Container Label—Optional Format with Restricted Mailer Area

The Intelligent Mail container barcode can encode a unique identifier for each container. Mailers must ensure that serial numbers in barcodes remain unique for 45 days.

Mailers printing Intelligent Mail container labels are responsible for the inspection and testing of the labels prior to submission to the USPS and for maintaining the overall quality of the labels they produce. Inspection and testing of Intelligent Mail container labels should be performed periodically. Mailers are encouraged to work with their local mailpiece design analyst to validate the accuracy and quality of their labels.